What tire models are suitable for dump truck anti-skid tracks?

When operating dump trucks in challenging terrain conditions, selecting the right tire models for dump truck anti-skid tracks becomes crucial for maintaining optimal performance and safety. The compatibility between your existing tires and anti-skid track systems directly impacts traction, stability, and overall operational efficiency. Most anti-skid tracks are specifically engineered to accommodate the 1200 series tire models, which represent the industry standard for heavy-duty construction and mining applications. These track systems are designed with bolt-on installation mechanisms that secure directly over your existing tires, transforming your dump truck's capabilities across mud, snow, gravel, sand, and various off-road conditions. Understanding tire compatibility ensures you make informed decisions that enhance your equipment's performance while maintaining cost-effectiveness and operational reliability in demanding work environments.

Applicable Tire Models: 1200

Standard 1200 Series Specifications

The 1200 series tire models represent the gold standard for dump truck applications, particularly when paired with anti-skid track systems. These tires feature robust construction with reinforced sidewalls and specialized tread patterns that complement track attachment mechanisms. Dump truck anti-skid tracks designed for 1200 series tires typically accommodate rim sizes ranging from 20 to 25 inches, with load ratings suitable for heavy-duty construction equipment. The casting workmanship ensures precise fitment and durability under extreme operating conditions.

Load Capacity and Performance Benefits

When installing anti-skid tracks on 1200 series tires, operators experience significant improvements in load distribution and ground contact pressure. The enhanced surface area reduces soil compaction while maintaining superior traction across various terrain types. These track systems weigh approximately 1500kg per set, which actually contributes to better stability rather than hindering performance. The additional weight helps prevent tire slip and provides consistent ground contact, especially beneficial when navigating steep inclines or unstable surfaces.

Terrain-Specific Advantages

The 1200 series compatibility with anti-skid tracks excels across diverse operational environments. In muddy conditions, the tracks prevent sinking and provide continuous forward momentum. Snow operations benefit from the increased surface area and specialized tread design that maintains grip without clogging. Gravel and rocky terrain applications show reduced puncture risk and improved traction control. Sand operations demonstrate enhanced flotation characteristics, preventing the vehicle from becoming stuck in loose material.

Applicable Tire Models: Customizable

Flexible Sizing Options

Beyond the standard 1200 series, modern dump truck anti-skid tracks offer customizable solutions for various tire configurations. This flexibility accommodates different manufacturers' specifications and allows for retrofitting existing fleets without requiring complete tire replacement. Customization options include adjustable mounting brackets, variable track widths, and specialized cleats designed for specific operational requirements. The engineering team can modify track dimensions to match unique tire profiles while maintaining structural integrity and performance standards.

OEM and ODM Support Capabilities

Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) support ensures that customized anti-skid tracks meet exact specifications for your fleet requirements. This support includes detailed engineering analysis, prototype development, and testing protocols that verify performance across intended applications. The customization process involves comprehensive consultation to understand operational demands, environmental conditions, and performance expectations. Quality control measures ensure that custom solutions maintain the same reliability and durability standards as standard configurations.

Integration with Existing Equipment

Customizable track systems seamlessly integrate with existing dump truck configurations without requiring significant modifications to the vehicle itself. The bolt-on installation method remains consistent across custom applications, ensuring maintenance teams can install and remove tracks efficiently. Compatibility extends to various hydraulic systems, suspension configurations, and axle specifications. This adaptability makes customized solutions cost-effective for fleet operators managing diverse equipment portfolios.

Selection Criteria

Operational Environment Assessment

Selecting appropriate tire models for dump truck anti-skid tracks requires thorough evaluation of operational environments and performance requirements. Primary considerations include soil conditions, weather patterns, load requirements, and terrain variability. Muddy environments demand tracks with aggressive tread patterns and self-cleaning capabilities. Rocky terrain necessitates reinforced track construction with puncture-resistant materials. Snow operations require specialized compounds that maintain flexibility in cold temperatures while providing superior grip.

