What size bucket is an excavator?

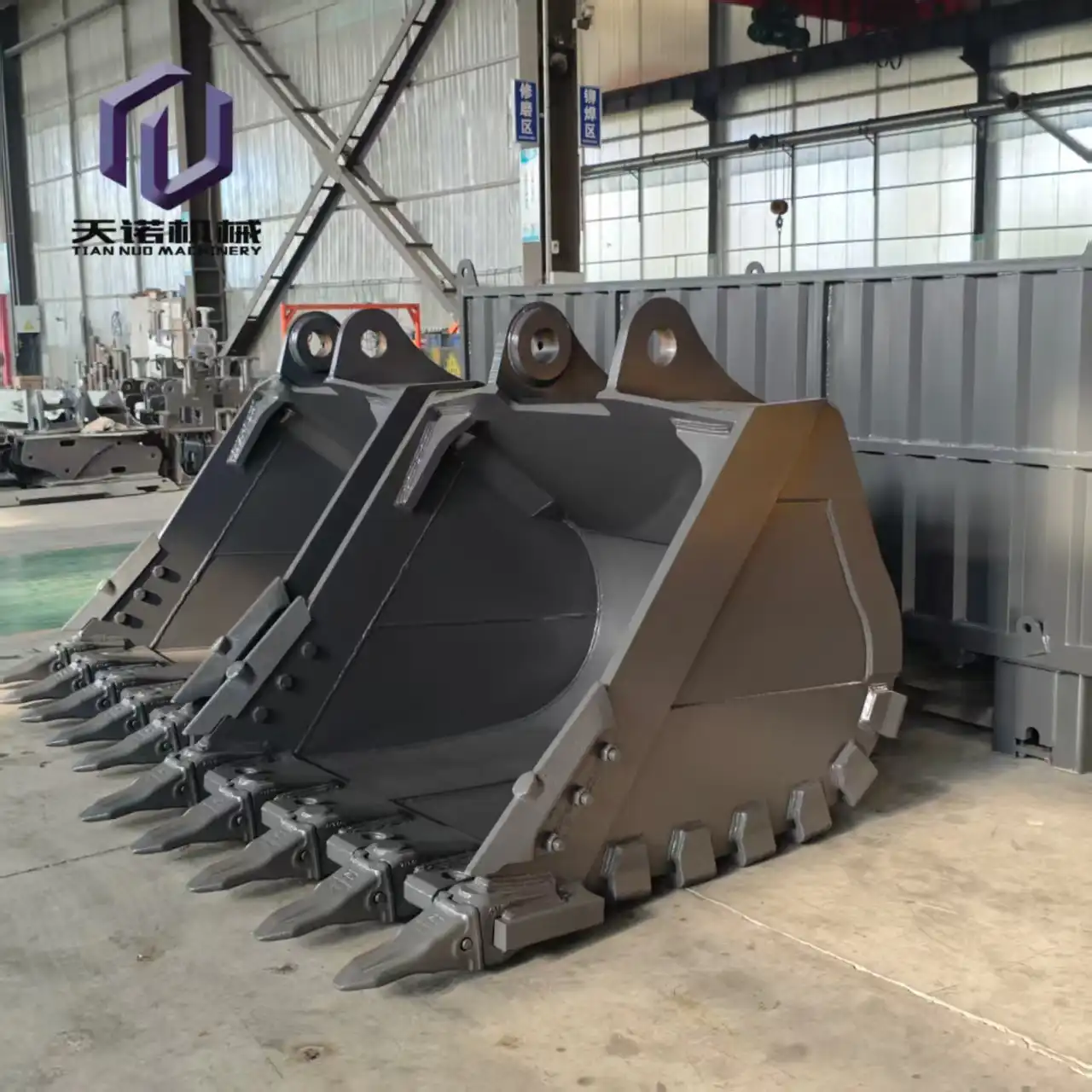

Selecting the right excavator bucket size is crucial for maximizing efficiency and productivity on any job site. Bucket size isn't one-size-fits-all; it varies significantly based on the excavator's weight, application requirements, and specific job demands. Typically, Buckets range from 0.1 to 5.0 cubic meters in capacity and 500 to 2000 mm in width, with smaller machines using compact buckets and larger excavators utilizing heavier, wider attachments. The appropriate bucket size directly impacts digging efficiency, fuel consumption, and overall project timelines. When choosing a bucket, consider not only the machine's specifications but also the material density you'll be handling, as this determines the optimal bucket capacity. Properly sized buckets prevent machine strain and ensure smooth operation, while undersized or oversized options can lead to inefficiency, increased wear, and potential safety issues. Professional manufacturers like Tiannuo offer customization options to match your specific excavator model and application needs, ensuring you get the perfect fit for maximum performance.

Excavator Weight (tons)

Excavator weight is the primary factor determining what size bucket your machine can effectively handle. The relationship between machine weight and bucket size is fundamental to proper excavator operation.

