Tyre Protection Chains for Wheel Loaders

When operating wheel loaders in demanding environments, protecting your equipment investment becomes paramount. A loader tire protection chain serves as the ultimate safeguard against premature tire wear, catastrophic damage, and operational downtime. These specialized protective systems wrap around wheel loader tires, creating a robust barrier between expensive rubber and harsh working surfaces. Whether you're navigating rocky terrain in mining operations, clearing debris in construction zones, or managing materials in industrial settings, tire protection chains transform your wheel loader into a more resilient and cost-effective machine. The technology behind these protective systems has evolved significantly, offering operators enhanced durability, improved traction, and substantial cost savings that can transform operational economics across various industries.

Tyre Life Extended

The economic impact of premature tire replacement on wheel loader operations cannot be overstated. Heavy-duty loader tires represent a significant operational expense, often costing thousands of dollars per replacement. When operators deploy tire protection chains, they're essentially investing in a protective barrier that can extend tire lifespan by up to three times the normal expectancy.

Tire Wear Patterns

Wheel loader tires face multiple destructive forces during operation. Sharp rocks, metal debris, and abrasive surfaces create cuts, punctures, and accelerated tread wear that dramatically reduce tire life. Protection chains absorb these impacts, distributing stress across their metal mesh structure rather than allowing direct contact with vulnerable rubber compounds. The chains act as a sacrificial layer, taking the punishment that would otherwise destroy expensive tires.

Material Engineering Advantages

Modern loader tire protection chain systems utilize advanced metallurgy to maximize durability. Chrome-manganese steel alloys provide exceptional wear resistance while maintaining flexibility necessary for proper tire function. These materials resist work-hardening under repeated stress, ensuring consistent protection throughout extended service periods. The mesh design allows chains to flex with tire deformation while maintaining protective coverage across both sidewalls and tread areas.

Quantifiable Cost Benefits

Operations managers consistently report dramatic cost reductions when implementing tire protection systems. Beyond extending tire life, chains reduce unexpected downtime associated with tire failures. Emergency tire replacements often require expensive service calls and extended equipment unavailability. Protection chains transform unpredictable tire maintenance into scheduled, manageable events that align with regular maintenance windows.

Financial analysis reveals compelling return on investment metrics for tire protection systems. While initial chain investment represents a fraction of tire replacement costs, the protective benefits multiply exponentially over time. Organizations tracking operational expenses discover that protection chains pay for themselves within the first few months of deployment. The elimination of emergency service calls alone justifies the investment, particularly in remote locations where tire service availability remains limited and costly.

Comprehensive cost accounting must consider indirect expenses associated with tire failures. Production delays, equipment unavailability, and crew idle time create cascading financial impacts that extend far beyond tire replacement costs. Protection chains mitigate these hidden expenses by maintaining operational continuity and predictable maintenance schedules that support efficient resource allocation.

All-Weather Traction Improvement

Traction challenges plague wheel loader operations across diverse environments and weather conditions. Tire protection chains address these challenges while simultaneously providing protective benefits, creating dual-purpose solutions that enhance both safety and productivity.

Enhanced Grip Mechanisms

The mesh structure of protection chains creates additional contact points between tires and working surfaces. These contact points generate superior grip compared to smooth tire treads, particularly on loose materials, wet surfaces, and inclined terrain. The chain links bite into surface irregularities, providing mechanical advantage that smooth tires cannot achieve. This enhanced traction translates directly into improved productivity and operator confidence.

Seasonal Performance Optimization

Winter operations present unique challenges for wheel loader operators. Ice, snow, and frozen ground create hazardous working conditions that limit equipment effectiveness. Loader tire protection chain systems excel in these conditions, providing reliable traction that enables year-round productivity. The chains break through ice formations and provide grip on packed snow surfaces that would otherwise be treacherous for standard tires.

Fuel Efficiency Improvements

Improved traction directly correlates with reduced fuel consumption. When wheel loaders maintain consistent grip, engines don't work as hard to overcome wheel slip and maintain forward progress. Operators report measurable fuel savings when using protection chains, particularly in challenging terrain where wheel spin would otherwise waste energy. These efficiency gains compound over time, contributing to substantial operational cost reductions.

Advanced traction mechanics demonstrate how protection chains optimize power transfer from engine to ground contact. The mechanical advantage created by chain links engaging surface irregularities reduces the engine load required for equivalent work output. This optimization becomes particularly pronounced during heavy loading cycles, where improved grip eliminates the need for multiple positioning attempts that waste fuel and time.

Environmental benefits accompany fuel efficiency improvements, as reduced consumption translates to lower emissions output. Organizations prioritizing sustainability initiatives find that tire protection chains contribute to environmental goals while simultaneously improving operational economics. The dual benefit of cost savings and environmental responsibility makes protection chains attractive to management teams balancing profitability with corporate responsibility.

Adaptive Environments Application

Modern wheel loader operations span incredibly diverse environments, each presenting unique challenges that demand adaptive solutions. Tire protection chains excel across this broad spectrum of applications, providing consistent performance regardless of operating conditions.

Mining and Quarry Applications

Mining environments represent the ultimate test for tire protection systems. Sharp rock fragments, metal debris, and abrasive surfaces create conditions that would quickly destroy unprotected tires. Protection chains thrive in these harsh environments, enabling continuous operation in areas where standard tires would fail within hours. The chains resist cutting from sharp edges while providing traction on loose aggregate and steep grades common in mining operations.