Performance and Durability Factors

Track performance depends on several critical factors including material composition, manufacturing quality, and design engineering. High-quality tracks feature advanced rubber compounds that resist cracking, chunking, and premature wear. The casting process ensures consistent density and eliminates weak points that could lead to failure. Proper selection considers expected service life, maintenance requirements, and replacement costs. Performance metrics include traction coefficient, wear resistance, and operational temperature range.

Installation and Maintenance Considerations

Ease of installation significantly impacts operational efficiency and maintenance costs. Quality dump truck anti-skid tracks feature user-friendly installation procedures that minimize downtime and labor requirements. The bolt-on system allows for quick attachment and removal, enabling operators to adapt to changing conditions rapidly. Maintenance considerations include cleaning procedures, inspection protocols, and replacement part availability. Proper selection ensures long-term reliability and cost-effectiveness throughout the equipment's service life.

FAQ

What tire sizes are compatible with dump truck anti-skid tracks?

Most dump truck anti-skid tracks are designed for 1200 series tires, though customizable options accommodate various sizes. The standard compatibility includes rim sizes from 20 to 25 inches with appropriate load ratings for heavy-duty applications.

How much do anti-skid tracks weigh?

A complete set of anti-skid tracks weighs approximately 1500kg. This additional weight actually improves stability and traction rather than hindering performance, providing better ground contact and reducing slip.

Can anti-skid tracks be installed on different tire brands?

Yes, anti-skid tracks are designed to accommodate various tire brands as long as they meet the size and load specifications. The bolt-on installation system provides universal compatibility across manufacturers.

What terrain types benefit most from anti-skid tracks?

Anti-skid tracks excel in mud, snow, gravel, sand, and general off-road conditions. They prevent sinking, reduce ground pressure, and provide superior traction compared to standard tires alone.

Are customized tracks available for specific applications?

Yes, OEM and ODM support is available for customized solutions. This includes modified dimensions, specialized tread patterns, and application-specific designs to meet unique operational requirements.

