The Perfect Scoop: How the Shell Bucket is Redefining Excavation Efficiency

In the rugged world of excavation, where brute force meets precision, every component matters. The difference between profit and loss, between a project completed on schedule and one plagued by delays, often rests on the tool that makes first contact with the earth: the bucket. For decades, excavator operators have faced a relentless tug-of-war—choosing between the raw, scooping power of a standard bucket and the clean, sifting capability of a skeleton bucket.

Today, that compromise is rendered obsolete. Enter a new paradigm in attachment engineering: the Shell Bucket. This isn't merely an accessory; it's a revolutionary re-imagination of the excavator's primary interface, designed to master the most challenging, heterogeneous materials with unparalleled grace and speed.

The Problem in the Pile: Separation Anxiety

Imagine a typical demolition site or material handling yard. A mountain of debris isn't just rubble—it's a chaotic mix. Crushed concrete interlaces with precious, reusable topsoil. Demolition wood tangles with scrap metal. Valuable aggregate is buried within a matrix of waste. The traditional approach is a two-step, time-and-fuel-intensive headache: first, a standard bucket clumsily scoops everything, then the load must be dumped for slow, manual separation or run through a screener.

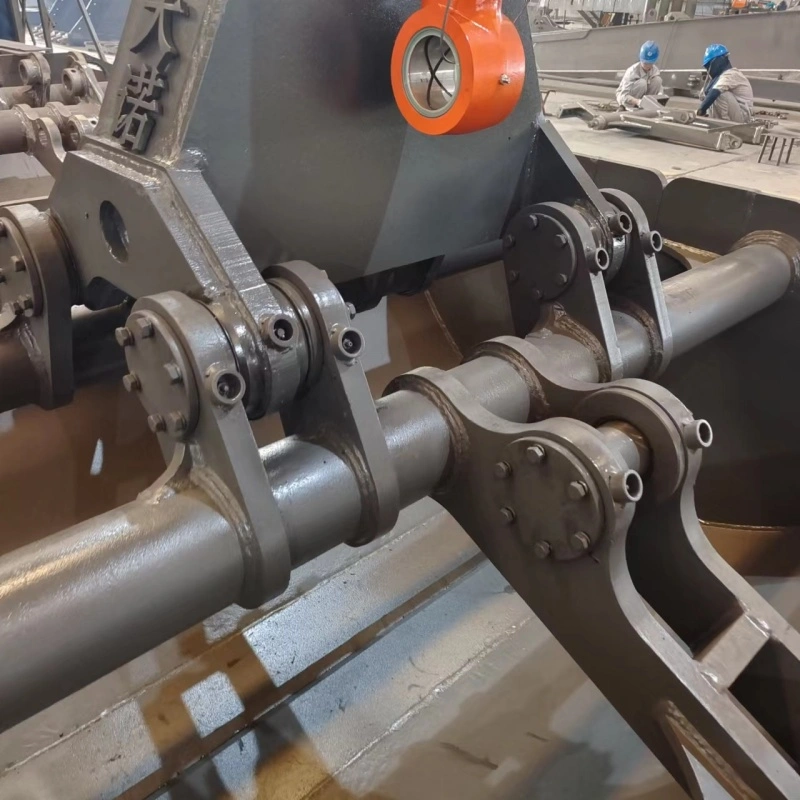

The Shell Bucket eliminates this costly inefficiency at its source. Its design is an exercise in intelligent filtration. Inspired by the structural efficiency found in nature, its profile features strategically spaced, reinforced tines or a perforated shell-like structure. As the bucket drives into a mixed pile, the magic happens during the dig. Loose soil, sand, and fine gravel flow seamlessly through the openings, sifted and ready for immediate reuse or backfilling. Meanwhile, larger, valuable materials—rocks, bricks, concrete chunks, debris—are captured and retained within the bucket's embrace.

Engineering Excellence: More Than Just Holes

The genius of the Shell Bucket lies not just in what it removes, but in what it provides:

Unmatched Versatility: It is the ultimate multi-tool for sites dealing with contaminated soil, demolition waste, compost turning, riverbed gravel extraction, and landscape cleanup. One attachment replaces two or three, slashing capital expenditure on machinery.

Dramatic Cycle Time Reduction: By combining digging and screening into one fluid motion, operators achieve clean fill and sorted material in a single pass. Fewer cycles mean lower fuel consumption, reduced machine wear, and a dramatically faster project timeline.

Preservation of Value: For recyclers and operators, the Shell Bucket is a revenue protector. It allows for the on-site separation and recovery of valuable materials that would otherwise be lost to landfill costs or require expensive secondary processing.

Operator Confidence & Precision: The bucket provides exceptional visibility into the work area, allowing for precise grading and contouring with clean material. It turns the complex task of selective material handling into an intuitive process.

The Ripple Effect: Efficiency Across the Job Site

The impact of the Shell Bucket extends far beyond the end of the dipper stick. By delivering clean, screened material directly where it's needed, it:

Eliminates Double-Handling: No more separate stockpiling, loading, and screening steps.

Reduces Site Congestion: Less auxiliary equipment (screeners, additional haul trucks) is needed on-site, enhancing safety and logistics.

Lowers Environmental Footprint: By maximizing material reuse on-site and minimizing transportation and processing, it contributes directly to more sustainable construction practices.

Built for the Fight: Durability Meets Design

Forged from high-tensile, abrasion-resistant steel and featuring reinforced edges and strategic wear protection, the Shell Bucket is engineered for longevity. Its robust construction ensures it withstands the punishing demands of sorting heavy demolition debris while its intelligent design prevents clogging and maintains its sifting efficiency throughout its long service life.

In an industry where time is literally money, and efficiency is the ultimate competitive edge, the right tool changes everything. The Shell Bucket is not an incremental improvement; it is a fundamental shift. It transforms the excavator from a simple earthmover into a sophisticated, on-the-fly material classification system.

Stop digging your problems. Start sorting your solutions. The Shell Bucket turns mixed material from a costly challenge into a streamlined opportunity. It’s the clear choice for the modern operator who values precision, profit, and performance.

Upgrade your dig. Define your efficiency. Specify the Shell Bucket.