What are excavator buckets made of?

Excavator buckets are made from a robust blend of materials designed to withstand the toughest conditions. These essential attachments are primarily crafted from high-strength steel, often combined with wear-resistant alloys to enhance durability. The choice of materials for buckets is crucial, as they must endure constant abrasion, impact, and exposure to various elements while maintaining their shape and efficiency. Understanding the composition of these buckets is key to selecting the right equipment for your project's specific needs.

Materials used in bucket construction

High-strength steel: The backbone of excavator buckets

High-strength steel forms the foundation of most excavator buckets, providing the necessary strength and rigidity to handle heavy loads and resist deformation under pressure. This material is chosen for its exceptional tensile strength and ability to maintain structural integrity even when subjected to extreme forces. Manufacturers often use grades such as ASTM A514 or Hardox 400, known for their superior hardness and resistance to wear.

The use of high-strength steel allows for thinner bucket walls without compromising on strength, resulting in a lighter overall attachment. This weight reduction translates to improved fuel efficiency and increased payload capacity for the excavator. Additionally, the steel's composition is carefully engineered to balance hardness with ductility, ensuring that the bucket can absorb shock without cracking or shattering.

Wear-resistant alloys for enhanced durability

To combat the relentless wear and tear experienced by excavator buckets, manufacturers incorporate wear-resistant alloys into critical areas. These alloys, often containing elements like manganese, chromium, and nickel, are strategically placed on the bucket's cutting edge, side cutters, and wear strips. The addition of these materials significantly extends the bucket's lifespan, reducing downtime and replacement costs.

One popular wear-resistant alloy is Hardox 500, which offers exceptional resistance to abrasive wear while maintaining good weldability. This allows for easy repairs and modifications in the field. Some manufacturers also use overlay plates made from materials like tungsten carbide, which can be welded onto high-wear areas to provide localized protection against extreme abrasion.

