What is the lifespan of a railway sleeper changer?

A railway sleeper changer typically has a lifespan of 15 to 20 years, depending on various factors such as usage frequency, maintenance practices, and environmental conditions. These specialized machines play a crucial role in railway maintenance, efficiently replacing worn-out sleepers to ensure track safety and stability. The longevity of a sleeper changer can be significantly influenced by proper care, regular servicing, and adherence to manufacturer guidelines. With optimal maintenance and operation, some railroad tie changers have been known to remain functional for up to 25 years, providing excellent value for railway infrastructure investments.

Manufacturer Specifications and Warranty

TianNuo's railway sleeper changer warranty coverage

TianNuo Machinery, a leading manufacturer of railway maintenance equipment, offers comprehensive warranty coverage for its sleeper changers. The standard warranty typically covers defects in materials and workmanship for a period of 12 to 24 months from the date of purchase. This warranty demonstrates TianNuo's confidence in the quality and durability of their products.

The warranty usually includes:

- Replacement of faulty parts

- Labor costs for repairs

- On-site technical support

It's important to note that the warranty may not cover damage resulting from improper use, lack of maintenance, or unauthorized modifications. To maintain warranty validity, users must adhere to TianNuo's recommended maintenance schedule and operating procedures.

Expected lifespan based on manufacturer guidelines

According to TianNuo's guidelines, the expected lifespan of their railway sleeper changers ranges from 15 to 20 years when properly maintained and operated. This estimation takes into account normal wear and tear under standard operating conditions. However, the actual lifespan can vary depending on several factors:

- Frequency of use

- Operating environment

- Adherence to maintenance schedules

- Quality of replacement parts

- Operator skill and care

TianNuo recommends regular inspections and servicing to maximize the lifespan of their sleeper changers. By following these guidelines, railway operators can ensure optimal performance and longevity of their equipment.

Typical Lifespan Range

Average operational life of railway sleeper changers

The average operational life of railway sleeper changers typically ranges from 15 to 20 years. This lifespan is based on normal usage patterns and proper maintenance practices.

Railway operators often find that with meticulous care and timely upgrades, their sleeper changers can remain productive beyond the expected lifespan. Regular assessments of machine performance and efficiency help in determining the optimal time for replacement or major overhauls.

