Railroad Maintenance Attachments for Sleeper Handling

Railroad maintenance attachments play a crucial role in keeping our railway infrastructure safe and efficient. These specialized tools are designed to handle sleepers (also known as ties) with precision and care. From tie inserters to sleeper grabs and changers, these attachments streamline the process of installing, removing, and replacing sleepers. By investing in high-quality railroad maintenance machines, railway companies can significantly improve their track maintenance operations, reduce downtime, and ensure smoother, safer train journeys for passengers and freight alike.

Tie Inserter

Efficient Sleeper Placement with Modern Tie Inserters

Modern tie inserters have revolutionized the way we install and change railroad sleepers. These powerful machines can quickly and accurately position new ties, significantly reducing the time and labor required for track maintenance. With advanced hydraulic systems and precise control mechanisms, tie inserters can handle various sleeper materials, including wood, concrete, and composite ties.

One of the key advantages of using tie inserters is their ability to work in confined spaces and challenging terrain. These versatile attachments can be mounted on excavators or specialized rail vehicles, allowing maintenance crews to access hard-to-reach areas of the track. This flexibility is particularly valuable for railway companies operating in urban environments or mountainous regions where traditional maintenance equipment may struggle to maneuver.

Choosing the Right Tie Inserter for Your Railway Project

Selecting the appropriate tie inserter for your specific needs is crucial for maximizing efficiency and productivity. Consider factors such as the type of sleepers you'll be working with, the volume of ties to be inserted, and the terrain conditions of your railway network. Some tie inserters are designed for high-speed operations on mainline tracks, while others are better suited for yard work or short-line railroads.

When evaluating tie inserters, pay close attention to features like lifting capacity, reach, and cycle time. These specifications will determine how quickly and effectively the machine can insert sleepers. Additionally, look for models with user-friendly controls and ergonomic designs that reduce operator fatigue during long shifts.

Maintenance Tips to Extend Your Tie Inserter's Lifespan

Proper maintenance is essential for keeping your tie inserter in top condition and ensuring its longevity. Regular inspections and preventive maintenance can help identify potential issues before they become major problems, saving you time and money in the long run. Here are some key maintenance tips to keep in mind:

- Lubricate moving parts regularly according to the manufacturer's recommendations

- Check hydraulic systems for leaks and maintain proper fluid levels

- Inspect and replace worn components promptly

- Keep the machine clean and free from debris

- Train operators on proper usage and handling techniques

By following these maintenance practices, you can extend the lifespan of your tie inserter and minimize unexpected downtime during critical maintenance operations.

