How does a dustpan bucket work with an excavator?

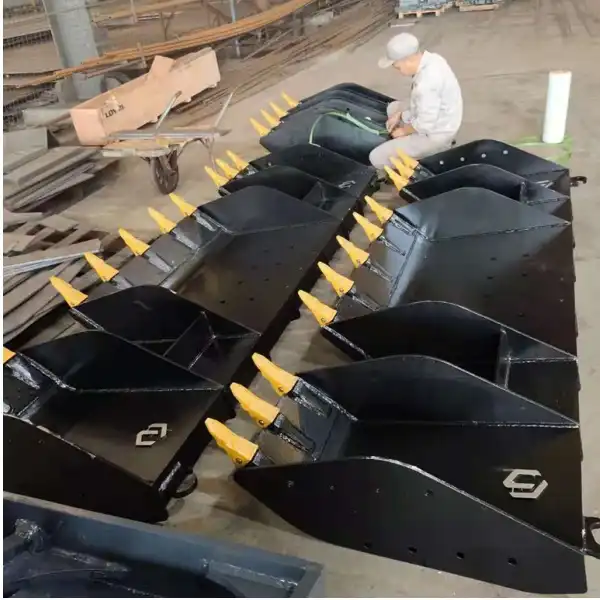

A railway excavator dustpan bucket is a specialized attachment designed to efficiently clean and maintain railway tracks. This innovative tool works seamlessly with excavators, enhancing their capabilities for track maintenance and debris removal. The dustpan bucket attaches to the excavator's arm, allowing it to scoop up ballast, debris, and other materials from between and around railway tracks. Its unique shape and design enable it to reach tight spaces, making it an essential tool for railway maintenance crews.

Quick Installation

Seamless attachment to excavator arms

The railway excavator dustpan bucket is engineered for swift and effortless installation on various excavator models. Its innovative design incorporates a universal mounting system that seamlessly connects to the excavator's arm. This streamlined attachment process minimizes downtime and maximizes productivity on the job site.

The bucket's coupling mechanism is engineered with precision, ensuring a secure and stable connection to the excavator. This robust attachment eliminates any wobbling or instability during operation, providing operators with confidence and control when maneuvering the bucket along railway tracks.

Universal fit for various excavator models

One of the key advantages of the railway excavator dustpan bucket is its versatility. Manufacturers have developed these buckets to be compatible with a wide range of excavator models, from compact machines used in urban settings to larger, more powerful excavators employed in extensive railway maintenance projects.

This universal fit allows railway maintenance teams to utilize their existing fleet of excavators without the need for extensive modifications or specialized equipment. The adaptability of the dustpan bucket ensures that companies can maximize their investment in machinery while still having access to cutting-edge track maintenance tools.

Tool-free mounting system for rapid deployment

Time is of the essence in railway maintenance, where track closures and work windows are often limited. The dustpan bucket's tool-free mounting system addresses this challenge by enabling rapid deployment in the field. Operators can quickly attach and detach the bucket without the need for additional tools or complex procedures.

This user-friendly design not only speeds up the installation process but also reduces the risk of errors or mishaps during attachment. The simplified mounting system allows maintenance crews to swiftly transition between different tasks or work sites, enhancing overall efficiency and productivity in railway maintenance operations.

The quick installation features of the railway excavator dustpan bucket contribute significantly to its effectiveness in track maintenance. By minimizing setup time and maximizing compatibility, these buckets enable maintenance crews to focus on the task at hand: keeping railway tracks clean, safe, and operational.

Easy To Operate

Intuitive controls for precise material handling

The railway excavator dustpan bucket is designed with user-friendliness in mind, featuring intuitive controls that allow operators to handle materials with exceptional precision. These controls are seamlessly integrated into the excavator's existing system, ensuring a familiar and comfortable operating experience for seasoned operators.

The bucket's responsiveness to operator input enables fine-tuned movements, crucial when working in the confined spaces of railway tracks. This precision allows for the careful removal of debris and ballast without disturbing surrounding infrastructure or compromising track integrity.

Ergonomic design for enhanced operator comfort

Comfort is key in maintaining operator productivity during long shifts of track maintenance. The ergonomic design of the dustpan bucket considers the operator's needs, reducing fatigue and strain associated with repetitive movements. The bucket's balanced weight distribution and optimized center of gravity contribute to smooth operation, minimizing the physical toll on the operator.

Additionally, the bucket's design often incorporates visibility enhancements, allowing operators to maintain a clear line of sight to the work area. This improved visibility not only increases efficiency but also contributes to safer working conditions on railway sites.

Adjustable settings for different material types

Railway maintenance involves dealing with a variety of materials, from fine gravel to larger debris. The dustpan bucket's adjustable settings allow operators to optimize performance based on the specific material being handled. These settings may include adjustable blade angles or interchangeable wear parts tailored for different types of ballast or debris.

