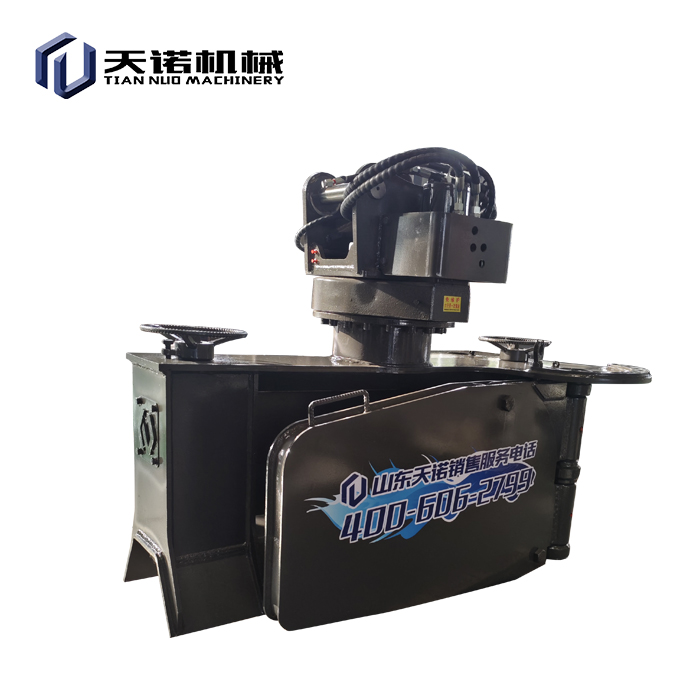

railway double-head tamper

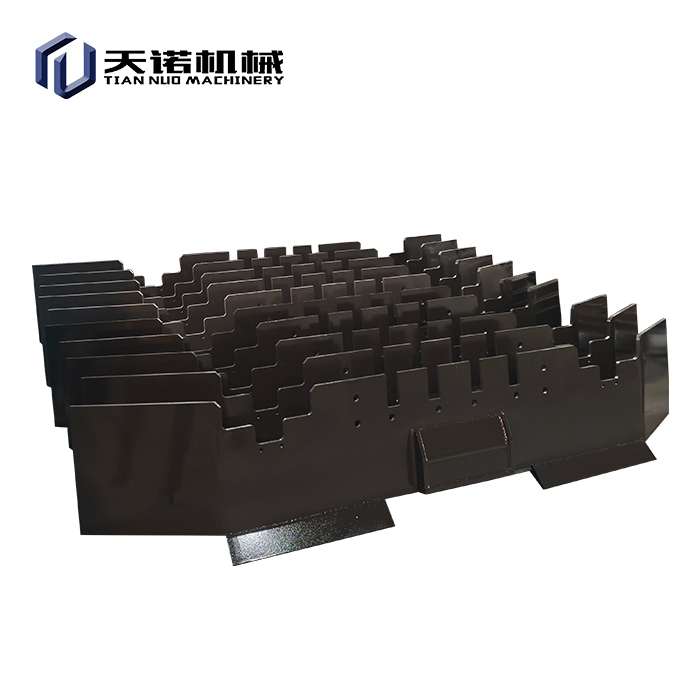

Number of tampers: 8

Taming depth: 400mm

Rotation angle: 360°

Taming distance: 460mm

Clamping range: 390mm-625mm

Maximum torque: 356Nm

Motor rated pressure: 400bar

- Product Description

Our main product portfolio includes railway construction and maintenance equipment, customized engineering robotic arms, customized attachments, and auxiliary equipment for engineering vehicles. Our business network covers multiple countries and regions worldwide. We always adhere to the business philosophy of "quality first, customer foremost" and are committed to providing customers with cost-effective products and efficient full-cycle service support, continuously driving industry development through technological innovation.

What is a double-head tamping machine?