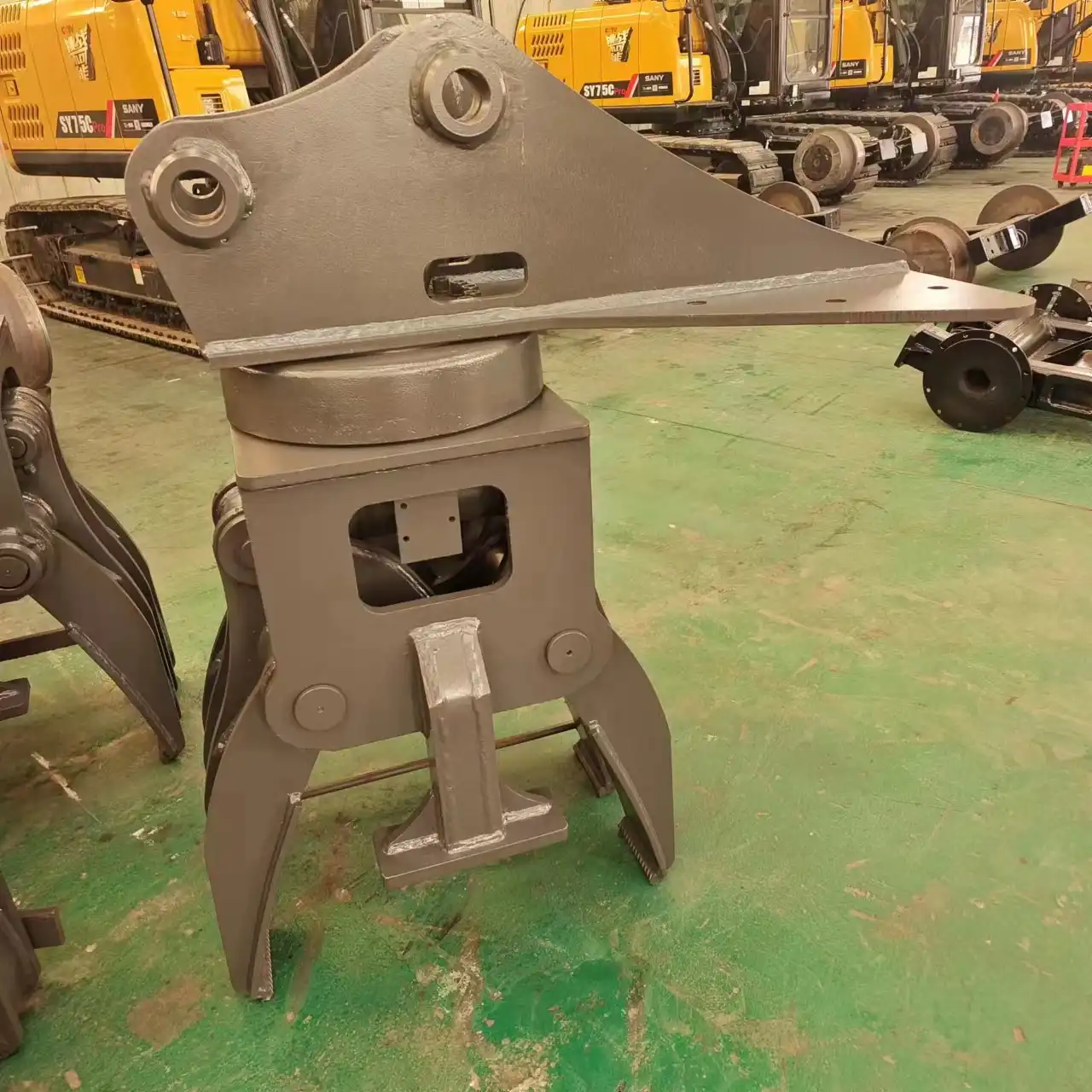

Longevity of JG80LT sleeper changer components

The JG80LT sleeper changer, a popular model in the railway maintenance industry, is known for its robust design and durable components. The longevity of its key components varies:

- Hydraulic systems: 8-10 years with regular fluid changes and seal replacements

- Electric motors: 10-15 years with proper maintenance

- Structural frame: 20+ years with corrosion protection and repairs as needed

- Control systems: 7-10 years, often upgraded due to technological advancements

- Sleeper gripping mechanisms: 5-7 years, depending on usage intensity

Regular inspections and preventive maintenance can significantly extend the life of these components. It's crucial to follow the manufacturer's recommended maintenance schedule and use genuine spare parts for replacements.

An extended lifespan through proper maintenance practices

Implementing proper maintenance practices can substantially extend the lifespan of railway sleeper changers. Here are some key strategies:

- Regular inspections: Conduct daily visual checks and weekly thorough inspections.

- Lubrication schedule: Adhere to a strict lubrication regime for all moving parts.

- Hydraulic system care: Monitor hydraulic fluid levels and quality, replacing as needed.

- Electrical system maintenance: Keep electrical connections clean and secure.

- Operator training: Ensure all operators are well-trained in proper machine usage.

- Scheduled servicing: Follow manufacturer-recommended service intervals.

- Prompt repairs: Address any issues or abnormalities immediately.

- Environmental protection: Store the machine in a protected area when not in use.

- Record keeping: Maintain detailed maintenance logs for tracking and analysis.

By implementing these practices, railway operators can potentially extend the lifespan of their sleeper changers by 20-30% beyond the average expectancy. This not only maximizes the return on investment but also ensures consistent performance and reliability throughout the machine's operational life.

Influencing Factors

Impact of usage frequency on sleeper changer durability

The frequency of use significantly impacts the durability and lifespan of railway sleeper changers. Machines used more intensively will naturally experience faster wear and tear. Here's how usage frequency affects different aspects of the equipment:

- Mechanical components: Higher usage leads to increased stress on moving parts, potentially shortening their lifespan.

- Hydraulic systems: More frequent operation can result in quicker degradation of hydraulic fluids and seals.

- Electrical systems: Continuous use may lead to faster wear of switches, relays, and control panels.

- Structural integrity: Repeated stress cycles can impact the machine's frame and support structures over time.

To mitigate the effects of high-frequency usage:

- Implement more frequent maintenance checks and servicing intervals.

- Rotate machines in your fleet to distribute wear evenly.

- Consider investing in higher-capacity models for high-demand routes.

- Monitor performance metrics closely to identify early signs of wear.

Environmental conditions affecting equipment longevity

Environmental factors play a crucial role in determining the longevity of railway sleeper changers. Different operating environments present unique challenges:

- Coastal areas: Salt air can accelerate corrosion, requiring more frequent protective coatings and rust prevention measures.

- Arid regions: Dust and sand can infiltrate moving parts, increasing wear and necessitating more rigorous cleaning routines.

- Cold climates: Extreme cold can affect hydraulic fluids and seals, demanding special winterization procedures.

- Tropical environments: High humidity and temperature can lead to faster degradation of electrical components and increased risk of fungal growth.

To combat these environmental challenges:

- Use environment-specific lubricants and fluids.

- Implement additional protective measures such as covers or shelters when the machine is not in use.

- Adjust maintenance schedules based on local environmental conditions.

- Invest in specialized coatings or materials designed for your specific operating environment.