Weight Classifications

Mini excavators, typically weighing between 1-7 tons, generally use buckets with capacities ranging from 0.1 to 0.3 cubic meters. These compact machines are designed for precision work in confined spaces, making smaller buckets essential for maneuverability and balance.

Medium-sized excavators in the 8-25 ton range commonly utilize buckets between 0.4 and 1.2 cubic meters. These versatile machines balance power and mobility for general construction applications.

Heavy excavators exceeding 25 tons can accommodate significantly larger buckets, often ranging from 1.3 to 5.0 cubic meters. These powerful machines are engineered for intensive excavation projects where moving large volumes of material efficiently is paramount.

Weight-to-Capacity Correlation

The appropriate bucket capacity directly correlates with the excavator's weight class due to hydraulic limitations and stability considerations. Using an oversized bucket on a smaller machine creates dangerous instability and strains the hydraulic system beyond its design parameters.

Consider this practical correlation table for reference:

1-2 ton excavator: 0.1-0.12 cubic meter bucket

3-5 ton excavator: 0.15-0.25 cubic meter bucket

7-10 ton excavator: 0.3-0.5 cubic meter bucket

12-15 ton excavator: 0.6-0.8 cubic meter bucket

20-25 ton excavator: 0.9-1.2 cubic meter bucket

30-40 ton excavator: 1.5-2.5 cubic meter bucket

45+ ton excavator: 3.0-5.0 cubic meter bucket

Performance Impact Considerations

The relationship between excavator weight and bucket size significantly impacts operational performance. When properly matched, this combination optimizes fuel efficiency, cycle times, and overall productivity.

Using an undersized bucket relative to machine weight results in inefficient operation, as the excavator's power potential remains untapped. Conversely, an oversized bucket creates excessive strain, potentially leading to premature component failure, increased fuel consumption, and compromised safety.

For specialized applications, the weight-to-capacity ratio may need adjustment. For instance, when handling dense materials like rock or wet clay, operators often select buckets with 10-15% less capacity than what's recommended for standard soil excavation.

Standard Bucket Width (inches)

The width of an excavator bucket attachments plays a crucial role in operational efficiency and application suitability. Standard bucket widths range significantly across different machine sizes and applications.

Width Specifications by Machine Size

Compact excavators typically utilize buckets ranging from 12 to 24 inches (300-600 mm) in width. These narrower attachments enable precise digging in confined spaces and are ideal for utility trenching, landscaping, and residential applications.

Medium-sized excavators commonly employ buckets between 24 and 48 inches (600-1200 mm) wide. This range provides versatility for general construction tasks, offering a balance between material volume and maneuverability.

Large excavators often use buckets measuring 48 to 80 inches (1200-2000 mm) wide. These substantial attachments are designed for high-volume excavation in mining, large-scale earthmoving, and heavy construction projects.

Application-Specific Width Requirements

Different applications demand specific bucket widths for optimal performance:

For trenching applications, bucket width typically correlates with the required trench width. Utility installation projects often utilize buckets between 12-36 inches (300-900 mm) depending on pipe diameter and service specifications.

Foundation work generally requires wider buckets in the 30-60 inch (750-1500 mm) range to efficiently remove large volumes of soil while maintaining clean, square edges.

Drainage ditch creation benefits from specialized ditching buckets, which feature a distinctive trapezoidal design and widths ranging from 36-72 inches (900-1800 mm).

Width Selection Factors

Several factors should guide your bucket width selection:

Material density significantly impacts width selection. When handling lighter materials, wider buckets improve productivity without overburdening the machine. Conversely, dense materials may require narrower buckets to prevent exceeding the excavator's lifting capacity.

Ground conditions influence optimal width choice. Soft or unstable terrain often requires narrower buckets to reduce resistance and prevent bogging down. Firm surfaces can accommodate wider buckets for increased material movement per cycle.

Job site space constraints may necessitate narrower buckets, particularly in urban environments or when working alongside existing structures. Always ensure adequate operational clearance when selecting bucket width.

Grading Bucket Width (inches)

Grading buckets serve specialized purposes in excavation work, featuring distinctive designs optimized for creating smooth, level surfaces rather than maximum digging power. Understanding their width specifications and applications is essential for effective implementation.

Grading Bucket Characteristics

Grading buckets typically feature significantly wider profiles than standard digging buckets, often ranging from:

36-60 inches (900-1500 mm) for mini excavators

48-84 inches (1200-2100 mm) for mid-sized excavators

72-120 inches (1800-3000 mm) for larger machines

These buckets have relatively shallow depths compared to their width, creating a design specifically engineered for spreading material evenly and creating smooth, finished surfaces. The cutting edge is usually straight rather than toothed, allowing for cleaner grading results.

Specialized Grading Applications

Slope grading represents one of the primary applications for these specialized buckets. Their wide, shallow design enables operators to create consistent angles on embankments, drainage channels, and landscaping features. The extended width creates more consistent results while reducing the number of passes required.