Construction and Demolition Adaptability

Construction sites present dynamic challenges with constantly changing surface conditions. Concrete debris, rebar fragments, and mixed materials create hazardous conditions for tire integrity. Loader tire protection chain systems adapt to these varied conditions, providing consistent protection whether navigating through demolition debris or working on prepared surfaces. The chains flex with changing terrain while maintaining protective coverage.

Landscaping and Forestry Resilience

Natural environments pose unique challenges, including roots, stumps, and organic debris that can damage unprotected tires. Protection chains excel in these applications, resisting punctures from sharp branches while providing enhanced traction on soft, uneven terrain. Forestry operations particularly benefit from the chains' ability to grip on loose bark, leaves, and muddy conditions that would challenge standard tire treads.

Seasonal variations in natural environments create dynamic operational challenges that protection chains address effectively. Spring mud conditions, autumn leaf accumulation, and winter ice formation each present distinct traction and protection requirements. The adaptability of chain systems ensures consistent performance across these seasonal transitions, maintaining operational continuity when natural conditions would otherwise limit equipment effectiveness.

Waste management operations in outdoor environments benefit significantly from tire protection systems. Landfill operations expose equipment to metal debris, glass fragments, and mixed materials that create severe tire hazards. Protection chains enable continuous operation in these challenging environments while extending tire service life in conditions that would rapidly destroy unprotected rubber. The chains resist punctures from hidden sharp objects while providing reliable traction on unstable surfaces common in waste management facilities.

FAQ

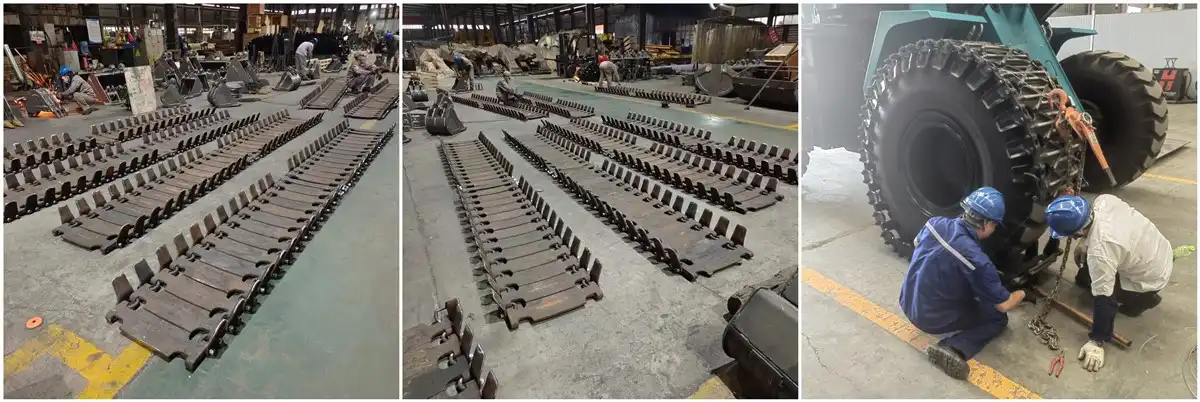

①How long does installation take?

Professional installation typically requires two people approximately one hour to properly fit protection chains to wheel loader tires.

②Do protection chains require ongoing maintenance?

Quality protection chains require minimal maintenance once installed, with few accessories and no regular post-installation upkeep needed.

③What's the typical failure rate?

Well-manufactured protection chains exhibit low failure rates, providing reliable service throughout their operational lifespan.

④Can chains improve fuel efficiency?

Yes, enhanced traction reduces wheel slip, which decreases fuel consumption and saves operational time.

Implementing tire protection solutions represents a strategic investment in operational efficiency and cost control. Quality protection chains deliver measurable benefits, including extended tire life, improved traction, and reduced operational expenses. Tiannuo's loader tire protection chain systems exemplify these advantages, protecting tires while tripling their lifespan through quick installation and minimal maintenance requirements. The enhanced traction boosts efficiency while reducing fuel consumption, creating comprehensive operational improvements that benefit bottom-line performance.

For organizations seeking to optimize wheel loader operations while controlling costs, tire protection chains offer proven solutions across diverse applications. These systems adapt to challenging environments while delivering consistent performance that transforms equipment economics. If you want to learn more about products, please contact us: arm@stnd-machinery.com.

References

- Anderson, M. (2023). "Heavy Equipment Tire Management: Cost Analysis and Protective Strategies." Industrial Equipment Review, 45(3), 78-92.

- Chen, L. & Rodriguez, P. (2022). "Metallurgical Advances in Tire Protection Chain Design." Materials Engineering Quarterly, 18(4), 156-167.

- Thompson, K. (2024). "Operational Efficiency in Mining Equipment: The Role of Tire Protection Systems." Mining Technology Journal, 67(2), 234-248.

- Williams, D. et al. (2023). "Traction Enhancement Technologies for Heavy Construction Equipment." Construction Equipment Monthly, 29(7), 45-58.

- Johnson, R. (2024). "Environmental Adaptability of Wheel Loader Protection Systems." Equipment Management Today, 12(1), 123-135.

About Author: Arm

Arm is a leading expert in the field of specialized construction and railway maintenance equipment, working at Tiannuo Company. Tiannuo specializes in manufacturing a wide range of products, including railway maintenance equipment like railway sleeper changing machines and screening machines, excavator modification equipment such as excavator lifting cabs, various engineering arms for excavators, excavator accessories like digging buckets, and engineering vehicle auxiliary equipment like loader buckets.