What is a railway track sweeper used for?

A railway track sweeper serves as an essential piece of maintenance equipment designed to keep railway lines clean, safe, and operational. These specialized machines remove debris, dirt, ballast fragments, and other obstructions from rail tracks, ensuring smooth train operations and preventing costly delays. These sweepers come in various configurations, from hydraulic-powered attachments for excavators to dedicated self-propelled units, each engineered to tackle specific cleaning challenges along railway corridors.

The primary purpose of a track sweeper extends beyond simple cleaning; it plays a crucial role in maintaining track geometry, preventing derailments, and extending the lifespan of railway infrastructure. Modern track sweepers utilize advanced brush systems, vacuum technology, and hydraulic controls to efficiently remove everything from accumulated sand and gravel to vegetation and man-made debris that could compromise track integrity and train safety.

Removing Debris and Obstructions

Clearing Natural Debris

Railway networks constantly face challenges from natural debris accumulation, particularly in areas with heavy vegetation or seasonal weather patterns. Leaves, branches, sand, and organic matter can quickly build up on tracks, creating hazardous conditions for train operations. A well-maintained railway track sweeper efficiently removes these materials before they cause traction problems or signal interference. The specialized brush systems rotate at optimal speeds to dislodge stubborn debris while preserving the ballast bed's integrity.

Seasonal challenges require different approaches to debris management. During autumn months, fallen leaves create slippery conditions that can affect braking performance and wheel adhesion. Winter operations demand removal of snow, ice, and sand that accumulates from weather events and traction sanders. Spring cleanup involves clearing vegetation growth and winter debris, while summer maintenance focuses on dust control and ballast cleaning. Track sweepers equipped with adjustable brush angles and variable rotation speeds can adapt to these changing conditions effectively.

Eliminating Industrial Contamination

Industrial railway operations generate unique contamination challenges that require specialized cleaning approaches. Coal dust, mineral spillage, chemical residues, and metal shavings can accumulate along tracks, creating environmental hazards and operational difficulties. Track sweepers designed for industrial applications feature enhanced filtration systems and containment capabilities to safely collect and dispose of hazardous materials.

The effectiveness of debris removal directly impacts operational efficiency and safety standards. Contaminated tracks can cause wheel slip, reduced braking effectiveness, and accelerated wear on rolling stock components. Regular sweeping operations using properly calibrated equipment prevent these issues while maintaining compliance with environmental regulations. Modern track sweepers incorporate vacuum systems that capture fine particles and prevent airborne contamination during cleaning operations.

Managing Ballast Displacement

Ballast stones naturally migrate and shift during train operations, creating uneven surfaces and potential safety hazards. Track sweepers equipped with ballast management capabilities can redistribute displaced stones, remove fouled ballast, and maintain proper drainage patterns. This process requires precision to avoid disrupting track geometry while ensuring adequate ballast support for rail stability.

The relationship between ballast condition and track performance cannot be overstated. Clean, well-distributed ballast provides essential support for railway ties and rails while facilitating proper drainage. Contaminated or displaced ballast compromises track stability and can lead to costly maintenance issues. Effective sweeping operations maintain ballast cleanliness and prevent the accumulation of fine particles that reduce drainage efficiency.

Maintaining Track Geometry and Functionality

Preserving Rail Alignment

Track geometry maintenance represents one of the most critical functions of railway infrastructure management. Accumulated debris and contamination can gradually alter track alignment, affecting train stability and passenger comfort. Railway track sweepers contribute to geometry preservation by removing materials that could interfere with track positioning equipment and measurement systems. Clean tracks allow for accurate geometry assessments and timely corrective actions.

The precision required for modern railway operations demands consistent track geometry within tight tolerances. Even minor deviations can result in increased wear on rolling stock, reduced operating speeds, and potential safety concerns. Regular sweeping operations support geometry maintenance programs by ensuring clear access for measurement equipment and preventing debris-related distortions in track positioning.

