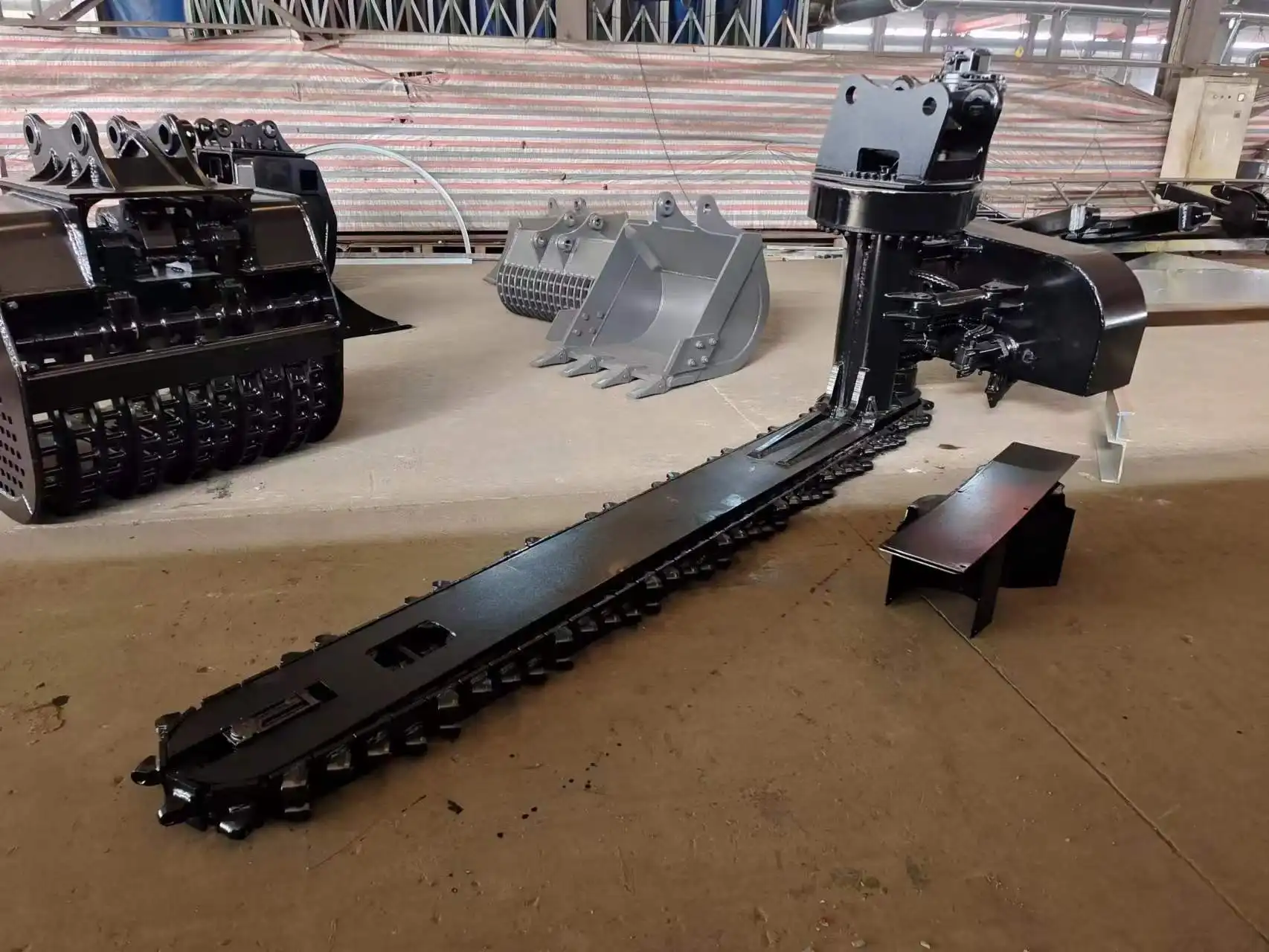

Rail-Road Undercutter Excavators with 360° Rotation Capabilities

When railway maintenance crews face the challenging task of removing fouled ballast from beneath active rail lines, traditional equipment often falls short of delivering the precision and efficiency required. The rail-road ballast undercutter excavator with 360° rotation capabilities represents a revolutionary advancement in railway maintenance technology. These specialized machines combine the power of conventional excavators with innovative rotating mechanisms that enable operators to work seamlessly from either side of the tracks while maintaining optimal positioning for ballast extraction. Unlike standard undercutting equipment that limits operational flexibility, these advanced systems provide continuous rotation functionality that dramatically improves spoil pile management and reduces project completion times. The integration of full-rotation capabilities transforms how maintenance teams approach ballast renewal projects, offering unprecedented versatility in confined railway environments where space constraints traditionally hampered efficient operations.