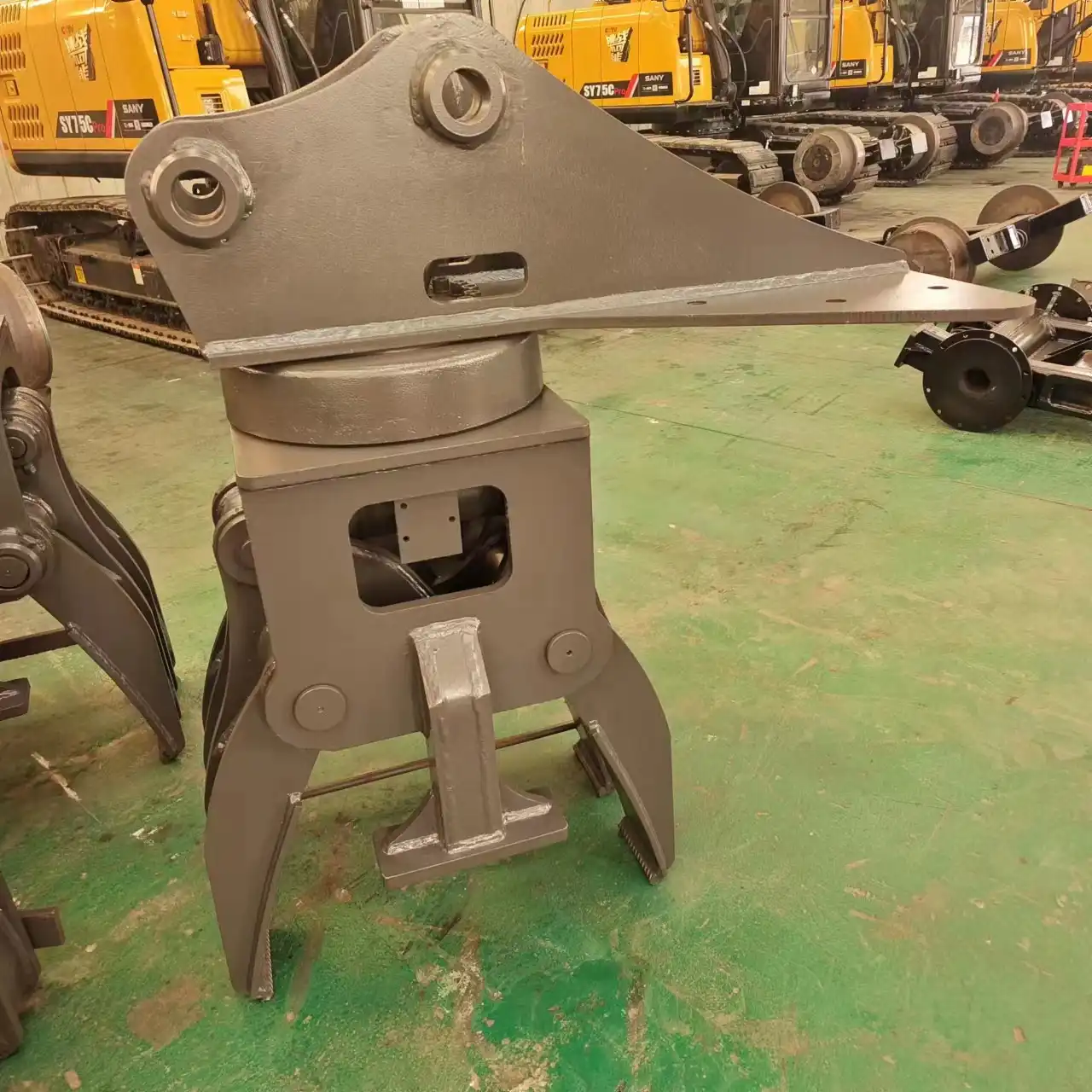

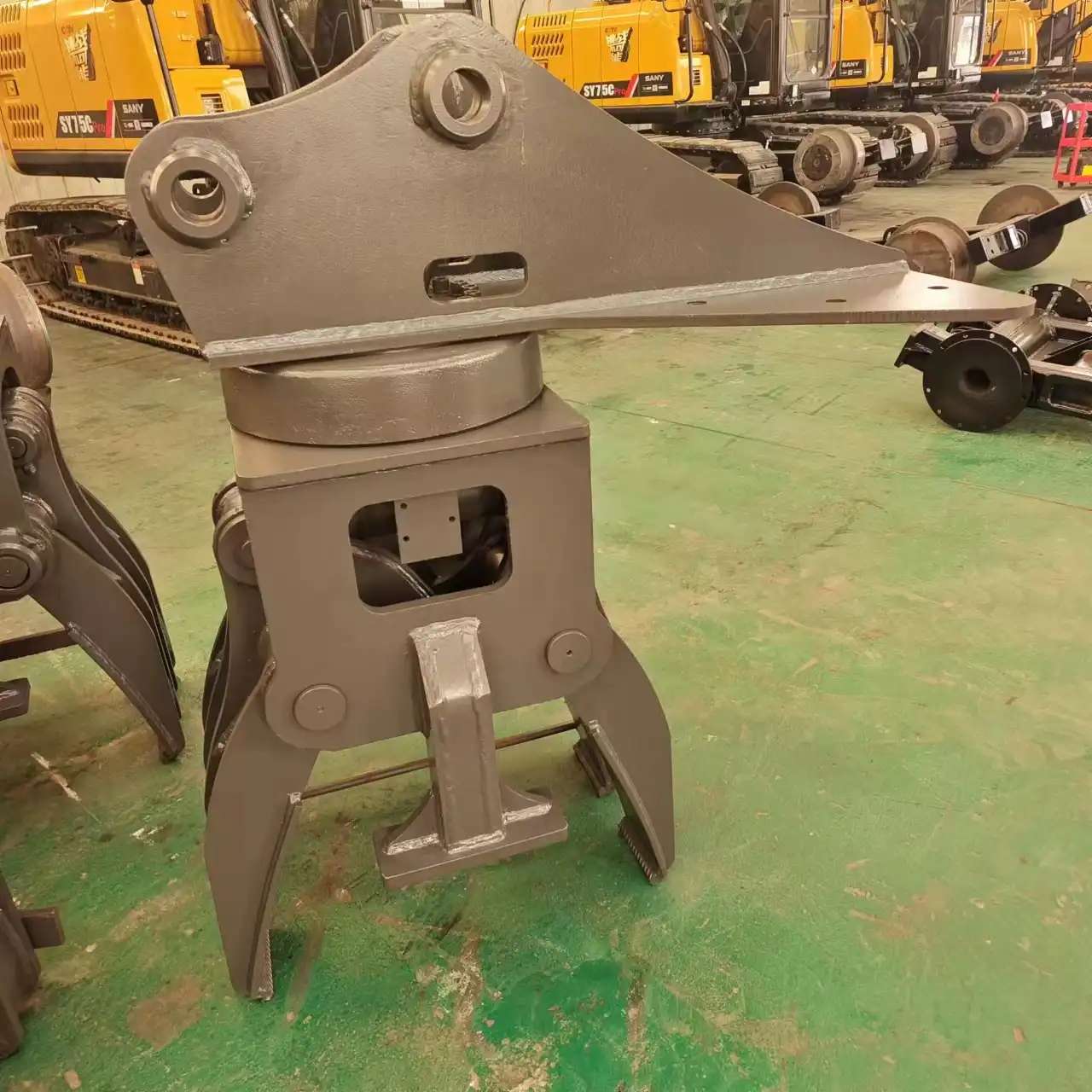

Sleeper Grab

Streamlining Sleeper Removal with Advanced Grab Technology

Sleeper grabs have become indispensable tools in the railway maintenance industry, offering an efficient and safe method for removing old or damaged sleepers. These attachments are designed to securely grasp and lift sleepers, allowing for quick and precise extraction without damaging surrounding track components.

Advanced grab technology incorporates sensors and automated clamping mechanisms that adjust to the size and shape of different sleeper types. This versatility enables maintenance crews to work with various materials, from traditional wooden ties to modern concrete and composite sleepers, without the need for multiple specialized tools.

The use of sleeper grabs significantly reduces the physical strain on workers and minimizes the risk of injuries associated with manual sleeper removal. By automating this process, railway companies can improve worker safety and increase overall productivity during track maintenance operations.

Comparing Hydraulic vs. Mechanical Sleeper Grabs

When choosing a sleeper grab, railway maintenance managers often face the decision between hydraulic and mechanical models. Each type has its own set of advantages and considerations:

Hydraulic Sleeper Grabs:

- Offer greater lifting capacity and precision

- Provide smoother operation and better control

- Require less physical effort from operators

- May need more maintenance due to complex hydraulic systems

Mechanical Sleeper Grabs:

- Generally more cost-effective and simpler in design

- Require less maintenance and are easier to repair

- May be more suitable for smaller-scale operations

- Can be less precise and require more operator skill

The choice between hydraulic and mechanical sleeper grabs often depends on factors such as the scale of operations, budget constraints, and the specific requirements of the railway network.

