What are the different types of excavator root rippers available?

When tackling tough excavation projects involving root removal, forestry clearing, or demolition work, selecting the right attachment can make all the difference between a smooth operation and a frustrating struggle. Excavator root rippers represent specialized tools designed to handle the demanding task of breaking through stubborn root systems, rocky terrain, and compacted soil with remarkable efficiency.

These powerful attachments transform standard excavators into versatile machines capable of penetrating even the most challenging underground obstacles. The market offers three primary categories of root rippers, each engineered to excel in specific working conditions and applications. Understanding these variations helps operators choose the most suitable equipment for their particular needs, whether dealing with dense forest clearance, urban demolition projects, or agricultural land preparation.

Beyond basic root removal, modern excavator gripper technology has evolved to incorporate advanced hydraulic systems and specialized tooth configurations that maximize productivity while minimizing operator fatigue. The choice between single-tooth precision tools, multi-tooth rake systems, and hydraulic-powered variants depends largely on soil conditions, project scope, and operational requirements that vary significantly across different industries and applications.

Single-Tooth Root Ripper

The single-tooth excavator root ripper stands as the most straightforward yet remarkably effective solution for precision excavation tasks. This attachment features a robust, pointed steel tooth that concentrates tremendous force into a narrow contact area, allowing operators to penetrate deeply into compacted soil and break through individual root systems with surgical precision.

Design Characteristics and Construction

Single-tooth rippers typically incorporate high-strength steel construction with reinforced mounting brackets that distribute stress evenly across the excavator's arm assembly. The tooth itself features a tapered design that minimizes soil displacement while maximizing penetration depth, making it particularly effective in confined spaces where precision matters more than coverage area.

The attachment's streamlined profile reduces drag resistance, allowing operators to work more efficiently in dense clay soils or areas with extensive root networks. Many models include replaceable tooth tips manufactured from hardened steel alloys that maintain sharpness even after extended use in abrasive conditions.

Operational Advantages

Operators appreciate the single-tooth design for its exceptional maneuverability and control precision. The concentrated force application allows for targeted root severing without disturbing surrounding soil structure, making it ideal for selective clearing operations or working around existing infrastructure.

The reduced weight compared to multi-tooth alternatives means less strain on the excavator's hydraulic system and improved fuel efficiency during extended operations. This makes single-tooth rippers particularly valuable for smaller excavators or projects where operational costs must be carefully managed.

Application Scenarios

Single-tooth excavator root rippers excel in urban landscaping projects where precision is paramount. They prove invaluable for removing individual tree stumps, breaking through sidewalk root intrusions, or preparing planting beds without disturbing adjacent vegetation. Construction sites benefit from their ability to address specific problem areas without over-excavating valuable topsoil.

Agricultural applications include breaking up hardpan layers, creating drainage channels, and preparing fields for new plantings. The precision offered by single-tooth designs allows farmers to address compaction issues without disturbing the overall soil profile, maintaining important microbial ecosystems that support crop productivity.

Multi-Tooth/Rake Root Ripper

Multi-tooth excavator root rippers represent the workhorses of large-scale clearing operations, featuring multiple parallel teeth arranged in a rake-like configuration. This design philosophy emphasizes coverage area and material handling capacity over the precision offered by single-tooth alternatives, making them indispensable for extensive land clearing projects.

Configuration Options and Specifications

Most multi-tooth rippers feature between three to seven individual teeth, with spacing optimized to prevent clogging while maintaining effective ground contact. The teeth can be straight or curved, depending on the intended application, with curved designs providing better material retention for debris removal operations.

Advanced models incorporate adjustable tooth spacing systems that allow operators to customize the attachment for specific soil conditions or debris types. Some manufacturers offer interchangeable tooth profiles, enabling the same base unit to handle everything from fine root networks to large woody debris with equal effectiveness.

Productivity Benefits

The parallel tooth arrangement allows operators to cover significantly more ground area per pass compared to single-tooth alternatives. This translates directly into reduced project completion times and lower labor costs, particularly important for large-scale forestry operations or extensive demolition projects.

Multi-tooth designs also excel at gathering and organizing debris during the ripping process. The rake-like action naturally collects broken roots, rocks, and other materials, reducing the need for separate cleanup operations and streamlining the overall workflow.

Industry Applications

Forestry operations rely heavily on multi-tooth excavator rippers for site preparation following timber harvesting. The ability to simultaneously break up root systems and gather slash materials makes these attachments essential for preparing sites for replanting or converting forest land to agricultural use.

Mining and quarrying operations utilize multi-tooth rippers for overburden removal and site preparation. The robust construction required to handle rocky conditions makes these attachments suitable for the demanding environments encountered in extractive industries, where equipment reliability directly impacts operational profitability.

Hydraulic/Powered Root Ripper

Hydraulic-powered excavator root rippers represent the pinnacle of excavation attachment technology, incorporating active hydraulic systems that enhance the natural digging force of the excavator. These sophisticated tools combine the benefits of traditional rippers with additional powered functionality that dramatically improves performance in challenging conditions.

Advanced Hydraulic Systems

Modern hydraulic root rippers feature independent hydraulic circuits that power rotating or oscillating mechanisms within the attachment itself. This additional movement capability allows the ripper to work more effectively in compacted soils by creating multiple force vectors that break up resistant materials more efficiently than static designs.

The hydraulic system typically connects to the excavator's auxiliary hydraulic outlets, requiring minimal modification to existing equipment. Advanced models include pressure relief valves and flow control systems that protect both the attachment and the host excavator from damage due to excessive loads or unexpected obstacles.