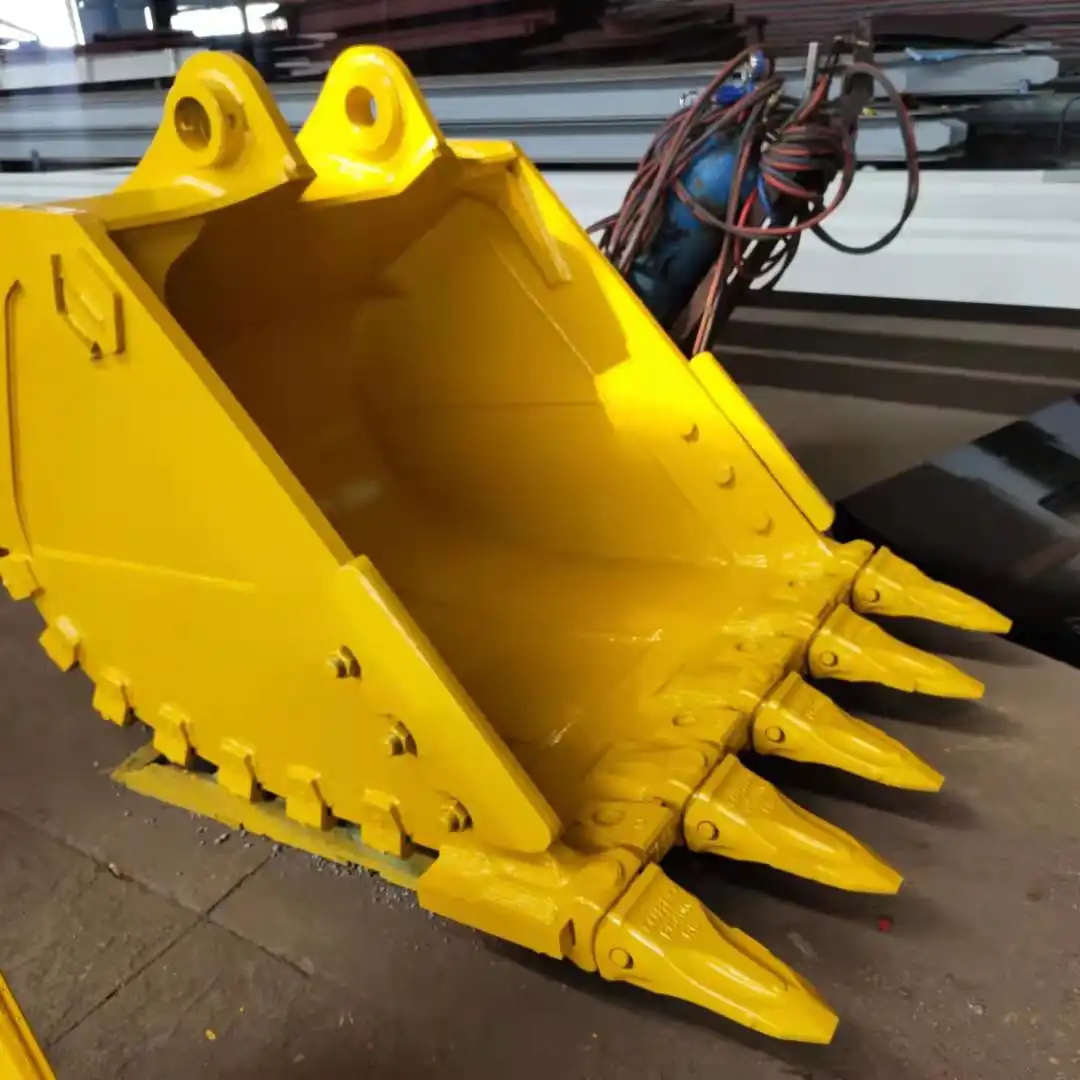

Reinforced edges: Protecting bucket's critical areas

The edges of an excavator bucket are particularly vulnerable to wear and damage. To address this, manufacturers reinforce these areas with additional layers of hardened steel or specialized alloys. The cutting edge, which bears the brunt of the digging force, is often made from a separate piece of high-carbon steel that can be easily replaced when worn.

Side cutters and corner protectors are also reinforced to prevent premature wear and maintain the bucket's overall shape. These components are typically bolted or welded onto the main bucket structure, allowing for easy replacement when necessary. Some advanced designs incorporate reversible or interchangeable wear parts, further extending the bucket's service life and reducing maintenance costs.

Durability Comparison: Steel VS. Alloy Buckets

Steel buckets: Tried-and-true workhorses of construction

Steel buckets have long been the standard in the construction industry, valued for their reliability and cost-effectiveness. These buckets are typically made from high-strength carbon steel, which offers a good balance of durability and affordability. The inherent strength of steel allows these buckets to handle heavy loads and withstand the rigors of daily use on construction sites.

One of the key advantages of steel buckets is their repairability. When damaged, they can often be welded or patched, extending their service life. This versatility makes them a popular choice for general excavation work, where a balance between performance and cost is crucial. Steel buckets also tend to have a lower initial cost compared to their alloy counterparts, making them attractive for budget-conscious projects.

Alloy buckets: Lightweight champions of efficiency

Alloy buckets, often made from materials like aluminum or titanium alloys, represent the cutting edge of excavator bucket technology. These buckets offer significant weight savings compared to traditional steel buckets, sometimes up to 50% lighter. This reduction in weight translates to increased fuel efficiency and the ability to handle larger payloads without exceeding the excavator's lifting capacity.

The use of advanced alloys also provides enhanced resistance to corrosion and wear, particularly in challenging environments such as marine applications or chemical processing plants. Some alloy buckets incorporate composite materials or ceramic coatings to further improve their performance and longevity. While the initial cost of alloy buckets is typically higher, their extended lifespan and improved efficiency can result in long-term cost savings for high-volume operations.

Cost-effectiveness: Balancing price and performance

When evaluating the cost-effectiveness of steel versus alloy buckets, it's essential to consider the total cost of ownership rather than just the initial purchase price. Steel buckets generally have a lower upfront cost and are more economical for short-term projects or applications with moderate wear expectations. They're also more readily available and easier to repair in the field, which can minimize downtime.

Alloy buckets, while more expensive initially, can offer significant long-term savings through reduced fuel consumption, increased productivity, and extended service life. For high-volume operations or specialized applications where weight is a critical factor, the higher cost of alloy buckets may be justified by their superior performance and durability. Ultimately, the choice between steel and alloy buckets depends on the specific requirements of the project, the operating environment, and the expected return on investment.

