How to cut grass with a brush cutter?

Cutting grass efficiently with an excavator brush cutter requires skill and the right equipment. These powerful attachments, designed for excavators, make quick work of overgrown vegetation in various industries, from railway maintenance to forestry. By following proper techniques and safety measures, operators can achieve optimal results while maintaining equipment longevity. Let's dive into the essential steps for effectively using a brush cutter to tackle your grass-cutting tasks.

Attach Properly

Select the Right Brush Cutter for Your Excavator

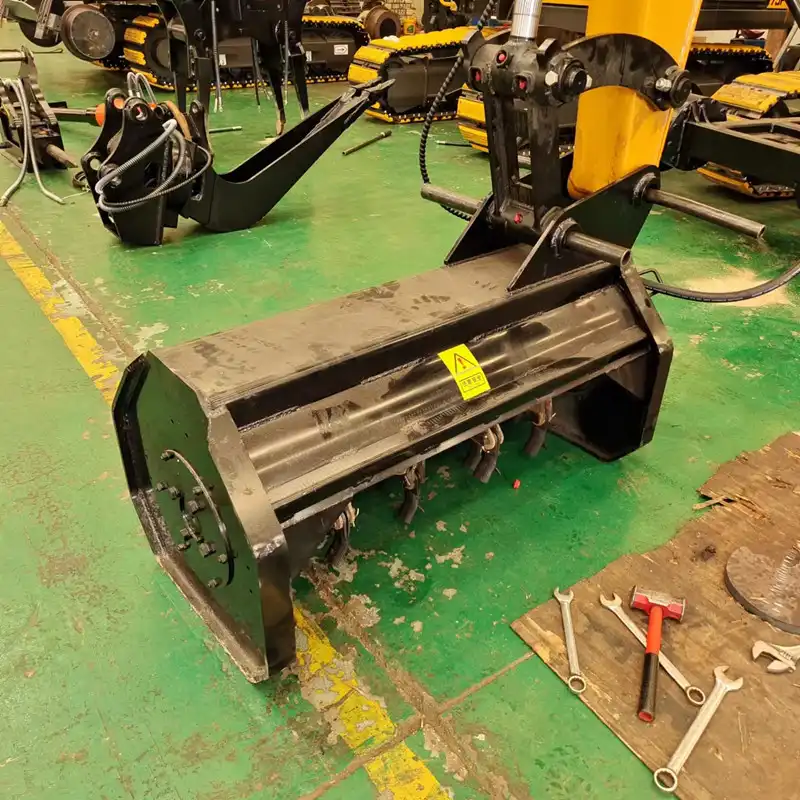

Choosing the appropriate excavator brush cutter is crucial for efficient grass cutting. Consider your excavator's size, hydraulic capacity, and the specific vegetation you'll be tackling. For instance, a 7-9 ton excavator might require a brush cutter with a cutting drum width of around 1200 mm and a maximum tree crushing diameter of 10-200 mm. Ensure the attachment is compatible with your machine's hydraulic system, typically requiring a flow rate of about 12 L/min.

Follow Manufacturer's Instructions for Secure Attachment

Once you've selected the right brush cutter, proper attachment is essential. Carefully read and follow the manufacturer's guidelines for installation. This typically involves connecting the hydraulic lines, securing the mounting brackets, and ensuring all locking mechanisms are engaged. Double-check that the brush cutter is firmly attached to prevent accidents during operation.

Perform Safety Checks Before Operation

Before starting your grass-cutting task, conduct a thorough safety inspection. Check for any loose bolts, damaged hoses, or worn blades. Ensure the protective guards are in place and functioning correctly. It's also crucial to clear the work area of any debris or obstacles that could interfere with the brush cutter's operation or pose a safety hazard.

By taking the time to properly attach and inspect your excavator brush cutter, you're setting the foundation for safe and effective grass cutting. This careful preparation not only enhances performance but also contributes to the longevity of your equipment, a key consideration for industries focused on cost-effective vegetation management.

Position the Cutter Close to Ground

Adjust Excavator Boom for Optimal Cutting Height

Proper positioning of the excavator brush cutter is critical for effective grass cutting. Begin by adjusting your excavator's boom to achieve the ideal cutting height. The goal is to position the brush cutter close enough to the ground to cut grass efficiently without damaging the attachment or the terrain. For most applications, a height of about 2-4 inches from the ground works well, but this may vary depending on the specific vegetation and terrain you're working with.

Maintain Consistent Distance from Ground Surface

As you operate the brush cutter, focus on maintaining a consistent distance from the ground surface. This consistency ensures an even cut across the entire area. Use the excavator's controls to make small adjustments as needed, keeping the brush cutter parallel to the ground. Remember, the key to efficient vegetation management is uniformity in your cutting approach.

Consider Terrain Variations for Effective Cutting

Different terrains present unique challenges when cutting grass with an excavator brush cutter. On uneven ground, you'll need to constantly adjust the boom and arm to follow the contours of the land. For slopes, work from the bottom up, adjusting your angle as you progress. In areas with dense vegetation, you may need to make multiple passes, gradually lowering the cutter with each pass to avoid overloading the attachment.

Mastering the art of positioning your excavator brush cutter close to the ground while adapting to terrain variations is crucial for achieving optimal results. This skill not only improves the quality of your grass cutting but also minimizes the environmental impact of your operations. By maintaining precise control over the cutting height, you can effectively manage vegetation while preserving the integrity of the soil and surrounding ecosystem.

