What are common uses of railway excavator dustpan bucket?

The railway excavator dustpan bucket serves as an indispensable attachment for modern rail infrastructure maintenance and construction operations. This specialized equipment combines the efficiency of traditional excavator functionality with railway-specific design features, enabling operators to tackle demanding tasks along railway corridors. Railway maintenance professionals rely heavily on these versatile tools for various applications ranging from routine track cleaning to extensive ballast replacement projects. The dustpan bucket's unique design allows for efficient material handling while maintaining the precise control needed for sensitive railway environments.

Railway Track Cleaning and Debris Removal

Vegetation and Organic Matter Clearance

Railway corridors constantly battle against nature's persistent growth, making vegetation management a critical ongoing concern for track operators. The railway excavator dustpan bucket excels at removing overgrown brush, fallen trees, and accumulated organic debris that can compromise track safety and operational efficiency. Railway maintenance teams use these attachments to move trees, brush, logs, mud, boulders, and rock while improving overall drainage alongside the railway track. The wide opening and robust construction allow operators to gather substantial amounts of vegetation in a single pass, dramatically reducing the time required for corridor maintenance.

Seasonal debris presents unique challenges throughout the year, from autumn leaf accumulation to storm-damaged vegetation. The dustpan bucket's design accommodates these varying conditions by providing excellent material retention while allowing for efficient dumping at designated disposal areas. Professional maintenance crews appreciate how these attachments can navigate tight spaces between tracks and infrastructure while maintaining the clearance needed for safe railway operations.

Foreign Object and Waste Material Removal

Railway environments frequently accumulate foreign objects ranging from construction materials to unauthorized dumping. The dustpan bucket's versatility shines when collecting mixed debris types, from small scattered items to larger discarded materials. Its reinforced construction handles sharp objects and heavy materials without compromising structural integrity, ensuring reliable performance during intensive cleanup operations.

Emergency response situations often require rapid debris clearance following accidents or severe weather events. The railway excavator dustpan bucket enables quick mobilization of cleanup efforts, allowing teams to restore track accessibility efficiently. The attachment's ability to work in confined spaces makes it particularly valuable for incident response where traditional cleanup methods might prove inadequate or unsafe.

Drainage System Maintenance

Proper drainage remains fundamental to railway infrastructure longevity, preventing water accumulation that can undermine track stability. Railway excavator dustpan buckets facilitate comprehensive ditch cleaning and culvert maintenance by efficiently removing accumulated sediment, debris, and vegetation that impede water flow. The attachment's wide profile and controlled dumping capabilities make it ideal for creating and maintaining proper drainage gradients along railway corridors.

Routine drainage maintenance prevents costly infrastructure damage while ensuring regulatory compliance with environmental and safety standards. The dustpan bucket's precision control allows operators to work near sensitive areas without disturbing adjacent infrastructure, making it an essential tool for maintaining the delicate balance between effective drainage and infrastructure protection.

Ballast Bed Maintenance and Replacement

Contaminated Ballast Removal

Ballast degradation represents one of the most significant ongoing challenges in railway maintenance, requiring systematic removal and replacement to maintain track stability. Over time, ballast becomes worn and loses its angularity, becoming rounded, necessitating regular cleaning and replacement operations. The railway excavator dustpan bucket provides an efficient solution for removing contaminated ballast material, allowing maintenance teams to address fouled sections before they compromise track integrity.

The attachment's design accommodates the unique challenges of ballast handling, from the varied sizes of aggregate materials to the need for precise placement during replacement operations. Professional maintenance crews rely on these tools to extract contaminated materials while minimizing disruption to adjacent track sections. The controlled removal process ensures that only necessary materials are disturbed, reducing waste and improving project efficiency.

Fresh Ballast Distribution and Placement

Distributing fresh ballast requires precision and control to achieve proper track geometry and stability. Railway excavator dustpan buckets excel at transporting and placing ballast materials with the accuracy needed for professional track construction. The attachment's wide opening facilitates rapid loading from supply sources, while its controlled dumping mechanism allows for precise placement along track sections.

