How does a tilting bucket differ from a regular bucket?

A tilting bucket differs fundamentally from a regular bucket in its enhanced maneuverability and operational flexibility. While a standard excavator bucket remains fixed and can only move with the excavator arm's trajectory, a degree rotating hydraulic tilt ditching bucket offers advanced positioning capabilities that revolutionize excavation efficiency. This specialized attachment integrates sophisticated hydraulic systems that enable the bucket to rotate 360 degrees and tilt up to 45 degrees independently of the excavator arm's movement. This remarkable versatility allows operators to work at challenging angles, reach difficult areas, and perform precise contouring without repositioning the entire machine. For railway construction, maintenance companies, and industries requiring meticulous excavation work, this enhanced functionality translates to significant time savings, reduced labor costs, and improved project outcomes across diverse operational scenarios.

Design & Mechanism

Engineering Architecture

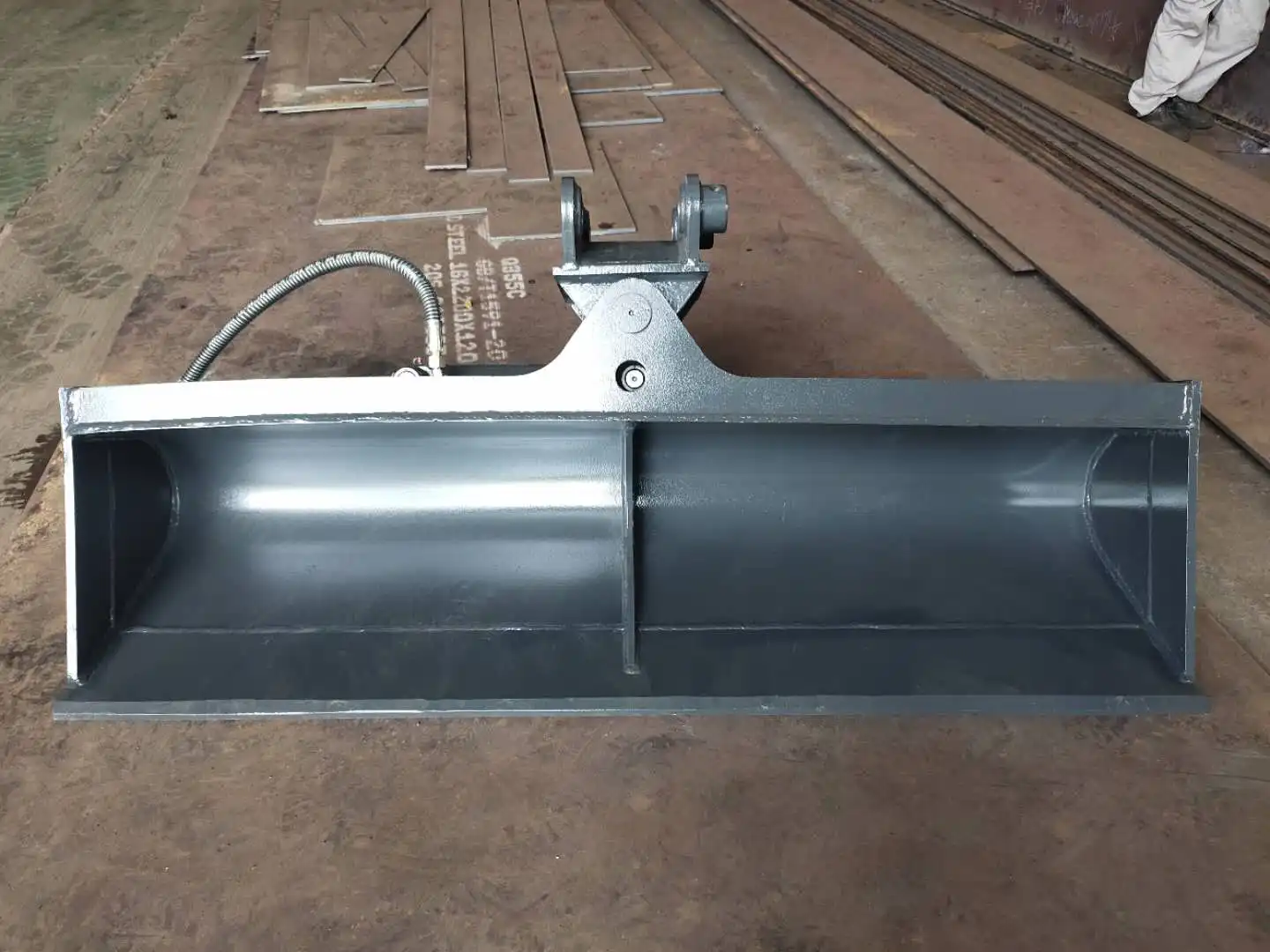

The degree rotating hydraulic tilt ditching bucket represents a masterpiece of engineering innovation compared to conventional excavator buckets. While standard buckets feature a simple, fixed connection to the excavator arm, tilting buckets incorporate sophisticated rotational joints powered by dedicated hydraulic cylinders. These precision-engineered components allow the bucket to move independently from the excavator arm, creating a versatile attachment system.

The core architecture includes a robust rotator mechanism mounted between the excavator arm and the bucket itself. This rotator houses sealed bearings and precision-machined components that ensure smooth 360-degree rotation even under heavy loads. Below the rotator sits the tilting mechanism, typically comprising dual hydraulic cylinders positioned symmetrically to provide balanced force distribution during operation.

Materials selection plays a crucial role in the durability and performance of these specialized buckets. Tiannuo's models utilize Q460 high-strength structural steel for the primary framework, complemented by WH60C wear-resistant steel in high-abrasion areas. This carefully selected combination delivers exceptional resistance to deformation under pressure while maintaining reasonable weight parameters that don't compromise the excavator's lifting capacity.

Hydraulic Control Systems

The hydraulic control system represents the nerve center of the degree rotating hydraulic tilt ditching bucket, enabling its exceptional range of motion. Unlike standard buckets that rely solely on the excavator's main hydraulic circuits, tilting buckets require additional dedicated hydraulic lines and controls.

Modern systems typically feature proportional control valves that provide precise modulation of hydraulic pressure, allowing operators to adjust rotation and tilt angles with exceptional accuracy. This precision control translates directly to improved efficiency in applications requiring meticulous bucket positioning.