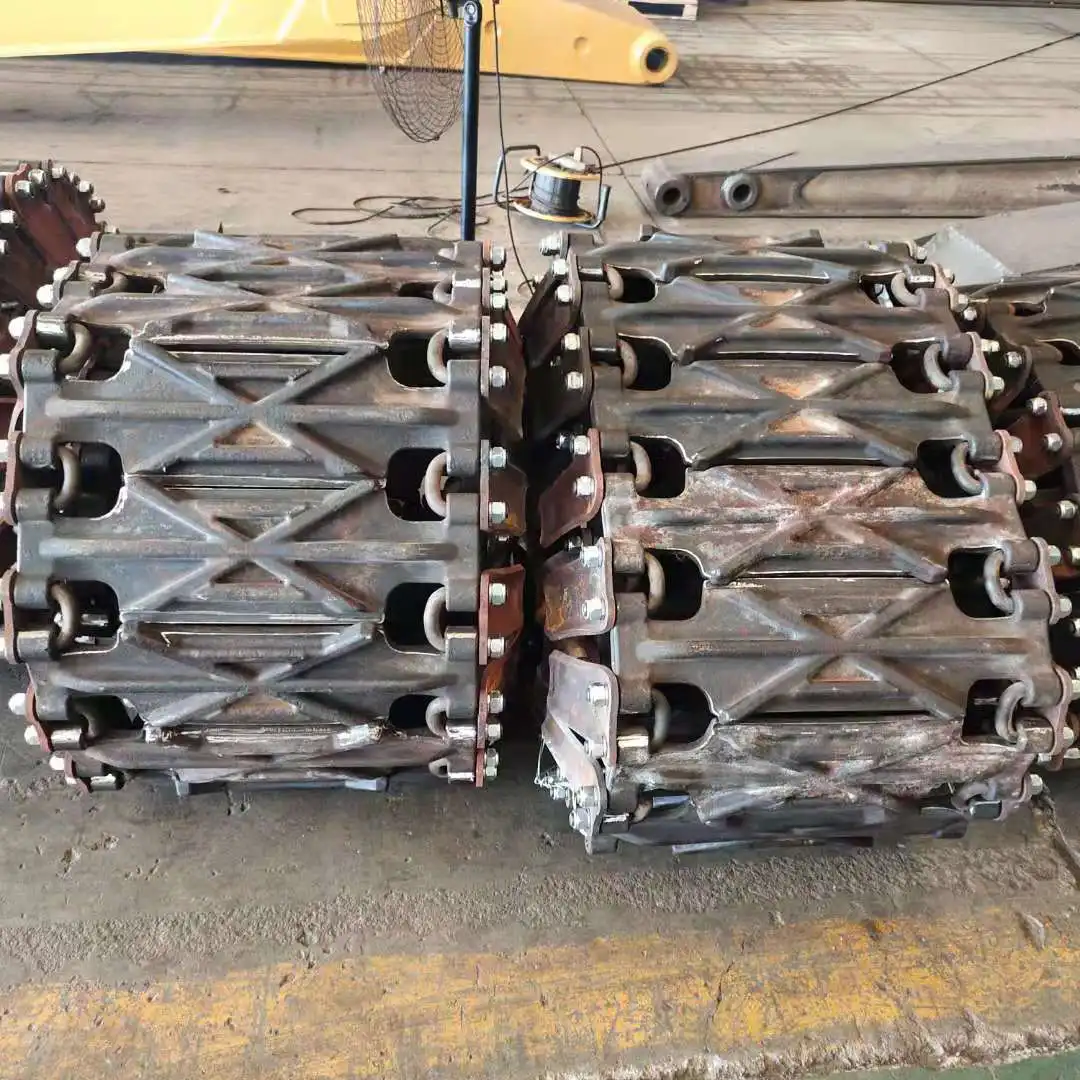

Crafted with precision casting, dump truck anti-skid tracks are built to last, even in the harshest conditions. Designed to fit 1200 tire models (and fully customizable to match your specific needs), they bring unbeatable stability with a weight of 1500kg per set, ensuring your truck stays grounded when it matters most.

Three core benefits: anti-slip technology to keep control on icy or wet surfaces, anti-sinking design to prevent getting bogged down in sand or mud, and anti-scratch protection to shield your tires from sharp rocks and debris. Whether you're navigating off-road sites, snowy landscapes, or gravel-strewn paths, these tracks turn challenging terrains into manageable ones.

Worried about installation? Don't be. With a simple bolt-on design, setup is quick and hassle-free – no complex tools or lengthy downtime required. Plus, we offer full OEM & ODM support, so you can tailor every detail to fit your fleet's unique requirements.

If your operations are held back by terrain-related delays or damage, it's time to upgrade. These tracks don't just solve problems – they boost efficiency, reduce maintenance costs, and keep your projects on schedule.

Ready to take your dump truck performance to the next level? Don't wait. Reach out today to arm@stnd-machinery.com to learn more about pricing, customization options, or installation details. Let Tiannuo's Anti-Skid Tracks turn your toughest challenges into smooth sailing. Your fleet deserves it. Contact us now!

References

- Heavy Equipment Traction Systems: Engineering Principles and Applications - Society of Automotive Engineers Technical Paper Series

- Off-Road Vehicle Performance Enhancement through Track Systems - Journal of Terramechanics Research

- Construction Equipment Tire and Track Selection Guidelines - International Association of Equipment Manufacturers

- Mining Vehicle Traction Control Systems: Technical Specifications - Mining Engineering Handbook

- Dump Truck Operational Efficiency in Challenging Terrain - Construction Industry Research Foundation

About Author: Arm

Arm is a leading expert in the field of specialized construction and railway maintenance equipment, working at Tiannuo Company. Tiannuo specializes in manufacturing a wide range of products, including railway maintenance equipment like railway sleeper changing machines and screening machines, excavator modification equipment such as excavator lifting cabs, various engineering arms for excavators, excavator accessories like digging buckets, and engineering vehicle auxiliary equipment like loader buckets.