Optimizing Drainage Systems

Effective drainage remains fundamental to railway track longevity and performance. Debris accumulation can block drainage channels, create standing water, and accelerate track deterioration. Track sweepers equipped with specialized brushes and vacuum systems can clear drainage paths and maintain proper water flow patterns. This preventive maintenance approach reduces the risk of frost damage, ballast contamination, and subgrade instability.

Water management challenges intensify during extreme weather events, making drainage maintenance even more critical. Clogged drainage systems can lead to track flooding, service disruptions, and expensive emergency repairs. Proactive sweeping operations help maintain drainage capacity and prevent water-related infrastructure damage. Modern track sweepers can adapt their cleaning patterns to focus on drainage areas while preserving surrounding ballast integrity.

Supporting Signal and Communication Systems

Railway signaling and communication equipment requires clean, unobstructed environments to function reliably. Debris accumulation around signal equipment, track circuits, and communication cables can cause system malfunctions and safety hazards. Track sweepers designed for comprehensive cleaning can maintain clear zones around critical infrastructure components, ensuring reliable system operation.

The integration of advanced technology in modern railway systems increases the importance of maintaining clean operating environments. Debris interference with electronic systems can result in false signals, communication failures, and operational delays. Regular sweeping operations using equipment calibrated for precision cleaning help prevent technology-related disruptions while maintaining system reliability.

Supporting Railway Infrastructure Longevity

Preventing Accelerated Wear

Infrastructure longevity depends heavily on preventing accelerated wear caused by debris accumulation and contamination. Abrasive materials on tracks can cause premature rail wear, while debris buildup accelerates component deterioration. Railway track sweepers play a vital role in extending infrastructure lifespan by maintaining clean operating conditions and reducing wear-inducing contaminants.

The economic impact of premature infrastructure replacement can be substantial, making preventive maintenance through regular sweeping operations a cost-effective investment. Clean tracks reduce maintenance frequency, extend component life, and minimize unexpected failures. Track sweepers equipped with adjustable cleaning intensities can provide appropriate maintenance levels for different track sections and usage patterns.

Enhancing Inspection Capabilities

Comprehensive track inspection requires clear visibility of all infrastructure components. Debris accumulation can obscure potential problems, delaying identification of maintenance needs and increasing repair costs. Regular sweeping operations ensure that inspection teams can accurately assess track conditions and identify developing issues before they become critical.

Modern inspection technologies, including automated systems and advanced imaging equipment, require clean operating environments to function effectively. Debris interference can compromise inspection accuracy and lead to missed defects. Track sweepers that maintain consistent cleanliness levels support comprehensive inspection programs and improve overall infrastructure management.

Extending Maintenance Intervals

Proactive debris management through regular sweeping operations can significantly extend maintenance intervals for various railway components. Clean tracks experience less wear, require fewer emergency repairs, and maintain better overall condition. This approach reduces lifecycle costs while improving service reliability and operational efficiency.

The relationship between cleanliness and maintenance frequency becomes particularly important for high-traffic rail corridors. Intensive use generates more debris and contamination, requiring enhanced cleaning protocols to maintain acceptable condition levels. Strategic sweeping programs can optimize maintenance schedules while ensuring safe and reliable operations.

FAQ

①How often should railway tracks be swept?

Sweeping frequency depends on traffic volume, environmental conditions, and operational requirements. High-traffic corridors typically require weekly sweeping, while lighter-use lines may need monthly attention. Seasonal factors and local conditions can influence optimal schedules.

②What types of debris can track sweepers handle?

Modern track sweepers can remove leaves, sand, ballast fragments, metal shavings, vegetation, snow, and various industrial contaminants. Equipment selection depends on specific debris types and environmental conditions.

③Are track sweepers compatible with different track gauges?

Quality track sweepers are designed for multiple gauge compatibility, including standard gauge (1435mm), broad gauge (1520mm), and narrow gauge (1067mm) systems. Adjustable configurations accommodate various track specifications.