Quality ballast placement directly impacts track performance and longevity, making proper equipment selection crucial for successful projects. The dustpan bucket's ability to handle varying material types and quantities makes it adaptable to different project requirements, from small maintenance operations to large-scale reconstruction efforts. Experienced operators appreciate how these attachments maintain material integrity during transport and placement operations.

Shoulder Ballast Management

Shoulder ballast cleaning consists of removing ballast at the end of the ties, screening the ballast and discarding fines and fouling material and restoring the good ballast to the shoulder. The railway excavator dustpan bucket plays a crucial role in this process by efficiently collecting and relocating ballast materials during shoulder maintenance operations. Its wide profile and controlled operation make it ideal for working in the confined spaces typical of shoulder areas.

Proper shoulder maintenance ensures adequate track drainage while providing stability for the overall track structure. The dustpan bucket's versatility allows operators to perform both removal and placement operations with the same attachment, streamlining workflow and reducing equipment requirements. This efficiency translates to reduced project costs and improved scheduling flexibility for maintenance operations.

Material Handling in Railway Construction

Construction Material Transport

Railway construction projects involve substantial material handling requirements, from transporting concrete components to moving specialized track materials. The railway excavator dustpan bucket serves as a versatile tool for these demanding applications, offering the capacity and control needed for efficient material movement. Its robust construction handles heavy loads while providing the precision required for accurate placement in construction environments.

Project efficiency often depends on effective material handling capabilities, making equipment selection critical for successful outcomes. The dustpan bucket's ability to adapt to different material types and handling requirements makes it valuable for diverse construction applications. Professional construction teams appreciate how these attachments maintain productivity while ensuring safe handling of valuable materials.

Excavation and Earthwork Operations

Railway construction frequently involves extensive earthwork operations, from creating level building pads to establishing proper drainage profiles. The railway excavator dustpan bucket provides excellent performance for these applications, combining efficient material removal with precise dumping capabilities. Its wide profile maximizes productivity during bulk excavation while maintaining the control needed for finish work.

Complex railway projects often require varied excavation approaches, from rough excavation to precision grading. The dustpan bucket's versatility accommodates these changing requirements without necessitating equipment changes, improving project efficiency and reducing mobilization costs. Experienced operators value how these attachments maintain consistent performance across different soil conditions and project phases.

Site Preparation and Cleanup

Effective site preparation establishes the foundation for successful railway construction projects, requiring thorough cleanup and material organization. Railway excavator dustpan buckets excel at these preparatory tasks, efficiently collecting and relocating debris while preparing sites for construction activities. The attachment's design accommodates mixed material types commonly encountered during site preparation.

Post-construction cleanup requires similar versatility and efficiency, making the dustpan bucket valuable throughout project lifecycles. Its ability to handle both fine and coarse materials ensures comprehensive cleanup capabilities, supporting project completion and regulatory compliance. Professional construction teams rely on these attachments to maintain clean, organized work environments that enhance safety and productivity.

FAQ

①What makes railway excavator dustpan buckets different from standard excavator buckets?

Railway excavator dustpan buckets feature specialized design elements including reinforced construction, wider openings for efficient material collection, and enhanced dumping control mechanisms. These modifications optimize performance for railway-specific applications while maintaining durability under demanding operating conditions.

②How do I determine the right size dustpan bucket for my railway maintenance operations?

Bucket sizing depends on your excavator's capacity, typical material types, and operational requirements. Consider factors like track clearances, material density, and project scope when selecting appropriate dimensions. Professional consultation can help optimize selection for specific applications.

③What maintenance requirements should I expect for railway excavator dustpan buckets?

Regular maintenance includes inspection of cutting edges, structural components, and attachment points. Proper lubrication and prompt repair of wear items ensures optimal performance and extends service life. Following manufacturer guidelines prevents premature failure and maintains safety standards.

