What are the different types of excavator rail clamps?

Railway maintenance professionals rely on specialized equipment to ensure safe and efficient operations, and understanding the different types of excavator rail clamp systems available can significantly impact project success. These essential attachments fall into three primary categories: hydraulic, manual, and customizable clamps, each designed to meet specific operational requirements and project constraints.

Hydraulic rail clamps leverage your excavator's existing hydraulic system to provide powerful, consistent clamping force with precise control capabilities. Manual clamps offer straightforward operation without hydraulic dependency, making them ideal for backup situations or projects with limited hydraulic capacity. Customizable options address unique project specifications, accommodating various rail gauges, mounting configurations, and specialized operational requirements that standard clamps cannot fulfill.

The choice between these rail clamp types depends on several factors including project scope, available equipment, budget considerations, and specific railway maintenance requirements. Understanding these distinctions helps procurement managers, engineers, and project supervisors make informed decisions that optimize both safety and operational efficiency while maintaining cost-effective project execution.

Hydraulic Rail Clamps

Hydraulic excavator rail clamp systems represent the most advanced and powerful option available for railway maintenance operations. These sophisticated attachments integrate seamlessly with your excavator's existing hydraulic infrastructure, delivering consistent clamping forces up to 30 kN while maintaining precise operational control throughout demanding work cycles.

Advanced Hydraulic Integration Technology

Modern hydraulic rail clamps connect directly to your excavator's hydraulic system through specialized quick-connect fittings that minimize installation time and maximize operational efficiency. The integrated control systems allow operators to adjust clamping pressure dynamically, responding to varying load conditions and track configurations without interrupting workflow. These systems typically operate within 16-21 MPa pressure ranges, providing sufficient force for heavy-duty applications while maintaining safety margins.

The hydraulic power delivery system ensures consistent performance regardless of environmental conditions or operator fatigue. Unlike manual alternatives, hydraulic clamps maintain steady pressure throughout extended operations, reducing the risk of equipment slippage during critical lifting or positioning tasks. This reliability proves particularly valuable during complex railway maintenance projects where precision and safety cannot be compromised.

Enhanced Safety and Control Features

Safety mechanisms built into hydraulic rail clamps include pressure hold valves that maintain clamping force even during hydraulic system fluctuations or temporary power interruptions. Locking pins provide mechanical backup security, ensuring equipment remains securely attached to rails regardless of hydraulic system status. These redundant safety systems meet stringent railway industry standards while providing operators with confidence during high-risk operations.

The precise control capabilities of hydraulic systems allow operators to engage and disengage clamps gradually, reducing shock loads on both the equipment and railway infrastructure. This controlled operation extends equipment lifespan while minimizing track damage during maintenance activities. Operators can fine-tune clamping pressure based on specific rail conditions, load requirements, and environmental factors.

Operational Efficiency and Performance Benefits

Hydraulic rail clamps significantly reduce setup and positioning time compared to manual alternatives, allowing crews to complete more work within scheduled maintenance windows. The rapid engagement and release capabilities enable efficient movement between work locations, maximizing productive time while minimizing track occupation periods that disrupt regular railway operations.

These systems excel in applications requiring frequent repositioning, heavy lifting, or precise equipment placement. The consistent clamping force eliminates variables associated with manual operation, ensuring repeatable results across different operators and work conditions. This consistency proves particularly valuable for projects requiring precise measurements or standardized procedures.

Manual Rail Clamps

Manual rail clamp systems provide reliable, straightforward operation without dependency on hydraulic power systems, making them invaluable for specific applications where simplicity, cost-effectiveness, or hydraulic independence takes priority over automated convenience.

Mechanical Reliability and Independence

Manual excavator rail clamp mechanisms rely on robust mechanical systems that operate independently of hydraulic power, electrical systems, or complex control interfaces. These clamps typically feature lever-actuated or threaded adjustment mechanisms that provide reliable clamping force through direct mechanical advantage. The absence of hydraulic components eliminates potential failure points associated with seals, hoses, and pressure systems.

The mechanical simplicity of manual clamps makes them particularly suitable for remote locations where hydraulic service support may be limited or unavailable. Maintenance requirements remain minimal, typically involving periodic lubrication and basic mechanical adjustments that field personnel can perform without specialized training or equipment. This independence proves valuable for emergency situations or backup applications where reliability outweighs convenience.