④How do track sweepers affect train operations?

Track sweepers typically operate during maintenance windows to minimize operational disruption. Some units can work alongside reduced train schedules, while others require complete track possession for safety and efficiency.

⑤What maintenance do track sweepers require?

Regular maintenance includes brush replacement, hydraulic system servicing, and component inspections. Proper maintenance ensures optimal performance and extends equipment lifespan while maintaining safety standards.

Railway track maintenance represents a critical investment in transportation infrastructure safety and efficiency. Modern railway track sweepers provide essential services that extend beyond simple cleaning, supporting comprehensive maintenance programs that preserve track geometry, enhance drainage systems, and promote infrastructure longevity. The integration of advanced technology and specialized equipment ensures that railway operators can maintain safe, reliable service while optimizing maintenance costs and operational efficiency. Professional maintenance teams understand that effective debris management through regular sweeping operations forms the foundation of successful railway infrastructure management, preventing costly repairs while ensuring passenger and freight operations continue without disruption.

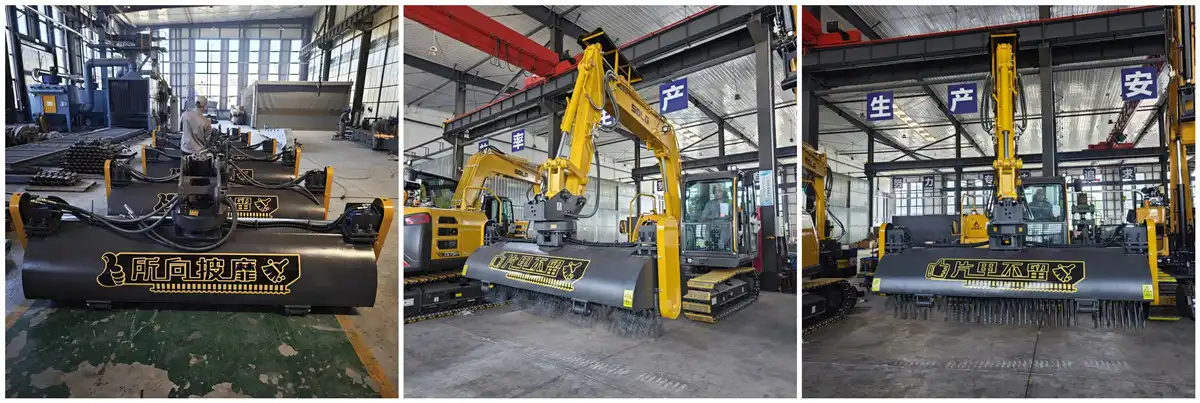

For railway operators seeking reliable track maintenance solutions, Tiannuo's Railway Track Sweeper offers comprehensive cleaning capabilities suitable for excavators ranging from 7-15 tons. With compatibility across multiple track gauges (1435/1520/1067mm) and featuring 360-degree rotation capability, this equipment provides the versatility and performance needed for effective track maintenance operations. The unit's 2600mm working width and robust construction ensure efficient debris removal while maintaining the precision required for modern railway operations. To learn more about how our track sweeper solutions can enhance your maintenance programs, contact us at boom@stnd-machinery.com.

References

- Railway Engineering and Maintenance Handbook: Modern Approaches to Track Infrastructure Management, International Railway Association, 2024

- Ballast Maintenance and Track Geometry Preservation: Best Practices for Railway Operations, Journal of Transportation Engineering, Volume 48, 2023

- Debris Management in Railway Systems: Environmental and Safety Considerations, Railway Safety and Standards Board, 2024

- Advanced Track Maintenance Equipment: Technology and Applications, International Conference on Railway Engineering, 2023

- Cost-Effective Railway Infrastructure Management: Preventive Maintenance Strategies, Transportation Research Record, Issue 2785, 2024

About Author: Arm

Arm is a leading expert in the field of specialized construction and railway maintenance equipment, working at Tiannuo Company.