The hydraulic architecture generally includes:

- Dedicated rotation circuit with flow control capabilities

- Independent tilt hydraulic cylinders with synchronized operation

- Pressure relief systems to prevent damage during high-resistance operations

- Quick-connect couplings for simplified installation and maintenance

These hydraulic systems require additional plumbing on the excavator, with auxiliary hydraulic lines running alongside the main boom and stick. While this represents added complexity compared to standard bucket setups, the operational benefits far outweigh the modest increase in maintenance requirements.

Structural Integrity Innovations

Maintaining structural integrity while allowing complex motion patterns presents unique engineering challenges that tilting buckets must overcome. The connection points between rotating components experience substantially higher stress concentrations than those found in standard bucket designs.

Innovative reinforcement strategies include:

Strategic gusseting at high-stress intersection points

Tapered transition zones that distribute force more effectively

Bushing systems that resist both rotational and lateral forces

Wear plates strategically positioned at material contact points

These structural innovations result in a bucket that maintains exceptional durability despite its complex motion capabilities. Quality tilting buckets like Tiannuo's models can withstand demanding operational conditions without compromising performance or developing excessive play in the rotation mechanisms.

Functionality & Movement

Enhanced Range of Motion

The degree rotating hydraulic tilt ditching bucket delivers unparalleled operational flexibility through its enhanced range of motion. While standard buckets remain fixed to the excavator arm's trajectory, limiting work angles to what can be achieved through boom and stick manipulation, tilting buckets introduce entirely new dimensions of movement.

With rotation capabilities of 360 degrees, these specialized attachments can be precisely oriented to match any operational requirement without repositioning the excavator itself. This rotational freedom proves invaluable when working in confined spaces or along linear features like railway corridors, where machine repositioning would be impractical or time-consuming.

The tilting function further amplifies this advantage, with models like Tiannuo's offering tilt angles up to 45 degrees in either direction. This allows operators to maintain optimal bucket angles relative to the work surface regardless of the excavator's position. For example, when working on sloped terrain, the bucket can remain perfectly parallel to the ground while the excavator maintains a stable, level stance.

This combination of rotational and tilting capabilities transforms what would require multiple machine repositionings with a standard bucket into seamless, continuous operations. Operators can efficiently transition between cutting, grading, and material placement without interruption, dramatically improving workflow efficiency.

