Excavator Rock Buckets vs. Standard Buckets: What’s the Difference?

When it comes to heavy-duty excavation, choosing the right bucket can make all the difference. Excavator rock buckets and standard buckets are two distinct tools designed for different purposes. Rock buckets, built with reinforced structures and wear-resistant materials, excel in handling tough, abrasive materials like rock and concrete. Standard buckets, on the other hand, are versatile workhorses suited for everyday digging tasks in softer soils. Understanding these differences is crucial for optimizing your excavation efficiency and equipment longevity.

Structural Strength

Reinforced Design for Rock Buckets

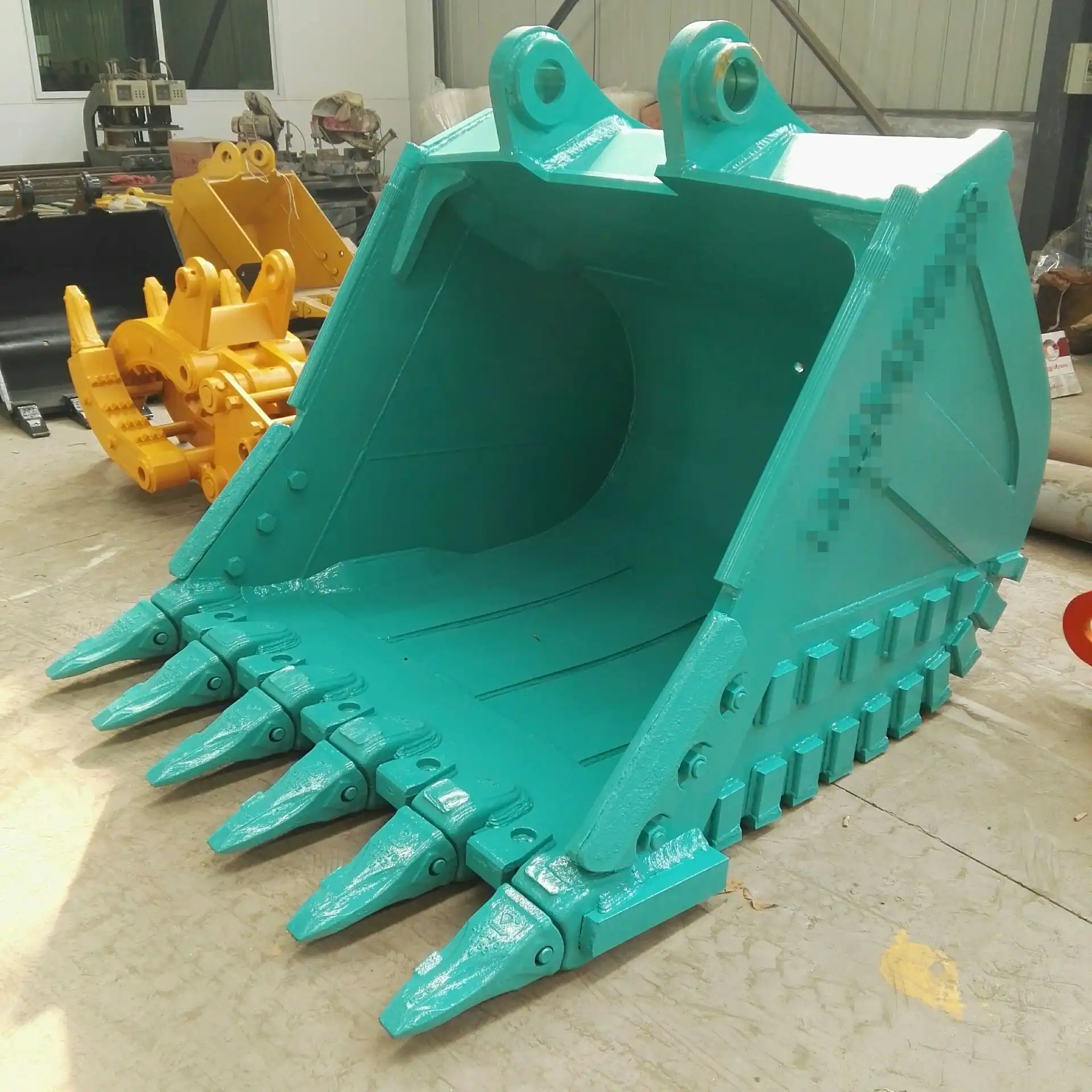

Excavator rock buckets are engineered to withstand extreme wear and tear. They feature thicker steel plates, often made from high-strength, abrasion-resistant alloys. The side plates and cutting edges are reinforced to handle the intense pressure of breaking through hard materials. This robust construction allows rock buckets to maintain their shape and effectiveness even when dealing with jagged stones and compacted earth.