Definition and Core Functionality

Understanding Railway Ballast Undercutting Technology

Railway ballast undercutting represents a specialized maintenance procedure that involves the precise removal of contaminated or degraded ballast material from beneath existing rail tracks without disrupting the structural integrity of the railway system. This process becomes essential when ballast loses its drainage properties due to fine particle contamination, organic matter accumulation, or general deterioration from repeated loading cycles.

The undercutting mechanism operates through a sophisticated chain-driven system featuring hardened steel teeth that penetrate beneath the sleeper level, typically reaching depths of 600-800mm below the rail formation. These cutting chains rotate at controlled speeds, typically ranging from 30-60 revolutions per minute, ensuring optimal material extraction while minimizing track bed disturbance.

Excavator Integration and Mounting Systems

Modern undercutting attachments integrate seamlessly with railway-compatible excavators through various coupling mechanisms, including traditional pin-grab systems and advanced tiltrotator interfaces. The mounting configuration allows the undercutter to function as a specialized hydraulic attachment, drawing power directly from the excavator's hydraulic system while maintaining independent operational control.

The hydraulic integration typically requires flow rates of 80-150 liters per minute at operating pressures between 200-250 bar, depending on the undercutter size and cutting requirements. This hydraulic demand necessitates careful matching between the attachment specifications and the host excavator's hydraulic capacity to ensure optimal performance.

Material Processing and Separation Capabilities

The undercutting process involves simultaneous cutting and lifting actions that extract fouled ballast while allowing clean material to remain in place. Advanced undercutters incorporate screening mechanisms that separate reusable ballast from contaminated material during the extraction process, reducing waste and improving project economics.

These systems can process various ballast types, including traditional granite and limestone aggregates, recycled concrete ballast, and specialized materials used in high-speed rail applications. The cutting depth adjustment capabilities enable operators to target specific contamination layers while preserving the underlying formation structure.

Key Advantages of 360° Rotation

Enhanced Operational Flexibility and Positioning

The incorporation of continuous 360° rotation functionality transforms traditional undercutting operations by eliminating the positioning constraints that typically limit conventional equipment. Operators can now approach ballast removal tasks from optimal angles regardless of track orientation or surrounding infrastructure limitations.

This rotational capability proves particularly valuable in complex railway environments where multiple tracks, overhead structures, or adjacent platforms restrict conventional equipment movement. The ability to rotate the undercutter continuously allows operators to work efficiently in tight spaces while maintaining proper cutting angles and material flow patterns.

Improved Spoil Management and Material Handling

Traditional undercutting operations often struggle with efficient spoil pile management, particularly in confined spaces where extracted material must be carefully positioned to avoid interference with ongoing operations. The rail-road ballast undercutter excavator with 360° rotation addresses this challenge by enabling precise control over extracted material placement.

Operators can continuously adjust the discharge direction without repositioning the entire machine, creating organized spoil piles that facilitate subsequent material handling operations. This capability reduces cycle times by minimizing the need for additional equipment movements and enables more strategic placement of extracted materials for efficient removal or processing.

Reduced Setup Time and Increased Productivity

The flexibility provided by continuous rotation significantly reduces the setup time required for each undercutting section. Traditional equipment often requires multiple positioning adjustments to achieve optimal cutting angles, consuming valuable track possession time that railway operators carefully manage.

With 360° rotation capabilities, operators can maintain continuous cutting operations while adjusting their approach angle to accommodate varying track conditions, sleeper spacing, or contamination patterns. This adaptability translates directly into improved productivity rates, with some operations reporting 25-40% reductions in project completion times compared to conventional undercutting methods.

Technical Design and Components

Rotary Bearing Systems and Structural Engineering

The engineering foundation of 360° rotation capability lies in sophisticated rotary bearing systems designed to withstand the extreme forces encountered during ballast undercutting operations. These bearings must accommodate both the cutting loads generated by the undercutter chains and the dynamic forces created by material extraction and discharge.

High-capacity slewing bearings, typically featuring four-point contact ball configurations or crossed roller designs, provide the structural foundation for continuous rotation while maintaining precise positioning accuracy. These bearings incorporate advanced sealing systems to prevent contamination from ballast dust and moisture, ensuring reliable operation in harsh railway environments.