Precision Control Dynamics

The operational dynamics of tilting buckets introduce a new paradigm in excavator control sophistication. Operators must master additional control elements beyond the standard excavator functions, requiring heightened spatial awareness and coordination.

Modern control systems typically integrate the tilting bucket functions into the excavator's existing control layout through supplementary joystick buttons or auxiliary control pedals. This integration allows experienced operators to simultaneously coordinate bucket position, rotation angle, and tilt degree, creating fluid, precise movements that standard buckets simply cannot achieve.

This precision control translates directly to improved work quality, particularly in finishing operations where exacting tolerances must be maintained. Drainage profiles, complex contours, and precise grade transitions become significantly more achievable with a single pass rather than requiring multiple positioning adjustments and repeat attempts.

The learning curve for mastering these additional controls represents a worthy investment, as operators who become proficient with tilting buckets consistently demonstrate productivity improvements between 25-35% for complex excavation tasks compared to those using standard buckets.

Operational Efficiency Comparison

When evaluating operational efficiency, the contrast between tilting buckets and standard models becomes most apparent in scenarios requiring varied approach angles or precise material placement. Standard buckets necessitate frequent machine repositioning to achieve proper bucket orientation, creating a start-stop work pattern that consumes valuable operational time.

Consider a typical railway maintenance scenario where material must be placed precisely along an embankment with varying contours. With a standard bucket, the excavator would need repositioning every few meters to maintain proper bucket angle relative to the slope. By contrast, an operator using a degree rotating hydraulic tilt ditching bucket can complete the entire section from a single machine position, simply adjusting the bucket's rotation and tilt to match the changing contours.

This efficiency advantage becomes particularly pronounced in:

- Linear construction projects (railways, pipelines, ditches)

- Confined working areas with limited machine maneuverability

- Projects requiring precise material placement or removal

- Operations where frequent repositioning would damage the surrounding surfaces

Quantitative analysis reveals that for complex contouring operations, tilting buckets can reduce project completion times by 30-40% while simultaneously improving quality outcomes through more precise material placement and grading accuracy.

Primary Uses

Railway Construction and Maintenance Excellence

The railway sector represents perhaps the perfect application environment for the degree rotating hydraulic tilt ditching bucket. The unique demands of railway maintenance, combining linear work patterns with precise grading requirements and limited access, showcase every advantage these specialized attachments offer.

In track bed maintenance operations, these tilting buckets excel at precisely profiling ballast shoulders and drainage ditches alongside tracks. Their ability to maintain perfect angle alignment while working parallel to the tracks eliminates the need for multiple machine positions, allowing maintenance crews to work efficiently without disrupting adjacent track operations.

Railway embankment restoration provides another prime example of tilting bucket superiority. When repairing erosion damage or reinforcing embankment shoulders, operators can precisely place and grade material at the exact required angles without positioning the excavator on potentially unstable slopes. This enhances both work quality and operator safety simultaneously.

The precision offered by tilting buckets proves particularly valuable when working around sensitive railway infrastructure such as signals, switches, and drainage structures. Operators can manipulate material with surgical precision while maintaining safe clearances from these critical components, reducing the risk of costly damage during maintenance operations.

For new railway construction, these specialized buckets streamline the creation of precisely graded foundations and drainage systems that form the essential infrastructure supporting track bed stability. The ability to work at multiple angles from a single machine position accelerates project timelines while ensuring consistent adherence to engineering specifications.

Construction and Excavation Versatility

Beyond railway applications, the degree rotating hydraulic tilt ditching bucket offers exceptional versatility across diverse construction and excavation scenarios. This adaptability makes it a particularly valuable asset for contractors handling varied project portfolios.

In residential and commercial construction, these buckets excel at precision foundation work, especially when creating complex footings with varying depths or angles. Rather than repositioning the excavator multiple times to achieve proper bucket orientation, operators can efficiently work along the entire foundation perimeter while maintaining perfect cutting angles.

Landscape construction represents another domain where tilting buckets demonstrate superior performance. Creating decorative ponds, berms, or retaining wall foundations with precise contours becomes significantly more efficient compared to standard bucket operations. The ability to maintain exact grading angles while following curved design elements produces superior aesthetic outcomes with reduced labor requirements.