This adaptability ensures that the bucket remains effective across a wide range of maintenance tasks, from routine cleaning to more intensive track rehabilitation projects. The ability to fine-tune the bucket's performance on-the-fly contributes to improved efficiency and reduced wear on both the bucket and the excavator.

The ease of operation provided by the railway excavator dustpan bucket not only enhances productivity but also contributes to safer and more efficient track maintenance practices. By combining intuitive controls, ergonomic design, and adaptable settings, these buckets empower operators to perform their tasks with greater skill and confidence.

Efficient Dumping

High-capacity bucket for increased productivity

The railway excavator dustpan bucket is engineered with a high-capacity design, allowing for the efficient removal of large volumes of material in a single pass. This increased capacity translates directly to improved productivity on the job site, reducing the number of cycles required to clear a section of track.

The bucket's optimized shape ensures that it can hold a substantial amount of ballast or debris while maintaining stability during operation. This balance between capacity and maneuverability is crucial in railway environments where space is often limited, and precision is paramount.

Smooth tilt mechanism for controlled material release

Effective material handling doesn't end with collection; the dumping process is equally critical. The dustpan bucket features a smooth tilt mechanism that allows for controlled release of collected materials. This precision in dumping is essential when working in railway yards or alongside active tracks, where accuracy in material placement is crucial.

The tilt mechanism is designed to provide operators with fine control over the dumping angle and speed. This level of control not only ensures accurate placement of materials but also helps prevent spillage or overfilling of dump trucks or storage areas, contributing to a cleaner and safer work environment.

Quick-release feature for rapid unloading

Time efficiency is a critical factor in railway maintenance operations, where work windows are often limited. The dustpan bucket's quick-release feature addresses this need by enabling rapid unloading of collected materials. This feature allows operators to swiftly empty the bucket's contents, minimizing downtime between collection cycles.

The quick-release mechanism is typically designed for ease of use, often activated with a single control input. This simplicity not only speeds up the unloading process but also reduces operator fatigue during repetitive dumping tasks. The efficiency gained through this feature can significantly impact the overall productivity of track maintenance operations, allowing crews to cover more ground within allocated time frames.

The efficient dumping capabilities of the railway excavator dustpan bucket play a crucial role in streamlining track maintenance processes. By combining high capacity with controlled release and rapid unloading features, these buckets enable maintenance crews to work more effectively, contributing to improved track conditions and reduced maintenance downtime.

FAQ

1. What types of materials can a railway excavator dustpan bucket handle?

Railway excavator dustpan buckets are designed to handle a variety of materials commonly found in track maintenance, including ballast, gravel, debris, and soil. They can effectively scoop up both fine and coarse materials, making them versatile tools for track cleaning and rehabilitation.

2. How does the dustpan bucket contribute to environmental sustainability in railway maintenance?

The dustpan bucket's efficient material handling and precise operation help minimize waste and reduce the environmental impact of maintenance activities. By allowing for accurate collection and placement of materials, it helps conserve resources and reduce the need for excessive ballast replacement.

3. Can the excavator dustpan bucket be used in confined spaces?

Yes, these buckets are specifically designed to operate in the confined spaces typical of railway environments. Their compact profile and precise control allow for effective cleaning and maintenance in tight areas between tracks and around railway infrastructure.

4. How does the dustpan bucket improve safety in railway maintenance operations?

The dustpan bucket enhances safety by allowing operators to work from the safety of the excavator cab while performing track maintenance tasks. Its design also minimizes the need for manual labor in potentially hazardous track areas, reducing the risk of accidents and injuries.

5. What maintenance is required for a railway excavator dustpan bucket?

Regular maintenance typically includes inspecting wear parts, such as cutting edges and teeth, and replacing them as needed. Lubrication of moving parts and checking the hydraulic connections are also important. Following the manufacturer's maintenance schedule ensures optimal performance and longevity of the bucket.

When looking to purchase railway excavator dustpan buckets, it's essential to choose a reputable supplier with a track record in railway maintenance equipment. Many heavy machinery dealerships and specialized railway equipment suppliers offer these attachments.

China Railway Excavator Dustpan Bucket

TianNuo Machinery has emerged as a leading manufacturer of railway maintenance equipment. Their product line encompasses a wide range of specialized tools designed for the unique challenges of railway maintenance. The TianNuo railway excavator dustpan bucket, with its width of 3400mm and height of 400mm, is crafted from high-strength alloy plates, ensuring durability and long-lasting performance. This robust design, coupled with 320mm openings on both sides, allows for efficient material handling in various railway applications. For more information about TianNuo's railway maintenance solutions, including excavator modification equipment and engineering arms, contact us at tn@stnd-machinery.com.

References

- TianNuo Machinery Product Catalog

- Excavator Attachment Guide

- Construction Equipment Magazine

- Mining Technology Journal

- Heavy Equipment Operator's Manual

- Railway Maintenance Equipment Standards

About Author: Arm

Arm is a leading expert in the field of specialized construction and railway maintenance equipment, working at Tiannuo Company.