Additionally, rock buckets often incorporate specialized design elements like rock guards or teeth protectors. These features shield vulnerable areas from excessive wear, prolonging the bucket's lifespan. The reinforced structure also contributes to improved digging power, allowing operators to exert more force when necessary.

Standard Buckets: Versatile but Less Durable

In contrast, standard buckets are designed for general-purpose excavation. While they're built to handle a variety of tasks, they lack the heavy-duty reinforcements found in rock buckets. The steel used in standard buckets is typically thinner, making them lighter and more maneuverable for everyday digging operations.

Standard buckets excel in tasks involving loose soil, sand, or gravel. Their design allows for quick and efficient material handling in less demanding environments. However, when faced with hard rock or concrete, standard buckets may wear out quickly or even suffer structural damage.

Impact of Wear Plates on Bucket Longevity

Both rock and standard buckets benefit from wear plates, but their application differs significantly. Excavator rock buckets often feature extensive wear plate coverage, protecting a larger surface area from abrasion. These plates are strategically placed in high-wear zones, such as the bucket floor, side plates, and cutting edge.

Standard buckets may have some wear plates, but they're typically less comprehensive. The focus is usually on protecting the cutting edge and occasional high-stress points. This difference in wear plate application directly impacts the bucket's longevity, especially in challenging environments.

Weight

Rock Buckets: Heavier for Tougher Jobs

The robust construction of excavator rock buckets inevitably leads to increased weight. This extra heft is a double-edged sword. On one hand, it provides the necessary force to break through tough materials and resist wear. The added weight allows operators to apply more pressure when digging, which is crucial when dealing with compacted or rocky terrain.

However, the increased weight of rock buckets can also impact the excavator's overall performance. It may reduce the machine's lifting capacity and reach, potentially limiting its versatility in some applications. Operators must carefully consider these trade-offs when selecting a rock bucket for their projects.

Standard Buckets: Lighter for General Use

Standard buckets, being lighter, offer several advantages in general excavation work. Their reduced weight allows for quicker cycle times, improving overall productivity in tasks that don't require heavy-duty digging power. The lighter design also puts less strain on the excavator's hydraulic system, potentially leading to better fuel efficiency and reduced wear on the machine itself.

The lighter weight of standard buckets makes them ideal for precision work and fine grading tasks. Operators can achieve better control and accuracy, especially when working in confined spaces or on delicate landscaping projects.

How Weight Affects Excavator Performance

The weight difference between rock and standard buckets significantly impacts excavator performance. Heavier excavator rock buckets may require adjustments to the excavator's counterweight to maintain stability. This can affect the machine's balance and lifting capacity, particularly when working at extended reaches.

Conversely, lighter standard buckets allow excavators to operate closer to their maximum lift capacity. This can be advantageous in projects that require frequent lifting and material placement. The reduced weight also contributes to smoother operation and potentially lower fuel consumption, which can be a significant factor in long-term project costs.

Applicable Materials

Rock Buckets: Ideal for Hard, Abrasive Materials

Excavator rock buckets shine in environments where toughness is paramount. They're the go-to choice for quarry operations, where they excel at handling large, jagged rocks and densely packed materials. In demolition projects, rock buckets prove invaluable when breaking through concrete structures or clearing debris.

These specialized buckets are also well-suited for mining applications, where they can withstand the abrasive nature of mineral extraction. Their durability makes them ideal for projects involving heavy clay soils or areas with high concentrations of gravel and stones.

Standard Buckets: Best for Soil and Softer Materials

Standard buckets are the workhorses of general construction and landscaping. They perform exceptionally well in loose to medium-density soils, making them perfect for foundation excavation, trenching, and grading work. Their design allows for efficient handling of sand, loam, and mixed earth, providing good fill factors and easy material release.