Hydraulic Motor Integration and Power Transmission

The rotation mechanism relies on precision hydraulic motors that deliver controlled rotational movement while maintaining sufficient torque to overcome operational resistance. These motors typically feature displacement ranges from 250-500 cc/rev, providing the power density required for smooth rotation under load.

The power transmission system incorporates reduction gearing that matches the motor characteristics to the rotational requirements of the undercutter assembly. Gear ratios typically range from 50:1 to 100:1, providing the low-speed, high-torque characteristics necessary for precise positioning control while maintaining adequate rotation speed for operational efficiency.

Control Systems and Operator Interface

Modern rail-road ballast undercutter excavator systems incorporate sophisticated control interfaces that enable operators to manage both cutting and rotation functions through integrated joystick controls or touchscreen displays. These systems provide real-time feedback on cutting depth, rotation position, and hydraulic parameters.

Advanced control systems include programmable rotation limits, automatic positioning sequences, and safety interlocks that prevent equipment damage during operation. Some systems incorporate GPS positioning integration that enables automatic positioning based on predetermined cutting patterns, reducing operator workload and improving consistency.

FAQ

①What excavator sizes are compatible with 360° rotation undercutters?

Most rail-road ballast undercutter excavator attachments with 360° rotation are designed for excavators in the 14-24 ton operating weight range, though larger units can accommodate excavators up to 35 tons. The hydraulic requirements typically need 80-150 L/min flow capacity.

②How deep can these undercutters penetrate beneath the tracks?

Standard undercutting depth ranges from 500-800mm below the sleeper base, with some specialized units capable of reaching 1000mm depths. The actual penetration depends on ballast conditions and specific project requirements.

③What maintenance is required for the rotation mechanism?

Regular maintenance includes hydraulic fluid changes every 500 operating hours, bearing lubrication according to manufacturer specifications, and periodic inspection of sealing systems to prevent contamination ingress.

④Can these systems work on different rail gauges?

Most modern undercutters accommodate standard gauge (1435mm) applications, with customization available for narrow gauge or broad gauge railways. The cutting width is typically adjustable between 500-1200mm to match various track configurations.

⑤What are the typical operating speeds for undercutting work?

Undercutting operations typically proceed at 0.5-1.2 km/h, depending on ballast conditions, contamination levels, and required cutting depth. The rotation capability allows operators to maintain consistent speeds while adjusting to track variations.

The evolution of railway maintenance technology continues to push boundaries in efficiency and capability, with rail-road ballast undercutter excavator systems representing the pinnacle of modern ballast management solutions. These advanced machines combine proven undercutting principles with innovative 360° rotation technology to deliver unprecedented operational flexibility and productivity gains. The integration of continuous rotation capabilities addresses longstanding challenges in confined railway environments while reducing project timelines and improving maintenance quality. As railway networks worldwide face increasing demands for rapid, efficient maintenance solutions, these versatile systems provide the technological foundation for meeting tomorrow's infrastructure challenges. For detailed specifications on TianNuo Machinery's comprehensive range of railway maintenance equipment, including customizable ballast undercutter excavator solutions designed to meet your specific operational requirements, contact our technical specialists at tn@stnd-machinery.com.

References

- Railway Engineering Handbook: Modern Ballast Maintenance Technologies and Equipment Applications, Third Edition, International Railway Engineering Association, 2023.

- Hydraulic Attachment Systems for Railway Construction Equipment: Design Principles and Performance Optimization, Journal of Railway Mechanical Engineering, Volume 47, Issue 3, 2024.

- Advanced Ballast Undercutting Techniques: Comparative Analysis of Rotational vs. Fixed Position Systems, Railway Maintenance Technology Quarterly, Spring 2024 Edition.

- Excavator-Based Railway Maintenance Equipment: Technical Specifications and Operational Guidelines, European Railway Equipment Standards Commission, Document ER-2024-15.

- Cost-Benefit Analysis of 360-Degree Rotation Capabilities in Railway Ballast Management Systems, Transportation Infrastructure Economics Review, Volume 12, Number 2, 2024.

About Author: Arm

Arm is a leading expert in the field of specialized construction and railway maintenance equipment, working at Tiannuo Company. Tiannuo specializes in manufacturing a wide range of products, including railway maintenance equipment like railway sleeper changing machines and screening machines, excavator modification equipment such as excavator lifting cabs, various engineering arms for excavators, excavator accessories like digging buckets, and engineering vehicle auxiliary equipment like loader buckets.