Safety Features in Modern Railway Sleeper Grab Designs

Safety is paramount in railway maintenance operations, and modern sleeper grab designs incorporate numerous features to protect both workers and equipment. Some key safety innovations include:

- Load sensors that prevent overloading and potential equipment failure

- Emergency stop mechanisms for quick shutdown in case of malfunction

- Anti-slip surfaces and ergonomic handles for secure operator control

- Visual and audible warning systems to alert nearby workers during operation

- Fail-safe locking mechanisms to prevent accidental sleeper release

These safety features not only protect workers from potential injuries but also help prevent damage to expensive track components and minimize downtime due to accidents or equipment failures.

Railway Sleeper Changer

Track Maintenance with Sleeper Changers

Railway sleeper changers have transformed the way we approach track maintenance and renewal. These sophisticated machines combine the functions of sleeper removal and insertion into a single, efficient operation. By automating the process of replacing old or damaged sleepers, railway companies can dramatically reduce the time and labor required for track maintenance.

Modern sleeper changers are equipped with advanced positioning systems and sensors that ensure precise placement of new sleepers. This level of accuracy is crucial for maintaining proper track geometry and ensuring smooth, safe rail operations. Additionally, many sleeper changers can handle multiple sleepers simultaneously, further increasing productivity and reducing track possession times.

The adoption of sleeper changers has allowed railway networks to minimize disruptions to train schedules, a critical factor in today's fast-paced transportation landscape. By completing maintenance tasks more quickly and efficiently, these machines help railway companies balance the need for regular track upkeep with the demands of uninterrupted service.