④Can railway excavator dustpan buckets handle different types of ballast materials?

Quality dustpan buckets accommodate various ballast types including granite, limestone, and recycled materials. The robust construction and appropriate sizing handle different aggregate sizes and densities effectively, making them suitable for diverse railway maintenance applications.

⑤What safety considerations apply when using railway excavator dustpan buckets near active tracks?

Safety protocols include maintaining proper clearances from live tracks, coordinating with railway dispatch, and ensuring adequate operator training. Proper flagging procedures and communication systems prevent conflicts with train operations while maintaining productive work environments.

Railway excavator dustpan buckets represent essential equipment for modern rail infrastructure maintenance and construction operations. Their versatility across track cleaning, ballast maintenance, and material handling applications makes them invaluable investments for railway contractors and maintenance organizations. Understanding these diverse applications enables better equipment selection and improved operational efficiency across railway projects.

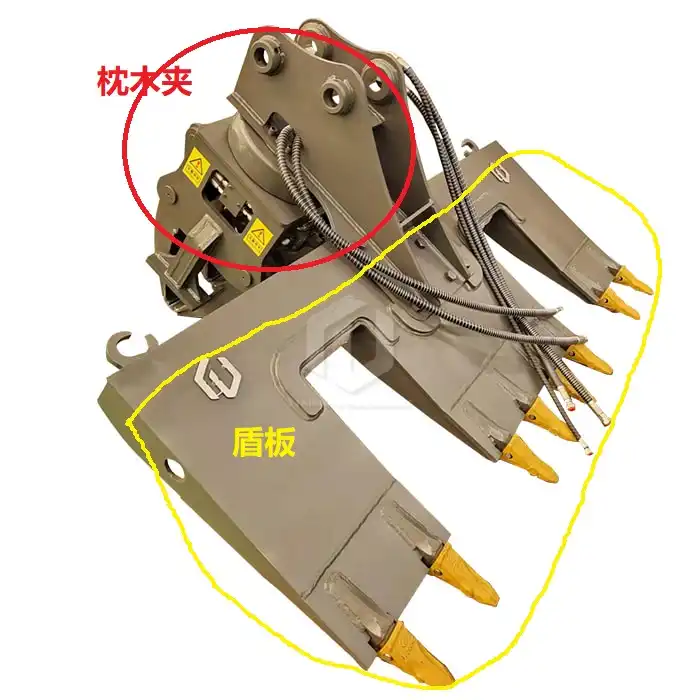

Tiannuo Machinery specializes in manufacturing high-quality railway excavator dustpan buckets designed for demanding railway applications. Our dustpan buckets feature a width of 3400mm, height of 400mm, and 320mm openings on both sides, constructed from high-strength alloy plate for maximum durability and performance. These specifications ensure optimal material handling capacity while maintaining the structural integrity needed for intensive railway maintenance operations.

For more information about our comprehensive range of railway maintenance equipment and excavator attachments, please contact us at rich@stnd-machinery.com. Our experienced team can provide detailed specifications and application guidance to help you select the optimal equipment for your specific railway maintenance requirements.

References

- Railway Track Engineering Handbook: Ballast Maintenance and Track Geometry Standards for Modern Rail Systems, International Railway Engineering Association, 2023.

- Heavy Equipment Applications in Railway Construction: Excavator Attachments and Specialized Tools, Construction Equipment Research Institute, 2024.

- Railway Infrastructure Maintenance: Best Practices for Track Cleaning and Debris Management, Rail Maintenance Professional Journal, 2024.

- Ballast Management Systems: Modern Approaches to Railway Track Foundation Maintenance, Railway Engineering Quarterly, 2023.

- Construction Equipment Selection for Railway Projects: Optimizing Efficiency and Safety in Rail Construction, Heavy Equipment Management Review, 2024.

About Author: Arm

Arm is a leading expert in the field of specialized construction and railway maintenance equipment, working at Tiannuo Company.