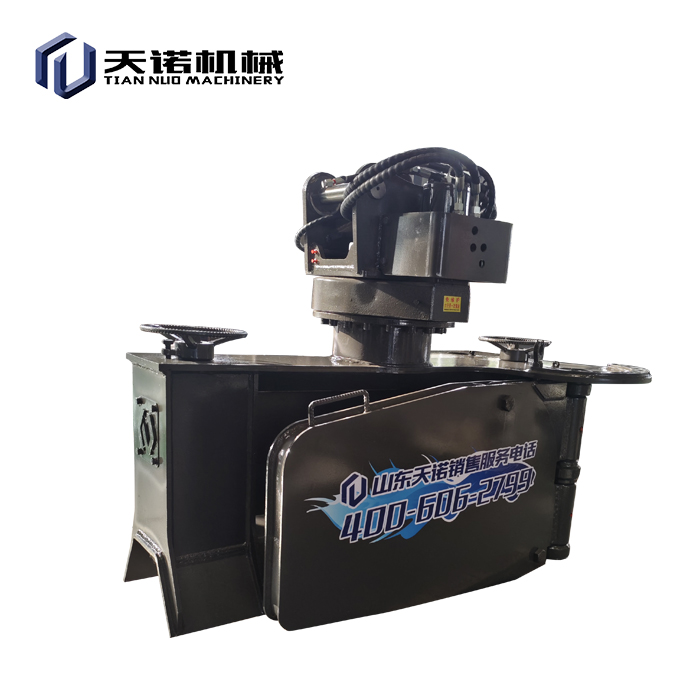

Ballast Tamper(Gasoline Type)

- Product Description

A Ballast Tamper(Gasoline Type) is an essential piece of railway maintenance equipment designed to compact and stabilize the ballast beneath railway sleepers. By ensuring proper ballast consolidation, tampers enhance track stability, alignment, and longevity, contributing to safer and more efficient rail operations. Ideal for mainline tracks, metro systems, and industrial railways, our ballast tampers combine robust engineering with user-friendly operation to meet the demands of modern rail networks.

Key Features:

Independent Power Source: Built-in gasoline engine provides strong and reliable vibration without relying on the excavator’s hydraulic system.

Flexible Operation: Easily mounted on excavators; rotation and movement are fully controlled by the excavator boom.

High Tamping Efficiency: Delivers powerful and uniform compaction to improve track stability and ballast density.

Durable Construction: Heavy-duty frame and high-strength materials ensure long service life in demanding rail environments.

Simple Maintenance: Modular design allows easy servicing and quick replacement of key components.

Specifications:

| Applicable tonnage(ton) | 6-9 |

| Applicable track gauge(mm) | 1435/1520 |

| Tamper head vibration frequency(hz) | 63.5 |

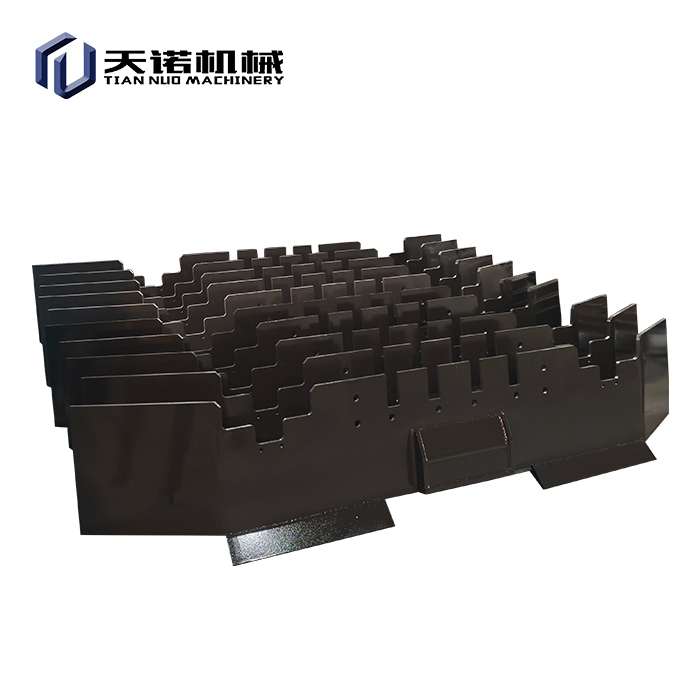

| Number of tamping head(pcs) | 8 |

| Rotation Angle | 360 |

| Maximum compaction depth(mm) | 400 |

| Clamping range(mm) | 320-550 |

| Gasoline engine power(kw) | 6.6(GX390) |

| Rotating rated flow rate(L/min) | 40 |

| Rotating working pressure(bar) | 12 |

| Weight(kg) | 852 |

| Package size(mm) | 2080*740*1630 |

Applications:

Mainline Track Maintenance: Regular upkeep of high-speed and freight rail corridors.

Transit Systems: Metro, light rail, and tramway track stabilization.

Construction Projects: Post-renewal tamping for new tracks or upgraded sections.

Mining and Industrial Rail: Heavy-duty applications in rugged environments.

FAQ

Q1: How often does the product need maintenance?

A1: Regular maintenance is recommended every 500 hours of operation, including checks on hydraulic systems, lubrication, and inspection of wear parts. Tiannuo provides comprehensive maintenance guides and support.

Q2: Can the product be customized?

A2: Yes, we offer customization to meet the specific requirements of your railway maintenance projects. Contact us to discuss your needs.

Q3: What is the delivery time for the product?

A3: Our standard delivery time is 6-8 weeks, depending on the level of customization required.

Contact Us

Ready to optimize your railway maintenance operations with a high-performance Ballast Tamper(Gasoline Type) ? Reach out to us at arm@stnd-machinery.com to discuss your needs and receive a personalized quote.

YOU MAY LIKE

VIEW MORERail Track Trolley

VIEW MORERail Track Trolley VIEW MORERailway excavator modification and attachment

VIEW MORERailway excavator modification and attachment VIEW MORERailway Excavator Cleaning Bucket

VIEW MORERailway Excavator Cleaning Bucket VIEW MOREExcavator rail clamp

VIEW MOREExcavator rail clamp VIEW MORERailroad switch ballast tamper

VIEW MORERailroad switch ballast tamper VIEW MOREHigh-vibration hydraulic ballast tamping machine

VIEW MOREHigh-vibration hydraulic ballast tamping machine VIEW MORERailway Excavator Ballast Plow

VIEW MORERailway Excavator Ballast Plow VIEW MOREBallast Scrapper

VIEW MOREBallast Scrapper

_1767151461922.webp)