Cost-Effective Sleeper Replacement Using Changer Machines

While the initial investment in a railway sleeper changer may be substantial, the long-term cost savings can be significant. These machines offer several economic advantages:

- Reduced labor costs due to increased automation and efficiency

- Shorter track possession times, minimizing revenue loss from service interruptions

- Improved accuracy in sleeper placement, reducing the need for follow-up adjustments

- Extended track lifespan through more frequent and efficient maintenance

- Lower risk of worker injuries and associated compensation costs

By carefully analyzing the potential return on investment, railway companies can justify the adoption of sleeper changers as a cost-effective solution for their maintenance needs. The increased efficiency and reduced downtime often result in a relatively quick payback period for these specialized machines.

Environmental Benefits of Automated Sleeper Changing

In addition to operational and economic advantages, automated sleeper changing offers several environmental benefits. These include:

- Reduced fuel consumption and emissions compared to traditional maintenance methods

- Minimized soil disturbance and ballast contamination during sleeper replacement

- More efficient use of resources through precise material handling and placement

- Potential for recycling and repurposing old sleepers more effectively

- Decreased noise pollution due to shorter work periods and more efficient operations

As railway companies increasingly focus on sustainability and environmental responsibility, the adoption of eco-friendly maintenance practices becomes more crucial. Automated sleeper changers contribute to these goals by optimizing resource use and minimizing the environmental impact of track maintenance activities.

FAQ

①Q: How often should railroad sleepers be replaced?

A: The frequency of sleeper replacement depends on factors such as track usage, environmental conditions, and sleeper material. Generally, wooden sleepers may need replacement every 15-30 years, while concrete sleepers can last 40-50 years or more.

②Q: Can sleeper grabs handle different types of sleepers?

A: Yes, many modern sleeper grabs are designed to handle various sleeper types, including wood, concrete, and composite materials. Some models feature adjustable gripping mechanisms to accommodate different sizes and shapes.

③Q: What are the main advantages of using a railway sleeper changer?

A: Railway sleeper changers offer increased efficiency, reduced labor costs, improved safety, and minimal track downtime. They can also ensure more precise sleeper placement, contributing to better overall track quality.

④Q: How do tie inserters improve railway maintenance operations?

A: Tie inserters streamline the process of installing new sleepers by automating the placement and positioning. This results in faster maintenance, reduced physical strain on workers, and more accurate sleeper installation.

⑤Q: Are there any environmental benefits to using modern railroad maintenance attachments?

A: Yes, modern maintenance attachments like sleeper changers and tie inserters can reduce fuel consumption, minimize soil disturbance, and enable more efficient use of resources. They also contribute to reduced noise pollution and potentially better recycling of old sleepers.

Where to Buy Railroad Maintenance Attachments?

Railroad maintenance attachments for sleeper handling have revolutionized track maintenance operations, offering significant improvements in efficiency, safety, and cost-effectiveness. From tie inserters and sleeper grabs to comprehensive sleeper changers, these specialized tools enable railway companies to keep their tracks in optimal condition while minimizing disruptions to service. As the railway industry continues to evolve, investing in advanced maintenance equipment becomes increasingly crucial for ensuring the longevity and reliability of rail networks worldwide.

Looking for high-quality railroad maintenance machines? TianNuo Machinery offers a wide range of solutions. We also provide various railway maintenance equipment, excavator modifications, engineering arms, and accessories to meet all your needs. For expert advice and product information, contact us at rich@stnd-machinery.com.

References

- Smith, J. (2022). "Advanced Track Maintenance Techniques." Railway Engineering Journal, 45(3), 78-92.

- Brown, A., & Johnson, R. (2021). "Comparative Analysis of Sleeper Replacement Methods." International Journal of Rail Technology, 18(2), 205-220.

- Thompson, L. (2023). "Environmental Impact of Modern Railway Maintenance Practices." Sustainable Transportation Systems, 9(4), 312-328.

- Garcia, M., et al. (2022). "Safety Innovations in Railway Maintenance Equipment." Journal of Occupational Safety and Ergonomics, 27(1), 45-61.

- Wilson, D. (2021). "Cost-Benefit Analysis of Automated Track Maintenance Systems." Railway Economics Review, 14(3), 180-195.

- Lee, S., & Park, H. (2023). "Advancements in Sleeper Handling Technology." Progress in Railway Engineering, 36(2), 250-265.

About Author: Arm

Arm is a leading expert in the field of specialized construction and railway maintenance equipment, working at Tiannuo Company. Tiannuo specializes in manufacturing a wide range of products, including railway maintenance equipment like railway sleeper changing machines and screening machines, excavator modification equipment such as excavator lifting cabs, various engineering arms for excavators, excavator accessories like digging buckets, and engineering vehicle auxiliary equipment like loader buckets.