Ballast plough

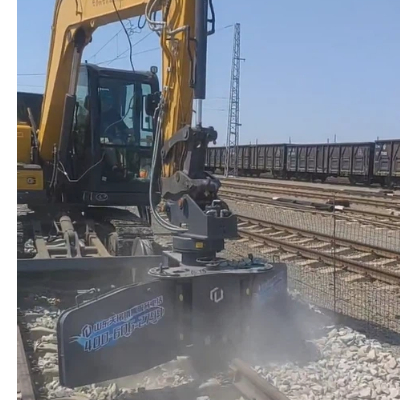

Sleeper Ballast Cleaning: Ballast is cleaned from the sleeper rail bearing grooves and sides to ensure the sleeper working surface is exposed for easy inspection or replacement.

Rapid Backfilling: After sleeper replacement or track lifting, the ballast layer is efficiently backfilled and initially leveled.

Applicable excavator model: 15t

Applicable track gauge: 1520mm

Maximum height: 1250mm

Maximum width: 2814mm

Rated flow rate: 40Mpa

Rotation angle: 360°

Working angle: 180°

- Product Description

The Ballast plough is an excavator attachment specifically designed for railway track bed maintenance. It is used to efficiently and accurately shape, level, and backfill ballast (sleeper crushed stone layer). Through hydraulically driven plow blades, it can quickly level the ballast around and under the sleepers, restoring the standard cross-sectional shape of the track bed and laying the foundation for subsequent tamping or track adjustment.

What is a Ballast Plough?

The ballast plow is a crucial "sculptor" and "cleaner" in railway track bed maintenance. As a highly efficient attachment for excavators, it is specifically designed for the rapid and orderly preparation of the ballast (crushed stone layer) under and on both sides of railway sleepers. It is one of the core pieces of equipment for restoring the standard geometry of the track bed and improving the quality of subsequent operations.

Specification

| No. | Name | unit | values |

| 1 | Applicable excavator model | t | 15 |

| 2 | Applicable track gauge | mm | 1520 |

| 3 | Maximum height | mm | 1250 |

| 4 | Maximum width | mm | 2814 |

| 5 | Rated flow rate | L/min | 40 |

| 6 | Rotation angle | ° | 360 |

| 7 | Working angle | ° | 180 |

Core Functions

**Efficient Shaping, Restoring Standard Track Bed Profile**

Through hydraulically controlled plows, loosened, deformed, and overflowing ballast caused by train cyclic loads or natural settlement are leveled, gathered, and shaped back into the trapezoidal cross-section required by design. This not only ensures smooth drainage of the track bed but is also the foundation for the long-term stability of the track structure.

**Precise Ballast Removal, Exposing Key Working Surfaces**

Before sleeper replacement, pad adjustment, or fastener maintenance, ballast accumulated in and around the sleeper rail bearing grooves is quickly removed, fully exposing the work area. This significantly reduces the time and intensity of manual cleaning, creating a clear and unobstructed working interface for refined maintenance.

**Uniform Ballast Backfilling, Improving Tamping Quality and Efficiency**

Before tamping operations, ballast is pre-distributed evenly within the sleeper boxes to avoid tamping voids or unbalanced stress caused by uneven aggregate distribution. After sleeper replacement, ballast backfilling and preliminary compaction can be completed quickly, fully preparing for subsequent tamping processes and forming an efficient production line.

Irreplaceable Operational Value

**Quality Precedence:** The regularity of the track bed profile is a prerequisite for precise adjustment of track geometry. The pre-shaping by the ballast plow directly determines the final quality and efficiency of subsequent tamping, track lifting, and other processes.

Economical and Efficient: One excavator equipped with a ballast plow can replace the manual labor of dozens of people for cleaning and tidying, significantly shortening track closure time and reducing overall maintenance costs.

Flexible and Adaptable: Particularly suitable for complex areas that are difficult for large shaping machinery to access, such as station yards, turnout areas, and bridge-tunnel transition sections, enabling precise, localized, and rapid processing.

Workshop Display

Our production facilities at Tiannuo Machinery are equipped with cutting-edge technology, ensuring every product meets the highest quality and durability standards. Visit our workshop gallery to see the meticulous manufacturing process from design to final assembly.

FAQ

Q: What makes Tiannuo’s Ballast Plow stand out from the competition?

A: Tiannuo's Ballast Plow features a high-strength wear-resistant structure, precision hydraulic control, and intelligent angle adjustment, delivering superior durability, operational flexibility, and efficiency in railway ballast shaping.

Q: Can the Ballast Plow be customized for different railway projects?

A: Yes. Our Ballast Plow supports customizable blade widths, adjustable mounting brackets, and hydraulic configurations to suit varying track gauges, ballast types, and specific project requirements.

Q: How easy is it to operate a Tiannuo Ballast Plow?

A: Designed with intuitive hydraulic controls and compatible with standard excavator operation systems, the Ballast Plow can be mastered quickly with minimal training, even for operators new to railway maintenance.

Q: What kind of maintenance does a Tiannuo Ballast Plow require?

A: Built for rugged use, the Ballast Plow requires only routine inspection of wear parts such as blades and pins, along with standard hydraulic system checks, ensuring low upkeep and maximum uptime.

Contact Us

Ready to enhance your railway maintenance with Tiannuo Railway Excavator Ballast Plough? Contact us at arm@stnd-machinery.com for more information. Our team is here to provide solutions tailored to your needs.

