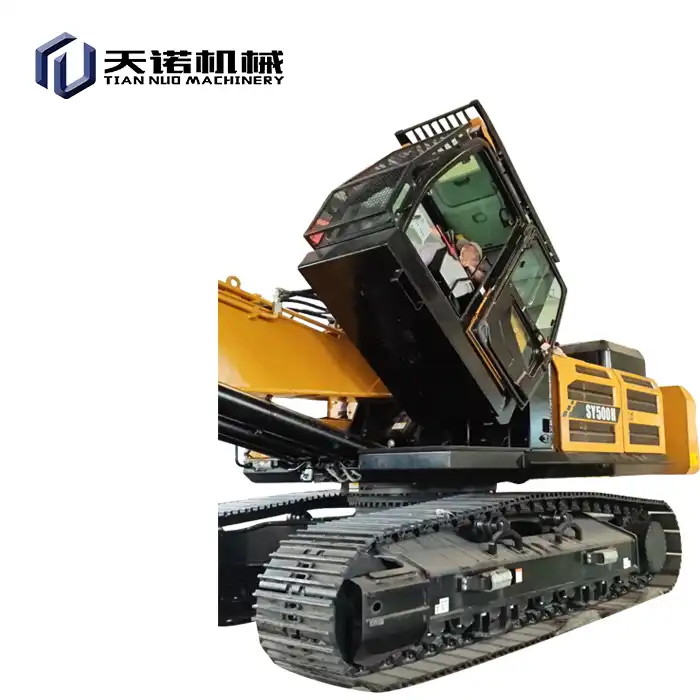

Tilting Cab for Excavators

1. Applicable models: 13-50t

2. Cab lifting height: 2500mm (customizable)

3. Cab ground clearance: 3800mm

4. Cab forward extension distance: 800mm

5. Cab field of vision: 5000-5300mm

6. Cab lifting speed: Adjustable

- Product Description

Product Overview

To address the problem of blind spots in complex working conditions such as high-altitude demolition and slope operations, we have developed an excavator tilting cab modification system. This solution utilizes a controllable forward tilting mechanism to tilt the entire cab forward, achieving a revolutionary upgrade in visibility by providing a "top-down view of the work area," thereby fundamentally improving operational safety and precision.

Core Advantages

Unobstructed View

Forward Tilt Angle: Up to 15° (customizable depending on the model)

Visibility Enhancement: Provides a direct overhead view of the area in front of and below the excavator, reducing blind spots by over 70%

Operation Method: Hydraulically driven, one-button control for tilting and resetting from the cab

Comprehensive Safety Upgrade

Reinforced Structure: Uses high-strength alloy steel modified brackets, certified to ISO 9001 rollover protection standards

Risk Prediction: Detects obstacles, personnel, or potential collapse areas in advance

Emergency Design: Automatic locking in case of power failure/malfunction, supports manual safety reset

Efficient Operation Mode

Time Saving: Single-point operation eliminates the need for repeated machine movement, increasing efficiency by approximately 30%Reduced Fuel Consumption: Reduces the frequency of equipment adjustments, resulting in a 10-15% decrease in overall fuel consumptionPrecision Control: Allows for precise observation of the work surface, especially suitable for fine demolition and high-altitude placement

Technical parameters

| Applicable models | t | 13-50 |

| Cab lifting height | mm | 2500 |

| Height of the driver's cab from the ground | mm | 3800 |

| Distance of the cab's front overhang | mm | 800 |

| Driver's field of vision | mm | 5000-5300 |

| Cab lifting speed | Adjustable |

Application Scenarios

High-rise/Dangerous Building Demolition

Provides a direct overhead view of the demolition point, avoiding the risk of falling rebar and debris, and allowing for precise control of the dismantling sequence.

High-altitude Material Handling

Allows for clear observation of lifting and placement points, achieving millimeter-level precision.

Mine Slope Trimming

Provides a direct view of the slope contour, enabling one-time trimming and reducing the number of adjustments.

Large Equipment Maintenance

Provides an overhead view of the equipment's internal structure, facilitating precise operations with small attachments.

Modification Process

Adaptation Assessment (1 working day)

On-site or online machine model inspection

Provision of modification plan and 3D simulation

Component Pre-fabrication (3-5 working days)

Customized tilting mechanism and reinforced bracket based on machine model

Pre-assembly testing

On-site Modification (1-2 days/unit)

Original cab removal → Tilting base installation → Hydraulic system integration → Control system wiring → Comprehensive testing

Delivery and Training (Half a day)

Operation training + Safety regulations + Basic maintenance guidance

Customer Testimonials

“In the old power plant demolition project, the tilting cab allowed our operators to directly see the pipeline layout below, avoiding dangerous areas in advance, and shortening the project cycle by 20%.”

— Mr. Zhang, Construction Engineering Company

“In mining slope operations, blind spots were our biggest safety hazard. After the modification, not only did the accident rate drop to zero, but the daily trimming efficiency also increased by 35%.”

— Mr. Wang, Mining Group

FAQ

Q: Will the modification affect the original machine's stability?

A: No. The modification plan is based on center of gravity simulation calculations, and counterweights are added to the corresponding positions on the chassis to ensure that the stability meets factory standards.

Q: Will the driver feel uncomfortable when the vehicle is tilted?

A: The tilting speed is gradual (approximately 1°/second), and the platform inside the driver's cab remains level (using suspension self-balancing technology), resulting in a natural operating feel.

Q: Can it be restored to its original state?

A: Yes. The modification does not damage the original vehicle structure. If restoration is needed, the tilting mechanism can be removed and the original mounting points restored.

Customize your vision upgrade solution today

Suitable for: 20-45 ton models from mainstream brands such as XCMG, Sany, Caterpillar, Komatsu, Hitachi, etc.

Contact our engineers for a customized solution.

Send your machine model and working conditions to: arm@stnd-machinery.com

_1767057467987.webp)

_1767057467845.webp)

_1767057468616.webp)