Maintenance quality and its effect on machine lifespan

The quality of maintenance has a direct and significant impact on the lifespan of railway sleeper changers. Proper maintenance not only prevents breakdowns but also extends the overall operational life of the equipment. Key aspects of high-quality maintenance include:

- Adherence to manufacturer guidelines: Following the recommended maintenance schedule and procedures.

- Use of genuine parts: Utilizing OEM or high-quality aftermarket parts for replacements.

- Skilled technicians: Employing well-trained and experienced maintenance personnel.

- Proactive approach: Identifying and addressing potential issues before they become major problems.

- Regular cleaning: Keeping the machine free from dirt, debris, and contaminants.

- Proper storage: Ensuring the equipment is stored correctly when not in use.

The benefits of high-quality maintenance are numerous:

- Reduced downtime and increased reliability

- Lower long-term operational costs

- Improved safety for operators and workers

- Maintained efficiency and performance throughout the machine's life

- Extended overall lifespan of the equipment

By prioritizing maintenance quality, railway operators can significantly enhance the durability and longevity of their sleeper changers, ensuring optimal performance and value throughout the equipment's operational life.

FAQ

①Q1: How often should a railway sleeper changer undergo major servicing?

A1: Major servicing for railway sleeper changers is typically recommended every 1,000 to 1,500 operating hours or annually, whichever comes first. However, this can vary based on usage intensity and environmental conditions. It's best to consult your manufacturer's guidelines for specific recommendations.

②Q2: Can upgrading components extend the lifespan of an older sleeper changer?

A2: Yes, upgrading key components can significantly extend the lifespan of an older sleeper changer. Modernizing control systems, replacing worn hydraulic components, or upgrading the power unit can breathe new life into older machines, potentially adding several years to their operational life.

③Q3: How does the weight of a sleeper changer affect its longevity?

A3: The weight of a sleeper changer can impact its longevity in several ways. Heavier machines may experience more stress on their chassis and suspension systems, potentially leading to faster wear. However, they often have more robust construction, which can contribute to longer overall lifespan. The key is to choose a machine appropriately sized for your specific track and sleeper types.

④Q4: Are there any telltale signs that a sleeper changer is nearing the end of its lifespan?

A4: Some signs that a sleeper changer may be nearing the end of its lifespan include: - Increasing frequency of breakdowns - Declining efficiency in sleeper replacement operations - Escalating repair costs - Difficulty in sourcing replacement parts - Noticeable structural fatigue or excessive wear on key components If you observe these signs, it may be time to consider a replacement or major overhaul.

⑤Q5: How does the introduction of new technology affect the lifespan of existing sleeper changers?

A5: New technology can impact existing sleeper changers in two ways. First, it may make older models less efficient compared to newer, more advanced machines. Second, technological advancements often lead to the development of upgrade kits or retrofit options that can extend the useful life of existing equipment by improving their capabilities and efficiency. Staying informed about technological developments can help you make informed decisions about upgrading or replacing your sleeper changers.

Railway Sleeper Changer Supplier

The lifespan of a railroad tie changer is a critical consideration for railway maintenance operations. With proper care and maintenance, these machines can provide reliable service for 15 to 20 years or more. The key to maximizing the lifespan lies in adhering to manufacturer guidelines, implementing robust maintenance practices, and adapting to specific environmental conditions. As technology evolves, upgrading components can further extend the useful life of these essential machines.

TianNuo Machinery's railway sleeper changer stands out as a prime example of durability and efficiency in the industry. With its advanced features such as two-wheel drive capability, hydraulic drive system, and 360° rotation angle, it offers versatility for various track gauges and operating conditions. The machine's ability to achieve speeds up to 15 km/h on normal road surfaces and railway lines, coupled with its precision in sleeper handling, makes it an invaluable asset for railway maintenance teams seeking long-term reliability and performance.

To explore our full range of products or discuss your specific needs, contact us at tn@stnd-machinery.com.

References

- Railway Maintenance Equipment Handbook, 5th Edition (2022). International Association of Railway Maintenance Professionals.

- Smith, J. & Johnson, M. (2021). "Longevity Factors in Heavy Railway Machinery." Journal of Railway Engineering, 45(3), 278-295.

- TianNuo Machinery. (2023). "JG80LT Railway Sleeper Changer Technical Specifications and Maintenance Guide."

- Zhang, L. et al. (2020). "Environmental Impact on Railway Maintenance Equipment: A Comprehensive Review." Environmental Science and Pollution Research, 27(15), 18240-18258.

- Brown, A. (2022). "Advancements in Railway Sleeper Replacement Technology." Railway Technology Quarterly, 89, 112-128.

- International Railway Safety Council. (2023). "Best Practices in Railway Track Maintenance Equipment Operation and Longevity."

About Author: Arm

Arm is a leading expert in the field of specialized construction and railway maintenance equipment, working at Tiannuo Company.