YOU MAY LIKE

VIEW MORERailway excavator modification and attachment

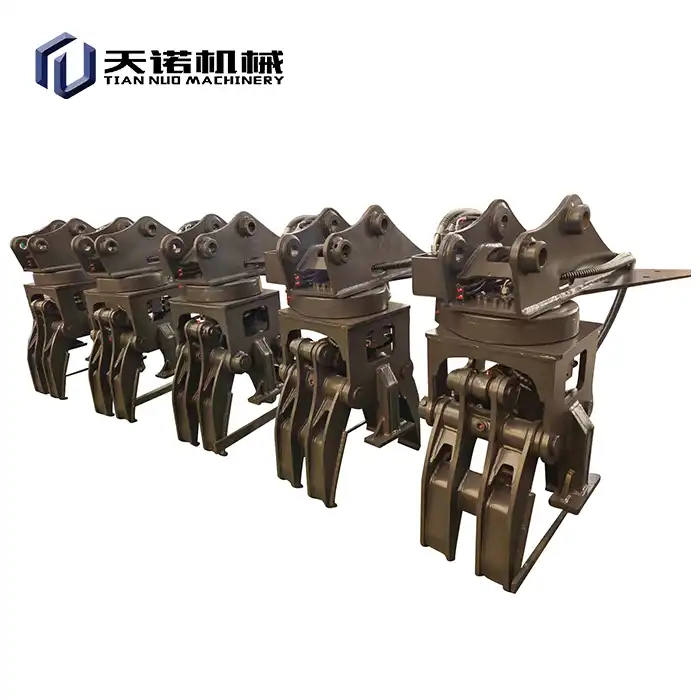

VIEW MORERailway excavator modification and attachment VIEW MORERailroad Excavator Concrete Sleeper Grab

VIEW MORERailroad Excavator Concrete Sleeper Grab VIEW MOREExcavator Brush Cutter

VIEW MOREExcavator Brush Cutter VIEW MORERailroad excavator

VIEW MORERailroad excavator VIEW MOREExcavator Screening Bucket

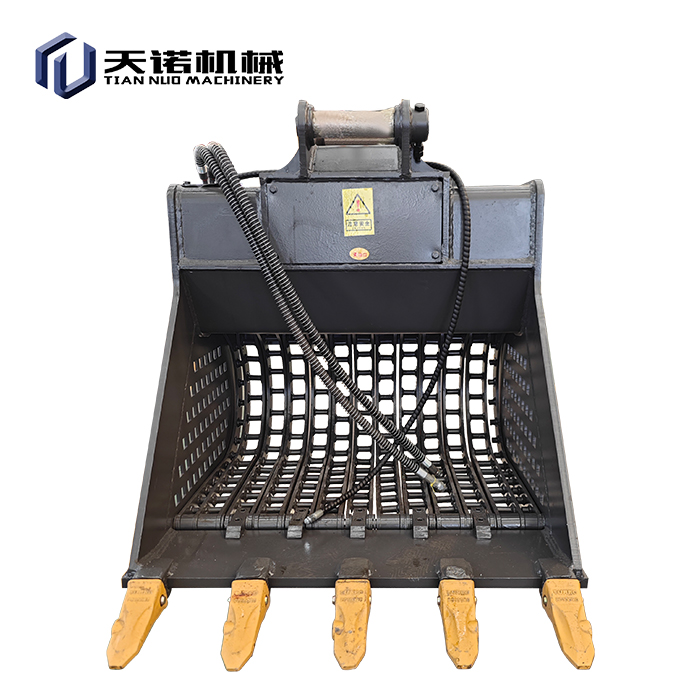

VIEW MOREExcavator Screening Bucket VIEW MOREPremium Rail Excavator Double Head Tamping Machine

VIEW MOREPremium Rail Excavator Double Head Tamping Machine VIEW MORERailroad switch ballast tamper

VIEW MORERailroad switch ballast tamper VIEW MORERailroad Ballast Car

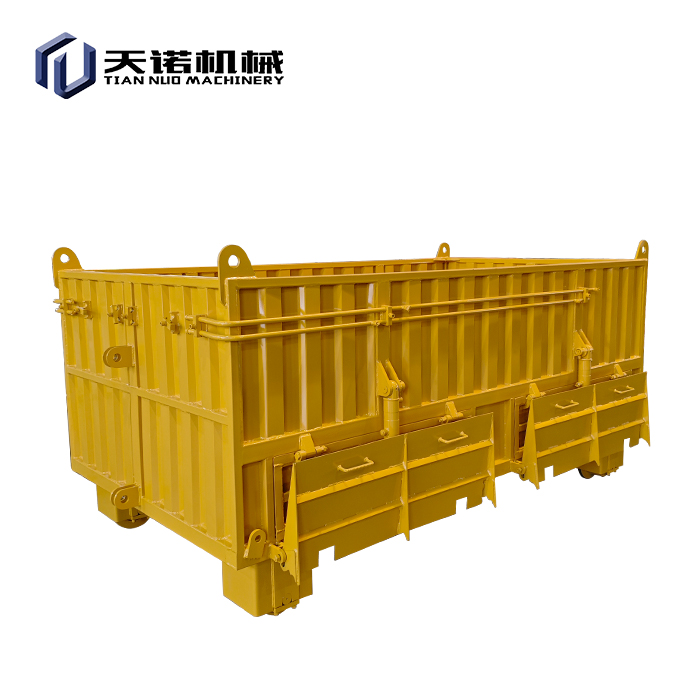

VIEW MORERailroad Ballast Car

_1766459868951.webp)