In agricultural applications, standard buckets prove their worth in tasks like land clearing and topsoil removal. Their versatility also makes them suitable for light forestry work, such as clearing underbrush or preparing sites for reforestation projects.

Choosing the Right Bucket for Your Project

Selecting between an excavator rock bucket and a standard bucket depends on a thorough assessment of your project requirements. Consider factors such as the primary material you'll be excavating, the expected duration of the project, and the specific challenges of your work site.

For projects that involve a mix of materials, it might be beneficial to have both types of buckets on hand. This allows operators to switch between them as needed, optimizing efficiency and reducing wear on equipment. In some cases, specialized buckets like skeleton buckets or screening buckets might offer the best solution for specific material handling needs.

Choosing between excavator rock buckets and standard buckets boils down to understanding your project's specific needs. Rock buckets offer unparalleled durability and performance in harsh, abrasive environments, making them ideal for quarrying, demolition, and heavy-duty excavation. Standard buckets, with their versatility and lighter weight, excel in general construction, landscaping, and soil handling tasks. By matching the right bucket to your job requirements, you can significantly enhance your excavation efficiency, reduce equipment wear, and ultimately improve your project's bottom line.

FAQ

①Can I use a standard bucket for occasional rock excavation?

While possible, it's not recommended. Standard buckets may suffer accelerated wear and potential damage when used regularly on hard, abrasive materials.

②How often should I replace wear plates on a rock bucket?

Replacement frequency depends on usage intensity and material types. Regular inspections are crucial, but typically, wear plates may need replacement every 500-1000 hours of operation in harsh conditions.

③Are there weight limits for using rock buckets on smaller excavators?

Yes, always consult your excavator's specifications. Using an overly heavy bucket can strain the machine's hydraulics and compromise stability.

④Can rock buckets be used for precision grading work?

While possible, rock buckets are less suited for fine grading due to their weight and design. Standard buckets or specialized grading buckets are better options for precision work.

⑤Is it cost-effective to invest in a rock bucket for mixed-use projects?

If your projects frequently involve hard materials, investing in a rock bucket can be cost-effective in the long run, reducing wear and tear on standard buckets and improving efficiency in tough conditions.

China Excavator Rock Bucket Supplier

TianNuo Machinery stands out as a leading manufacturer of excavator rock buckets in China. With a comprehensive range of excavator accessories and modifications, TianNuo offers solutions tailored to various industries, including railway maintenance, construction, and mining. Their rock buckets are engineered with high-strength wear-resistant steel, ensuring durability in the most challenging conditions. Available in capacities ranging from 0.2 to 5.0 cubic meters and widths from 600 to 2200 mm, these buckets can be customized to meet specific project requirements. For inquiries about their excavator specialized equipment, contact us at rich@stnd-machinery.com.

References

- Stephenson, J. (2022). Advanced Excavation Techniques in Modern Construction. Construction Equipment Guide, 37(4), 78-92.

- Caterpillar Inc. (2023). Excavator Bucket Selection Guide: Optimizing Performance and Durability. Cat Product Specifications, 12th Edition.

- Wang, L., & Smith, R. (2021). Comparative Analysis of Excavator Bucket Types in Heavy-Duty Applications. Journal of Construction Engineering and Management, 147(6), 04021046.

- TianNuo Machinery. (2023). Innovative Solutions in Excavator Attachments: A Comprehensive Overview. TianNuo Technical Report Series, Vol. 5.

- Excavator Bucket Manufacturers Association. (2022). Industry Standards for Excavator Bucket Design and Performance. EBMA Guidelines, 2022 Update.

- Johnson, K. (2023). Advancements in Wear-Resistant Materials for Mining Equipment. Mining Technology Today, 18(3), 45-59.

About Author: Arm

Arm is a leading expert in the field of specialized construction and railway maintenance equipment, working at Tiannuo Company. Tiannuo specializes in manufacturing a wide range of products, including railway maintenance equipment like railway sleeper changing machines and screening machines, excavator modification equipment such as excavator lifting cabs, various engineering arms for excavators, excavator accessories like digging buckets, and engineering vehicle auxiliary equipment like loader buckets.