Railway Track Sweeper For Railway Maintenance

Railway track sweepers are essential tools in the realm of railway maintenance, playing a crucial role in keeping tracks clean and safe. These specialized machines are designed to remove debris, gravel, and fallen leaves from railway tracks, ensuring smooth operations and prolonging the lifespan of rail infrastructure.

Remove Gravel, Fallen Leaves and Debris

Effective debris removal is paramount for maintaining optimal railway performance. Railway track sweepers excel in this task, offering a range of features that make them indispensable for rail maintenance crews.

Efficient Cleaning with High-Power Vacuum Technology

Modern railway track sweepers utilize high-power vacuum technology to efficiently remove loose debris from tracks. This innovative approach allows for quick and thorough cleaning, minimizing disruptions to rail schedules. The powerful suction capability ensures that even small particles are effectively collected, leaving the tracks clean and free from potential obstructions.

Specialized Brushes for Tough Track Bed Debris Removal

To tackle more stubborn debris, railway track sweepers are equipped with specialized brushes. These brushes are designed to dislodge compacted materials and vegetation growth between rails and ties. The combination of rotating brushes and vacuum suction ensures a comprehensive cleaning process, addressing both surface debris and deeply embedded particles.

Eco-Friendly Debris Collection and Disposal Systems

Environmental considerations are increasingly important in railway maintenance. Modern track sweepers incorporate eco-friendly debris collection and disposal systems. These systems efficiently gather and store collected debris, allowing for proper disposal or recycling. This approach not only keeps the tracks clean but also contributes to sustainable railway maintenance practices.

The effectiveness of railway track sweepers in removing debris is crucial for maintaining safe and efficient rail operations. By keeping tracks clear of obstructions, these machines play a vital role in preventing accidents and ensuring smooth train movements.

Extend Track Life

do more than just clean; they play a crucial role in extending the life of railway infrastructure. By maintaining clean and well-maintained tracks, these machines contribute significantly to the longevity and reliability of rail networks.

Prevent Ballast Contamination and Degradation

Ballast, the crushed stone bed that supports railway tracks, is essential for proper drainage and track stability. Railway track sweepers help prevent ballast contamination by removing fine particles and debris that can infiltrate the ballast layer. This preventive action maintains the ballast's integrity, ensuring it continues to provide adequate support and drainage for the tracks.

Reduce Wear on Rails and Sleepers

Clean tracks mean less abrasive wear on rails and sleepers. By removing debris and contaminants, track sweepers help reduce the friction between train wheels and rails. This reduction in wear and tear translates to longer-lasting rails and sleepers, ultimately reducing maintenance costs and frequency of replacements.

Minimize Track Geometry Deviations

Maintaining proper track geometry is crucial for safe and comfortable train operations. Regular use of railway track sweepers helps minimize track geometry deviations by preventing the buildup of debris that can affect track alignment. This proactive approach ensures that tracks remain in optimal condition, reducing the need for frequent realignment and adjustment procedures.

The role of track sweepers in extending track life cannot be overstated. By maintaining clean and well-functioning tracks, these machines contribute to the overall efficiency and cost-effectiveness of railway operations. Their impact on track longevity makes them an invaluable asset in railway maintenance strategies.

Ensure Smooth Drainage

Proper drainage is a critical aspect of railway infrastructure maintenance, and railway track sweepers play a significant role in ensuring smooth water flow along the tracks. By keeping drainage systems clear and functional, these machines help prevent a host of issues that can arise from water accumulation.

Clear Clogged Drainage Systems for Optimal Water Flow

Railway track sweepers are equipped to clear clogged drainage systems effectively. They remove debris, sediment, and vegetation that can obstruct water channels along the tracks. This cleaning action ensures that rainwater and melting snow can flow freely, preventing water from pooling on or around the tracks. Optimal water flow is crucial for maintaining track stability and preventing erosion of the track bed.

Maintain Proper Ballast Profile for Effective Drainage

The ballast profile plays a crucial role in track drainage. Railway track sweepers help maintain the correct ballast profile by removing excess material and redistributing ballast as needed. This maintenance of the proper ballast shape and level ensures that water is efficiently directed away from the tracks, preserving the structural integrity of the railway bed.

Prevent Water Retention and Frost Heave Issues

By ensuring proper drainage, railway sweepers help prevent water retention in and around the track structure. This is particularly important in colder climates where water retention can lead to frost heave – a condition where freezing water expands and lifts the track, causing misalignment and potential safety hazards. Regular track sweeping and drainage maintenance significantly reduces the risk of these cold-weather-related issues.

The importance of smooth drainage in railway maintenance cannot be overstated. Railway track sweepers, by ensuring clear drainage paths and proper ballast profiles, contribute significantly to the overall health and longevity of railway infrastructure. Their role in preventing water-related issues is crucial for maintaining safe and reliable rail operations year-round.