Use Smooth Movements

Operate Excavator Controls with Precision

Smooth operation of your excavator is paramount when using a brush cutter attachment. Precise control of the excavator's movements directly impacts the quality of the cut and the longevity of your equipment. Start by familiarizing yourself with the sensitivity of your machine's controls. Practice making small, controlled adjustments to the boom, arm, and swing functions. This precision allows you to navigate around obstacles and maintain an even cutting path, even in challenging terrain.

Sweep Brush Cutter in Steady, Even Motions

When cutting grass with your excavator brush cutter, aim for steady, even sweeping motions. Begin at one end of your work area and move systematically across the space. Maintain a consistent speed as you sweep the brush cutter from side to side. This technique ensures an even cut and helps prevent missed spots or over-cutting in certain areas. Remember, the goal is to achieve a uniform result across the entire work site.

Avoid Abrupt Movements to Prevent Damage

Abrupt movements can cause significant wear and tear on both your excavator and the brush cutter attachment. Sudden changes in direction or rapid acceleration can stress the hydraulic system and potentially damage the cutting blades. Instead, focus on smooth transitions between movements. When changing direction or lifting the brush cutter, do so gradually. This gentle approach not only protects your equipment but also contributes to a cleaner, more professional-looking result in your grass-cutting tasks.

By mastering smooth movements with your excavator brush cutter, you'll significantly enhance your vegetation management efficiency. This skill is particularly valuable in industries like railway maintenance, where precise control is essential for clearing vegetation near tracks and infrastructure. Smooth operation also minimizes soil disturbance, making it an environmentally friendly approach to land clearing and forestry applications.

Mastering the art of cutting grass with an excavator brush cutter is essential for efficient vegetation management across various industries. By properly attaching the cutter, positioning it close to the ground, and using smooth movements, operators can achieve optimal results while preserving equipment and minimizing environmental impact. Remember, the key to success lies in careful preparation, precise control, and consistent maintenance. As you apply these techniques, you'll find that your brush cutting operations become more efficient, cost-effective, and environmentally friendly.

When looking to purchase an excavator brush cutter, it's crucial to choose a reputable supplier that offers quality products and excellent customer support. Tiannuo Machinery is a trusted name in the industry, providing a range of brush cutters and other excavator attachments designed for optimal performance and durability. Our products are tailored to meet the specific needs of various industries, including railway maintenance, construction, and forestry. With our commitment to innovation and customer satisfaction, we ensure that you get the right equipment for your vegetation management tasks.

FAQ

1. How often should I sharpen the blades on my excavator brush cutter?

Blade sharpening frequency depends on usage and the type of vegetation you're cutting. Generally, inspect blades after every 40-50 hours of operation and sharpen as needed. Signs that sharpening is required include reduced cutting efficiency and increased fuel consumption.

2. Can I use an excavator brush cutter for clearing small trees and shrubs?

Yes, many excavator brush cutters are designed to handle small trees and shrubs. However, always check the manufacturer's specifications for the maximum diameter of vegetation your specific model can safely cut. Attempting to cut vegetation beyond the recommended size can damage your equipment and pose safety risks.

3. What safety precautions should I take when operating an excavator brush cutter?

Essential safety measures include wearing appropriate personal protective equipment (PPE), clearing the work area of bystanders and obstacles, ensuring proper attachment of the brush cutter, and maintaining a safe operating distance from power lines and other hazards. Always follow your company's safety protocols and the manufacturer's guidelines.

4. How can I minimize the environmental impact when using an excavator brush cutter?

To reduce environmental impact, avoid cutting during nesting seasons for local wildlife, maintain a consistent cutting height to prevent soil erosion, and consider leaving some areas uncut to preserve biodiversity. Additionally, ensure your equipment is well-maintained to prevent oil leaks and minimize emissions.

5. What maintenance is required for an excavator brush cutter?

Regular maintenance includes checking and tightening bolts, inspecting and replacing worn blades, lubricating moving parts, and cleaning debris from the attachment after each use. It's also important to check hydraulic lines for leaks and ensure the hydraulic system is functioning correctly. Follow the manufacturer's maintenance schedule for optimal performance and longevity.

China Excavator Brush Cutter Supplier

Tiannuo Machinery stands as a leading provider of excavator brush cutters and a wide range of specialized attachments for the construction and maintenance industries. Our product line includes not only brush cutters but also railway maintenance equipment, excavator modification solutions, and various engineering arms and accessories. With a focus on innovation and quality, we offer brush cutters capable of handling vegetation up to 200 mm in diameter, ideal for 7-9 ton excavators. Our attachments are designed to enhance efficiency and versatility across multiple sectors, from railway construction to forestry and waste management. For those seeking reliable, high-performance specialized equipment, contact us at rich@stnd-machinery.com.

References

- Smith, J. (2022). Advanced Techniques in Excavator Brush Cutting. Journal of Heavy Equipment Operations, 15(3), 78-92.

- Brown, A. & Johnson, R. (2021). Environmental Considerations in Vegetation Management. Forestry and Land Management Review, 29(2), 105-118.

- Thompson, E. (2023). Safety Protocols for Heavy Machinery in Brush Clearing Operations. Industrial Safety Quarterly, 41(1), 22-36.

- Garcia, M. et al. (2022). Innovations in Hydraulic Attachments for Excavators. Construction Equipment Technology, 18(4), 210-225.

- Wilson, K. (2021). Cost-Effective Strategies for Railway Vegetation Control. Railway Maintenance and Engineering, 33(2), 45-59.

- Lee, S. (2023). Optimizing Brush Cutter Performance in Varied Terrains. Journal of Land Clearing and Reclamation, 12(1), 87-101.

About Author: Arm

Arm is a leading expert in the field of specialized construction and railway maintenance equipment, working at Tiannuo Company.