Final grade preparation benefits tremendously from proper grading bucket implementation. These attachments excel at distributing and leveling backfill around foundations, preparing building pads, and creating the precise elevations required before concrete pouring or base material installation.

Ditch cleaning operations often utilize grading buckets to remove sediment accumulation and restore proper flow profiles. Their wide, flat design efficiently removes material while maintaining the engineered contours of drainage systems.

Selection Considerations for Grading Buckets

When selecting a grading bucket width, material type significantly influences optimal dimensions. Cohesive soils like clay allow for wider buckets, while looser materials may require somewhat narrower widths to prevent material spillage during operation.

Precision requirements dictate appropriate width selection as well. Projects with stringent grading tolerances may benefit from narrower grading buckets that provide greater operator control, while less demanding applications can utilize wider buckets for increased productivity.

Machine visibility factors into effective width selection. The operator must maintain clear sightlines to the bucket edges when performing precision grading. Excessively wide buckets may create visibility challenges from the cab position, particularly on smaller machines.

FAQ

①How do I know what size bucket I need for my excavator?

To determine the appropriate bucket size for your excavator, first identify your machine's operating weight in tons. Then consider the material density you'll primarily handle and your typical applications. As a general rule, match the bucket size to your excavator's weight class following manufacturer recommendations. For specialized applications, consult with equipment professionals who can recommend optimal bucket dimensions for your specific needs.

②Can I use different-sized buckets on my excavator?

Yes, most excavators can accommodate various bucket sizes within a certain range appropriate for their weight class. Using quick couplers makes changing between different bucket sizes more efficient. However, always stay within the manufacturer's recommended weight capacity limits to ensure safe operation and prevent damage to your machine's hydraulic system and structural components.

③What's the difference between a general-purpose and heavy-duty bucket?

General purpose buckets feature standard thickness steel and are designed for everyday digging in moderate conditions like topsoil and clay. Heavy-duty buckets incorporate thicker steel, additional reinforcement plates, and wear-resistant materials to withstand abrasive or high-impact applications such as rock excavation, demolition, or quarry work. Heavy-duty buckets typically weigh more and may slightly reduce your excavator's overall lifting capacity.

④How does bucket size affect excavator performance?

Bucket size directly impacts excavator performance in several ways. Larger buckets increase material moved per cycle but reduce breakout force and may slow cycle times. They also increase fuel consumption and can potentially destabilize smaller machines. Conversely, appropriately sized buckets optimize fuel efficiency, cycle speeds, and overall productivity while maintaining machine stability and component longevity.

⑤How often should excavator buckets be replaced?

Replacement frequency depends on usage intensity, material types, and bucket quality. Under normal conditions, quality buckets might last 3-5 years before requiring replacement. Heavy-duty applications in abrasive materials may necessitate replacement within 1-2 years. Regular inspection for wear patterns, cracks, or deformation is essential. Implementing a proactive maintenance schedule with periodic rebuilding of wear areas can significantly extend bucket lifespan.

Choose Tiannuo

Selecting the appropriate bucket size involves careful consideration of multiple factors, from machine specifications to application requirements. The right bucket size optimizes productivity, reduces operational costs, and extends equipment lifespan. Whether you're working with a compact 1-ton mini excavator or a massive 40-ton machine, matching bucket dimensions to your specific needs ensures peak performance.

For railway construction, maintenance projects, or any heavy construction application, properly sized buckets make all the difference in project timelines and profitability. Tiannuo's range of high-strength, wear-resistant excavator buckets offers the perfect solution for operations ranging from precision trenching to large-scale earthmoving.

Our buckets feature capacities from 0.1 to 5.0 cubic meters, widths from 500 to 2000 mm, and weights from 100 to 2000 kg. With both pin-on and quick coupler attachment options, they're compatible with virtually all major excavator brands and models.

For expert guidance on selecting the optimal bucket for your specific equipment and application needs, contact our team of specialists at tn@stnd-machinery.com. Tiannuo's commitment to quality and customization ensures you'll receive the perfect excavator attachment solution for your operational requirements.

References

Construction Equipment Guide. "Excavator Bucket Selection: Matching Size to Application." Construction Equipment Manual, Volume 14, 2023.

Johnson, Robert T. "Heavy Equipment Attachments: Optimizing Excavator Performance." Industrial Machinery Review, Issue 42, 2022.

International Journal of Construction Engineering. "The Impact of Bucket Dimensions on Excavator Efficiency." Volume 8, Issue 3, 2023.

Wilson, Emily. "Excavator Attachment Selection Guidelines for Construction Professionals." Construction Technology Review, 2024.

Zhang, Wei and Thompson, Mark. "Optimizing Excavator Productivity Through Proper Attachment Selection." Heavy Equipment Quarterly, Spring Edition, 2023.

About Author: Arm

Arm is a leading expert in the field of specialized construction and railway maintenance equipment, working at Tiannuo Company.