Railway track sweepers are indispensable in modern railway maintenance. Their ability to efficiently remove debris, extend track life, and ensure proper drainage makes them crucial for safe and reliable rail operations. By investing in these advanced maintenance tools, railway companies can significantly improve the longevity of their infrastructure, enhance operational efficiency, and maintain high safety standards. As railway technology continues to evolve, the role of track sweepers in maintaining the backbone of rail transportation will only grow in importance.

FAQ

①How often should railway tracks be swept?

The frequency of track sweeping depends on various factors such as traffic volume, environmental conditions, and seasonal changes. Generally, high-traffic areas may require weekly sweeping, while less busy sections might need monthly maintenance.

②Can railway track sweepers operate in all weather conditions?

Most modern track sweepers are designed to operate in various weather conditions. However, extreme weather like heavy snow or flooding may limit their effectiveness and require additional measures.

③Are railway track sweepers environmentally friendly?

Many contemporary track sweepers are designed with eco-friendly features, including efficient engines, dust suppression systems, and proper debris collection mechanisms to minimize environmental impact.

④How do track sweepers contribute to rail safety?

By removing debris and maintaining proper drainage, track sweepers help prevent derailments, reduce wear on train components, and ensure tracks remain in optimal condition for safe train operations.

⑤What types of debris can track sweepers remove?

Railway track sweepers are capable of removing a wide range of debris, including leaves, gravel, metal shavings, litter, and even light snow. Some specialized models can handle heavier materials like ballast stones.

China Railway Track Sweeper Manufacturer

When considering the purchase of track sweepers, it's crucial to choose reputable manufacturers and suppliers. TianNuo Machinery offers a range of high-quality railway maintenance equipment, including efficient track sweepers. Other notable suppliers in the global market include established names in railway maintenance technology. It's advisable to compare specifications, after-sales support, and compatibility with existing equipment when making a purchase decision. Consulting with railway maintenance experts can also provide valuable insights into choosing the right track sweeper for specific operational needs.

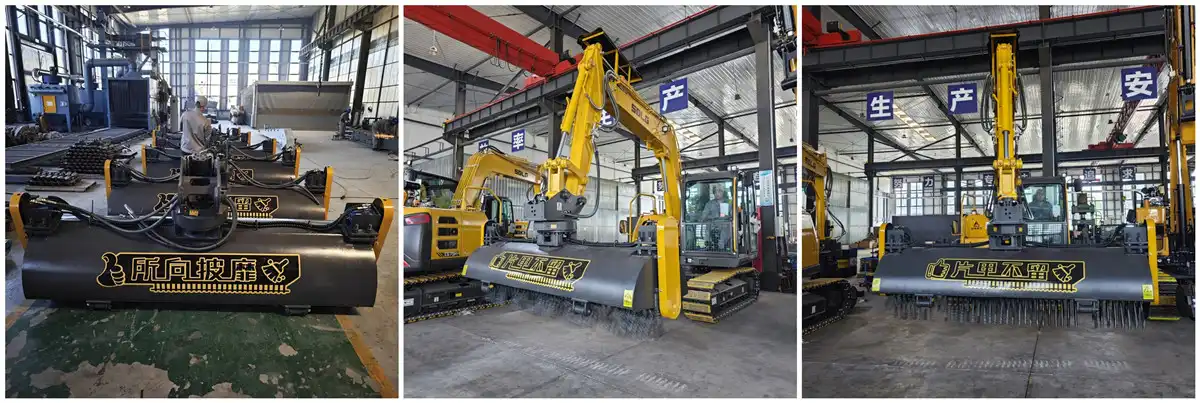

TianNuo Machinery stands out as a leading railway track sweeper manufacturer in China. Their range of products includes not only track sweepers but also comprehensive railway maintenance equipment such as sleeper changing machines, screening machines, and tamping machines. TianNuo's track sweepers are known for their efficiency and reliability, suitable for various track gauges, including 1435mm, 1520mm, and 1067mm. These sweepers are designed for use with 7-15 ton excavators and feature a 360° rotation angle, making them versatile for different maintenance scenarios. For more information on TianNuo's maintenance solutions, contact us at arm@stnd-machinery.com.

References

- International Railway Journal: "Advanced Track Maintenance Technologies"

- Railway Technology Magazine: "Innovations in Railway Track Cleaning Systems"

- Global Railway Review: "The Impact of Automated Maintenance on Rail Infrastructure"

- Journal of Rail Transport Planning & Management: "Optimizing Track Maintenance Procedures"

- Railway Track and Structures: "Best Practices in Railway Ballast Cleaning and Management"

- Transportation Research Board: "Advancements in Railway Track Sweeping Technologies"

About Author: Arm

Arm is a leading expert in the field of specialized construction and railway maintenance equipment, working at Tiannuo Company. Tiannuo specializes in manufacturing a wide range of products, including railway maintenance equipment like railway sleeper changing machines and screening machines, excavator modification equipment such as excavator lifting cabs, various engineering arms for excavators, excavator accessories like digging buckets, and engineering vehicle auxiliary equipment like loader buckets.