Innovative Materials Shaping Future Buckets

Carbon fiber buckets: Strength meets lightweight design

The construction industry is witnessing a revolutionary shift with the introduction of carbon fiber excavator buckets. These cutting-edge attachments combine the strength of traditional materials with the lightweight properties of advanced composites. Carbon fiber's exceptional strength-to-weight ratio allows for the creation of buckets that are up to 75% lighter than their steel counterparts while maintaining comparable durability.

This dramatic weight reduction translates to increased fuel efficiency and the ability to handle larger payloads without compromising the excavator's stability or lifting capacity. Carbon fiber buckets also exhibit superior resistance to corrosion and fatigue, potentially extending their operational lifespan beyond that of conventional materials. While the initial cost of carbon fiber buckets is significantly higher, their potential for long-term cost savings and performance improvements makes them an attractive option for forward-thinking construction firms.

Nano-enhanced materials: Pushing durability boundaries

Nanotechnology is making its mark on excavator bucket design, with manufacturers incorporating nano-enhanced materials to push the boundaries of durability and performance. By manipulating materials at the molecular level, engineers can create buckets with unprecedented wear resistance and strength. Nano-coatings applied to bucket surfaces can dramatically reduce friction and prevent material buildup, improving efficiency and reducing maintenance needs.

Some innovative designs incorporate self-healing nano-materials that can automatically repair minor cracks and scratches, potentially extending the bucket's lifespan and reducing downtime. While still in the early stages of development, these nano-enhanced buckets show promise for applications in highly abrasive environments or where minimal maintenance is crucial.

The materials used in excavator buckets play a crucial role in their performance, durability, and efficiency. From high-strength steel to advanced alloys and innovative composites, the evolution of bucket materials reflects the industry's drive for improved productivity and sustainability. As construction projects become more demanding and diverse, the choice of bucket material becomes increasingly important. By understanding the properties and benefits of different materials, construction professionals can make informed decisions that optimize their operations and contribute to project success.

FAQ

①How often should excavator buckets be replaced?

The lifespan of an excavator bucket varies depending on usage and material. Generally, buckets should be inspected regularly and replaced when wear exceeds 50% of the original thickness or if structural integrity is compromised.

②Can excavator buckets be repaired instead of replaced?

Yes, many excavator buckets can be repaired through welding, reinforcing, or replacing worn parts. However, extensive damage may make replacement more cost-effective.

③Are there specialized buckets for different types of soil?

Absolutely. Manufacturers offer various bucket designs optimized for different soil types, from soft clay to hard rock. Choosing the right bucket can significantly improve excavation efficiency.

④How do titanium alloy buckets compare to steel in terms of durability?

Titanium alloy buckets often offer superior durability and corrosion resistance compared to steel, with the added benefit of being lighter. However, they typically come at a higher initial cost.

⑤What safety features are incorporated into modern excavator bucket designs?

Modern buckets often include safety features such as lifting eyes for secure attachment, anti-spillage designs to prevent material fallback, and compatibility with quick-coupler systems for safe and efficient bucket changes.

Where to Buy Excavator Buckets?

Tiannuo Machinery offers a wide range of excavator accessories, including digging buckets, rock buckets, and specialized attachments for various applications. Our products are designed to enhance your excavator's performance and efficiency across multiple industries, from construction and mining to landscaping and waste management. We also provide customized solutions to meet your specific project requirements. For expert advice on selecting the right excavator bucket for your needs or to inquire about our product range, contact us at rich@stnd-machinery.com. Our team is ready to assist you in finding the perfect attachment to boost your productivity and streamline your operations.

References

- Construction Equipment Magazine: "Excavator Bucket Materials"

- Journal of Construction Engineering: "Advancements in Bucket Technology"

- TianNuo Machinery Official Website: "Excavator Bucket Specifications"

- Engineering News-Record: "Future of Excavator Attachments"

- Mining Technology: "Innovations in Bucket Materials for Heavy-Duty Applications"

- American Society of Mechanical Engineers: "Smart Buckets in Construction"

About Author: Arm

Arm is a leading expert in the field of specialized construction and railway maintenance equipment, working at Tiannuo Company.