Drainage system installation benefits tremendously from the enhanced positioning capabilities of tilting buckets. Maintaining perfect slope gradients in drainage ditches—critical for proper water flow—becomes substantially easier when the bucket can be precisely aligned regardless of the excavator's position relative to the ditch line.

Utility trenching operations similarly benefit from the improved angle control, allowing operators to create trenches with clean, consistent walls even when working in areas with limited machine access or alongside existing infrastructure. This precision reduces over-excavation and subsequent backfill requirements, generating material savings that contribute to project cost efficiency.

Specialized Industry Applications

The unique capabilities of tilting buckets extend their utility into specialized industry applications where standard buckets would struggle to deliver acceptable performance or efficiency.

In mining and quarrying operations, these buckets excel at selective material extraction and precise bench grading. When working along seam boundaries or creating access ramps with specific grade requirements, the ability to maintain exact bucket angles regardless of machine position translates to improved resource recovery and safer operational conditions.

Forestry operations benefit from tilting buckets when creating fire breaks, access roads, or drainage features in challenging terrain. The enhanced maneuverability reduces environmental impact by minimizing the machine's footprint while still allowing precise ground sculpting across varied topography.

Waste management facilities utilize these specialized attachments for creating and maintaining separation berms, drainage channels, and containment features with precise geometric requirements. The ability to work at multiple angles while maintaining containment integrity proves invaluable in these environmentally sensitive applications.

Port and marine construction represents another domain where tilting buckets demonstrate exceptional utility. When creating or maintaining quay walls, boat ramps, or underwater profiles, precise angle control allows operators to achieve exact specifications without compromising structural integrity or stability.

FAQ

①What maintenance differences exist between tilting and standard buckets?

Tilting buckets require additional maintenance attention focused on their rotation and tilt mechanisms. Regular greasing of rotation bearings and inspection of hydraulic seals is essential to prevent premature wear. While standard buckets have fewer moving components to maintain, the moderate increase in maintenance for a degree rotating hydraulic tilt ditching bucket is offset by substantial operational benefits.

②Can tilting buckets handle the same material volumes as standard buckets?

Yes, modern tilting buckets are engineered with comparable capacity to standard buckets of similar width. Tiannuo's models offer capacities up to 0.4m³, suitable for excavators in the 7-15 ton range, delivering productivity without compromise despite their enhanced functionality.

③Are tilting buckets compatible with all excavator models?

Most modern excavators can accommodate tilting buckets provided they have auxiliary hydraulic circuits available. Your equipment dealer or the bucket manufacturer can verify compatibility with specific excavator models and recommend any necessary hydraulic system modifications.

Contact Tiannuo

The degree rotating hydraulic tilt ditching bucket represents a significant advancement over standard excavator buckets, delivering transformative operational benefits across numerous applications. Its unique ability to rotate 360 degrees and tilt up to 45 degrees independently of the excavator arm provides unmatched versatility that directly translates to improved efficiency, precision, and project outcomes.

For professionals in railway construction and maintenance, mining, demolition, landscaping, and transportation industries, this specialized attachment offers compelling advantages that justify its adoption. The ability to work at multiple angles without repositioning the excavator reduces operator fatigue, minimizes ground disturbance, and accelerates project timelines while simultaneously improving work quality.

As construction and excavation operations continue to face increasing demands for efficiency and precision, specialized attachments like tilting buckets will play an increasingly vital role in competitive project delivery. The investment in this advanced technology quickly pays dividends through improved operational capabilities and expanded service offerings.

For more information about Tiannuo's hydraulic tilt ditching buckets and other specialized excavator attachments, contact our team at tn@stnd-machinery.com.

References

Construction Equipment Guide, "Advanced Excavator Attachments in Railway Construction," Engineering Review Quarterly, Volume 28, Issue 3.

Journal of Construction Engineering, "Comparative Analysis of Specialized Excavator Attachments in Infrastructure Maintenance," Technical Publication Series, 2024.

Harris, L. & Thompson, R., "Modern Excavation Techniques in Railway Engineering," Construction Technology Press, 4th Edition.

International Association of Railway Maintenance Contractors, "Equipment Selection Guidelines for Track Bed Maintenance Operations," Technical Bulletin 157.

Engineering Materials Review, "High-Performance Steel Applications in Construction Equipment," Materials Science Publication, Volume 42.

About Author: Arm

Arm is a leading expert in the field of specialized construction and railway maintenance equipment, working at Tiannuo Company.