excavator extension column

Applicable excavator models: Medium and large excavators of 20 tons and above

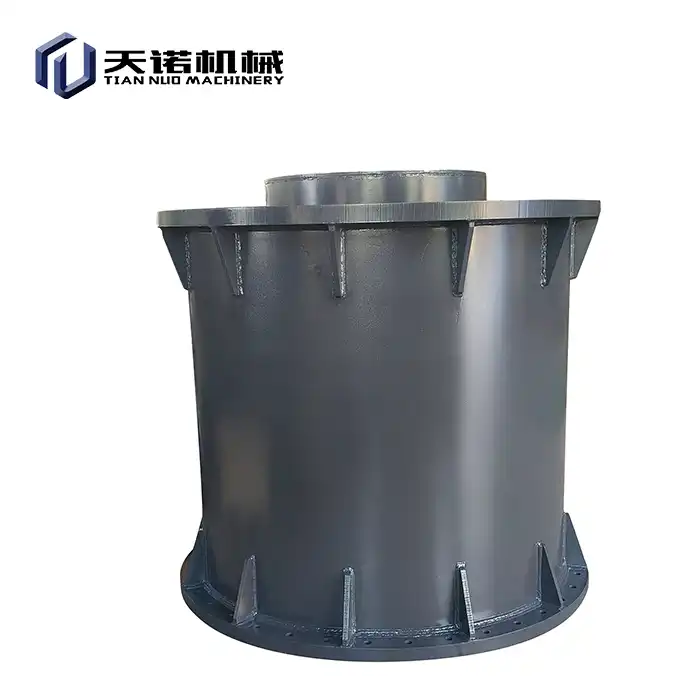

Material: High-strength alloy structural steel

- Product Description

About tiannuo machinery

With over 10 years of expertise in the railway construction and maintenance industry, Tiannuo Machinery stands as a leader in innovation and quality. Specializing in the production of advanced excavator extension column, we have earned the trust of railway companies, construction contractors, government agencies, and logistics enterprises around the world. Our commitment to delivering cutting-edge technology, exceptional support, and customized solutions ensures that your railway projects are completed efficiently, safely, and on time. Tiannuo Machinery's experience and dedication to excellence make us the ideal partner for your railway maintenance needs.

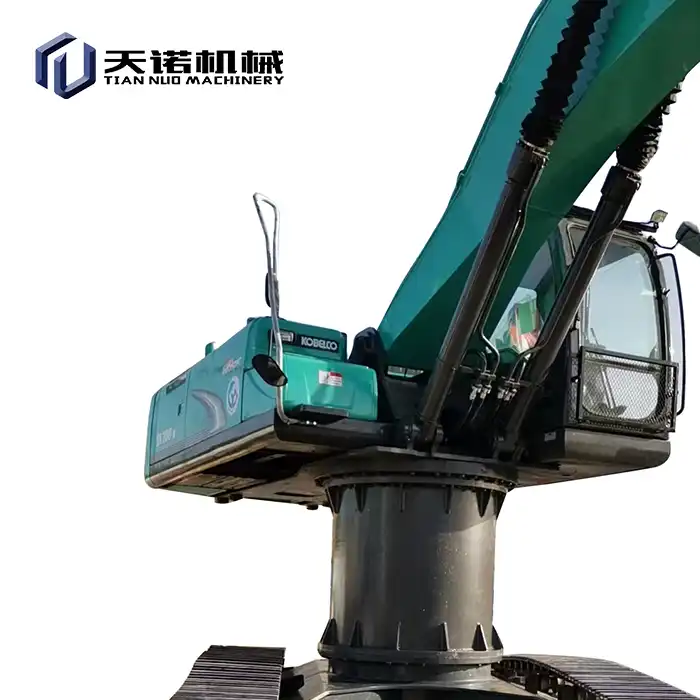

What is an excavator extension column?

"Excavator Extension Column" typically refer to booster posts used to extend or raise the working height of excavators. This type of modification is commonly used in special working conditions, such as deep foundation pit operations, high-rise building demolition, and deep pit rescue, where a larger vertical working range is required.

| use to | Extend or raise the working height of the excavator |

| mode | Medium and large excavators of 20 tons and above |

| Material | High-strength alloy structural steel |

| Manufacturing process | Box-shaped structure, full penetration welding, and overall stress relief treatment. |

Features

High-strength materials: Typically constructed from high-strength alloy plates, ensuring toughness and load-bearing capacity under high loads.

Customized design: Flexible product options are available, requiring design tailored to the specific excavator model, existing working device dimensions, and your specific operational needs (such as target height, soil type, and digging force requirements).

High safety requirements: As a critical load-bearing component, its structural design directly impacts overall machine safety and operational safety.

How It Works

Its working principle is as a "rigid extension module" between the boom and stick, proportionally amplifying the excavator's vertical working range through leverage.

The extension column itself has no independent drive component; it relies entirely on the existing boom and stick cylinders on the machine body for operation.

Workshop Display

Our manufacturing facility at Tiannuo Machinery is equipped with state-of-the-art technology and adheres to strict quality control standards. Every Ballast Blaster Undercutter we produce undergoes rigorous testing to ensure it meets our high standards of performance and durability. We take pride in delivering machines that are ready to perform from the moment they leave our workshop.

FAQ

Q: Will extending the boom affect the stability and safety of the excavator?

A: Any structural modification will affect the original machine's mechanical balance. Professional boom extension modifications ensure safety through rigorous design and calculations, but this also requires operators to strictly adhere to the new equipment's operating restrictions (such as avoiding operation on slopes, prohibiting overloading, etc.) to proactively manage risks.

Q: Will the excavator's digging force change after modification?

A: Yes. According to the lever principle, lengthening the boom will significantly reduce the actual digging force at the bucket. This means it is no longer suitable for heavy-duty digging or hard rock tunneling; its primary purpose is to expand the working range, not to increase power.

Q: Is this modification suitable for all excavator models?

A: No, this is a highly customized modification. Its feasibility depends entirely on the specific excavator model, tonnage, structural strength, and original hydraulic system capabilities. Generally, medium to large excavators of 20 tons and above are more suitable for this type of modification, and it must be implemented after evaluation by a professional manufacturer.

Q: Can the modified excavator be restored to its original state?

A: Yes, usually. Professional modifications use pin connections instead of permanent welding, allowing the booster column to be removed when not needed, restoring the excavator to its standard configuration. However, frequent disassembly and reassembly may require recalibration of the connection points.

Q: How durable are booster columns? What is their lifespan?

A: Their lifespan depends on the materials used, manufacturing process, and workload. Products made of high-strength steel and professionally heat-treated can achieve a lifespan comparable to the excavator itself under normal material handling and light to moderate digging conditions. However, frequent overloading will significantly shorten their lifespan and pose safety risks.

Contact Us

Ready to enhance your railway maintenance operations with Tiannuo Machinery’s Ballast Blaster Undercutter? Contact us today to discuss your specific needs and receive a customized solution.

Email: [arm@stnd-machinery.com]