Cost-Effective Solutions for Budget-Conscious Projects

Manual rail clamps offer significant cost advantages for projects with limited budgets or infrequent usage requirements. The initial investment remains substantially lower than hydraulic alternatives, while ongoing maintenance costs stay minimal due to the absence of complex hydraulic components. These economic benefits make manual clamps attractive for smaller contractors, occasional-use applications, or projects where equipment cost represents a significant budget consideration.

The straightforward design translates to longer service life with proper maintenance, providing excellent return on investment for appropriate applications. Replacement parts remain readily available and affordable, while repairs can often be completed using standard mechanical tools and techniques. This economic accessibility makes manual clamps viable for operations that might otherwise forgo rail clamp technology due to cost constraints.

Specialized Applications and Use Cases

Manual rail clamps excel in applications where hydraulic power may be unavailable, impractical, or unnecessary for the intended operation. Emergency repair situations often require equipment that can function independently of complex systems, making manual clamps valuable for crisis response teams and emergency maintenance crews. These clamps also serve as excellent backup systems for operations that primarily rely on hydraulic equipment.

Lighter-duty applications that don't require maximum clamping force may find manual systems perfectly adequate while avoiding the complexity and cost of hydraulic alternatives. Training and certification requirements remain minimal for manual systems, allowing crews to deploy these tools quickly without extensive specialized training programs. This accessibility proves particularly valuable for organizations with high personnel turnover or limited training resources.

Customizable Rail Clamps

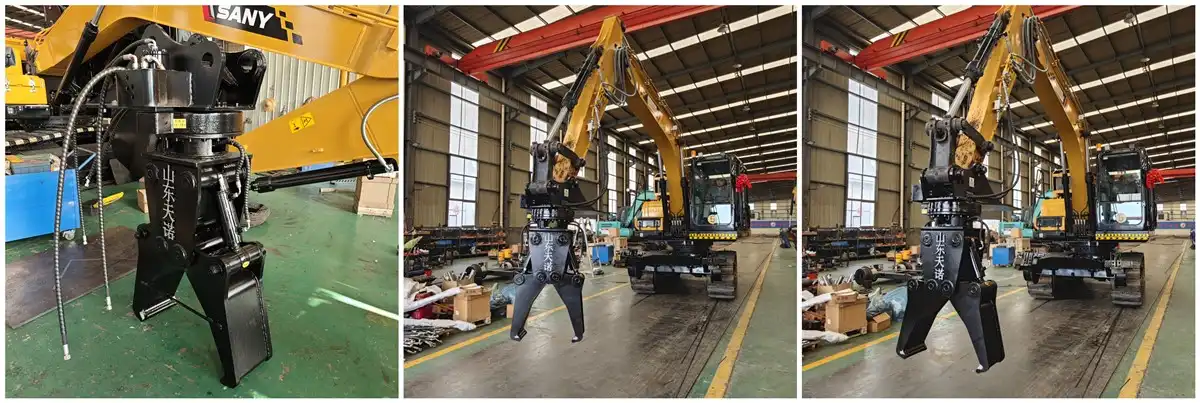

Customizable rail clamp solutions address unique project requirements that standard equipment cannot accommodate, providing tailored engineering solutions for specialized applications, unusual rail configurations, or specific operational demands that require bespoke equipment design and manufacturing.

Engineering Solutions for Unique Rail Configurations

Railway systems worldwide utilize various rail gauges, profiles, and mounting configurations that may not align with standard excavator rail clamp designs. Customizable clamps address these challenges through engineering consultation and design modification processes that adapt clamping mechanisms to specific track specifications. Standard rail gauge compatibility typically covers 1435mm configurations, but custom solutions can accommodate 1520mm, 1000mm, 1067mm, and other regional specifications.

The customization process begins with detailed analysis of existing rail infrastructure, operational requirements, and safety considerations specific to each project. Engineering teams work closely with clients to understand load requirements, environmental conditions, and operational constraints that influence design parameters. This collaborative approach ensures final products meet exact specifications while maintaining safety standards and operational efficiency.

Advanced manufacturing capabilities enable modification of clamp geometry, mounting interfaces, and control systems to match specific excavator models and operational requirements. Custom brackets and mounting solutions accommodate various excavator chassis configurations, ensuring secure attachment regardless of equipment manufacturer or model variations.

Specialized Industry Applications

Different industries present unique challenges that require specialized rail clamp solutions beyond standard railway maintenance applications. Mining operations may require enhanced corrosion resistance, increased load capacity, or specialized mounting configurations for underground or harsh environmental conditions. Construction projects involving temporary rail systems may need quick-release mechanisms or portable mounting solutions that standard clamps cannot provide.