Performance Enhancements

The powered functionality significantly reduces the physical demands placed on the excavator's main hydraulic system. By distributing the work load between the excavator's arm movement and the attachment's internal mechanisms, operators can maintain consistent productivity even in extremely challenging conditions that would overwhelm static alternatives.

Vibration-dampening systems integrated into many hydraulic models reduce operator fatigue and improve precision control. This becomes particularly important during extended operations where operator comfort directly impacts both productivity and safety outcomes.

Specialized Applications

Hydraulic root rippers prove invaluable in urban environments where noise restrictions limit operational windows. The enhanced efficiency allows operators to complete tasks more quickly, reducing the impact on surrounding communities while maintaining high productivity standards.

Specialized applications include pipeline installation, where the combination of precision and power allows operators to create exact trenches through root-laden soil without damaging existing underground infrastructure. The controlled force application makes these attachments particularly suitable for working near sensitive utilities or structures.

FAQ

①What factors should I consider when choosing an excavator root ripper?

Consider your excavator's size and hydraulic capacity, the typical soil conditions you encounter, project scale, and whether you need precision work or high-volume clearing. Match the ripper's weight and power requirements to your machine's specifications for optimal performance.

②Can different ripper types be used interchangeably on the same excavator?

Yes, most excavators can accommodate different ripper types using quick-connect coupling systems. However, ensure the attachment's weight and hydraulic requirements match your excavator's specifications to prevent performance issues or equipment damage.

③How do I maintain my excavator gripper for optimal performance?

Regular maintenance includes checking all fasteners for tightness, lubricating pivot points, inspecting teeth for wear, and ensuring hydraulic connections remain secure. Replace worn components promptly to maintain efficiency and prevent costly repairs.

④What industries benefit most from hydraulic root rippers?

Construction, forestry, mining, demolition, and agricultural industries all benefit from hydraulic root rippers. The enhanced power and precision make them particularly valuable for challenging projects where traditional static attachments would be insufficient.

Choose Tiannuo for Superior Excavator Root Ripper Solutions

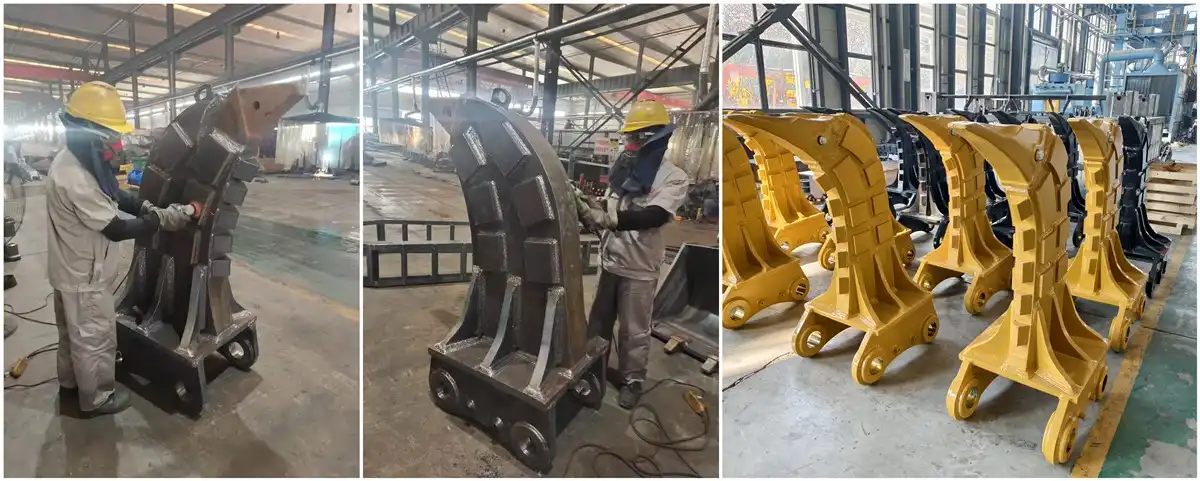

Tiannuo's excavator gripper attachments feature high-strength steel clamp bodies, adjustable clamp teeth, and precision-engineered oil cylinders that deliver reliable performance across diverse applications. Our hydraulic systems provide smooth operation through optimized pressure oil distribution, while robust pipeline connections ensure long-term reliability.

Whether you're tackling excavation projects, demolition work, ore extraction, or slope cleaning operations, Tiannuo's comprehensive range of attachments delivers the durability and performance your projects demand. Regular maintenance protocols ensure extended service life and consistent productivity.

Ready to enhance your excavation capabilities with professional-grade root rippers? Contact our technical specialists today to discuss your specific requirements and discover how Tiannuo's innovative solutions can transform your operational efficiency.

For detailed product specifications and expert consultation, reach out to us at rich@stnd-machinery.com. Our team stands ready to help you select the perfect attachment for your unique operational needs.

References

- Construction Equipment Magazine: "Advanced Excavator Attachments for Modern Earthmoving Operations" (2024)

- Heavy Equipment Digest: "Hydraulic Root Ripper Technology and Applications in Construction" (2023)

- Forestry Machinery Journal: "Efficiency Improvements in Land Clearing Equipment Design" (2024)

- Mining Equipment Review: "Excavator Attachment Selection for Challenging Terrain" (2023)

- Agricultural Engineering Quarterly: "Soil Preparation Equipment for Modern Farming Operations" (2024)

About Author: Arm

Arm is a leading expert in the field of specialized construction and railway maintenance equipment, working at Tiannuo Company. Tiannuo specializes in manufacturing a wide range of products, including railway maintenance equipment like railway sleeper changing machines and screening machines, excavator modification equipment such as excavator lifting cabs, various engineering arms for excavators, excavator accessories like digging buckets, and engineering vehicle auxiliary equipment like loader buckets.