Waste management and environmental cleanup operations often encounter contaminated environments where specialized coatings or materials become necessary to prevent equipment degradation. Custom solutions can incorporate enhanced surface treatments, specialized sealing systems, or materials specifically chosen for chemical resistance and extended service life in challenging conditions.

Port and logistics operations may require clamps designed for container handling applications or specialized cargo movement systems that operate on rail infrastructure. These applications often demand higher load capacities, specialized control interfaces, or integration with existing material handling systems that require custom engineering solutions.

OEM and Design Consultation Services

Original Equipment Manufacturer (OEM) support ensures customized rail clamps integrate seamlessly with existing equipment while maintaining warranty coverage and service support. Design consultation services provide expert guidance throughout the specification and selection process, helping clients identify optimal solutions for their specific requirements while avoiding common pitfalls associated with equipment modification or adaptation.

The consultation process includes site assessment, operational analysis, and engineering review to ensure proposed solutions address all relevant factors including safety, efficiency, maintenance requirements, and regulatory compliance. This comprehensive approach minimizes project risks while maximizing equipment performance and service life.

Custom manufacturing capabilities support both prototype development and production quantities, allowing clients to test solutions before committing to full-scale implementation. This flexibility proves particularly valuable for innovative applications or situations where standard solutions may not fully address operational requirements.

FAQ

①What factors should I consider when choosing between hydraulic and manual rail clamps?

Consider your project's hydraulic capacity, frequency of use, budget constraints, and operational requirements. Hydraulic clamps offer superior convenience and power but require hydraulic system integration. Manual clamps provide reliability and cost-effectiveness but may require more physical effort during operation.

②Can custom rail clamps accommodate non-standard rail gauges?

Yes, customizable excavator rail clamp solutions can be engineered for virtually any rail gauge specification, including regional standards like 1520mm, 1000mm, or 1067mm configurations. Custom design processes ensure proper fit and safe operation regardless of track specifications.

③How long does it take to manufacture custom rail clamps?

Custom rail clamp manufacturing typically requires 7-20 working days depending on complexity and customization requirements. Complex engineering modifications may require additional time for design verification and testing before production begins.

④What maintenance is required for different types of rail clamps?

Hydraulic clamps require periodic hydraulic system inspection, seal replacement, and pressure testing. Manual clamps need basic lubrication and mechanical adjustment. All types benefit from regular cleaning and visual inspection for wear or damage.

⑤Do rail clamps work with all excavator brands?

Rail clamps can be adapted to work with most excavator brands through custom mounting brackets and interface modifications. Compatibility depends on hydraulic capacity, mounting points, and control system integration requirements specific to each excavator model.

Understanding the different types of excavator rail clamps empowers railway maintenance professionals to select optimal equipment for their specific operational requirements. Whether your projects demand the power and precision of hydraulic systems, the reliability and cost-effectiveness of manual operation, or the specialized capabilities of custom solutions, choosing the right rail clamp technology ensures safe, efficient, and successful railway maintenance operations.

Tiannuo Machinery offers comprehensive rail clamp solutions featuring high-strength alloy steel construction, customizable hydraulic and manual configurations, and OEM support for specialized applications. Our products accommodate standard 1435mm rail gauges and custom specifications, delivering up to 30 kN clamping force with integrated safety features including locking pins and pressure hold valves. For detailed specifications and consultation regarding your rail clamp requirements, contact our engineering team at arm@stnd-machinery.com to discuss how our solutions can optimize your railway maintenance operations.

References

- Railway Engineering and Maintenance Standards Manual, International Railway Safety Association, Chapter 12: Mobile Equipment and Attachments

- Hydraulic Systems in Railway Maintenance Equipment: Design Principles and Safety Considerations, Journal of Railway Engineering Technology, Volume 45

- Cost-Benefit Analysis of Manual versus Automated Rail Maintenance Equipment, Railway Economics Quarterly, Issue 3

- Custom Engineering Solutions for Specialized Railway Applications, Proceedings of the International Railway Equipment Conference

- Safety Standards and Operational Guidelines for Excavator Rail Attachments, Railway Safety Commission Technical Publication Series

About Author: Arm

Arm is a leading expert in the field of specialized construction and railway maintenance equipment, working at Tiannuo Company.