A double-head tamping machine is a specialized engineering machine used for railway track maintenance. Its core feature is that it is equipped with two tamping units that can operate synchronously and independently. Using a pair of tamping picks (or tamping plates) on the two tamping heads, it compacts the ballast (crushed stone) under and on both sides of the railway sleepers by means of high-frequency vibration and clamping.

| NO. | Name | Unit | |

| 1 | Applicable excavator tonnage | ton | RRE15WP |

| 2 | Applicable track gauge | MM | 1520、1435、1067、1676 |

| 3 | Vibration frequency | HZ | 40 |

| 4 | Rotation angle | ° | 360 |

| 5 | Number of pickaxes | pcs | 8 |

| 6 | Maximum tamping depth | mm | 380 |

| 7 | Clamping range | mm | 380-625 |

| 8 | Maximum motor speed | r/min | 5000 |

| 9 | Motor displacement | ml/r | 56 |

| 10 | Motor rated pressure | bar | 400 |

Main Applications and Features:

High Efficiency: Processes two sleepers in a single cycle, making it ideal for large-scale railway maintenance, especially major track overhauls and centralized maintenance.

High Precision: Synchronous control technology ensures uniform track lifting and ballast compaction, accurately restoring track design parameters.

Strong Adaptability:

Can be used as an attachment for excavators (similar to a bucket or hydraulic hammer), mounted on ordinary excavators or dual-purpose road-rail excavators, offering high mobility and flexibility.

Can also be used as an independent device with its own power and running gear.

Suitable for straight sections; by adjusting or equipping with a special rotating device, it can also handle curved sections.

Improved Quality: By uniformly compacting the ballast bed, it significantly enhances the longitudinal and lateral resistance of the track, thereby improving the overall stability and load-bearing capacity of the track and extending maintenance cycles.

In short, the double-headed tamping machine is like a "specialized massager" for railway tracks, working in two directions to quickly and evenly compact the track foundation, making it an indispensable key piece of equipment in modern, high-efficiency railway maintenance operations.

Core Function: Utilizing paired tamping picks (or tamping plates) on two tamping heads, high-frequency vibration and clamping are used to compact the ballast (crushed stone) under and on both sides of the railway sleepers.

Core Advantage: It can simultaneously compact the track bed under two adjacent sleepers. Compared to traditional single-head tamping machines, this significantly improves work efficiency and avoids the time wasted on repetitive single-point positioning.

Key Technology: Equipped with a sophisticated hydraulic and electronic control system, it ensures that the insertion depth, vibration frequency, and clamping force of the two tamping heads are highly consistent. This is crucial for ensuring that the track geometry (such as gauge, level, and elevation) is uniform and smooth after tamping, directly affecting the safety and comfort of train operation.

The double-headed tamping machine, connected to an excavator, utilizes its hydraulic system to drive three core actions in precise coordination to complete the sleeper tamping operation. Its work cycle can be broken down into the following four key steps:

Step 1: Positioning and Insertion

Under the control of the excavator arm, the tamping machine moves above two adjacent sleepers. The hydraulic system drives the tamping arm, causing two pairs of tamping picks (commonly known as "pick hands") to vertically insert into the ballast from both sides of the sleepers until the preset tamping depth is reached.

Step 2: Vibration and Compaction

After the tamping picks are inserted, the built-in hydraulic vibrator activates, generating high-frequency vibration. This vibration effectively reduces the friction between ballast particles, causing the crushed stone to rearrange under the action of gravity and vibration, flowing towards the bottom of the sleepers and into the gaps, laying the foundation for initial compaction.

Step 3: Clamping and Tamping

This is the core action to ensure tamping quality. While vibrating continuously, the two pairs of tamping picks, driven by hydraulic cylinders, move towards each other, performing a clamping action. This action, like a pair of "mechanical hands," tightly squeezes and compacts the ballast at the bottom and sides of the sleepers, forming a stable supporting foundation.

Step Four: Lifting and Relocation After the clamping action is completed, the vibration stops. The tamping pick first opens, separating from the compacted ballast, and then the excavator arm lifts it as a whole. Subsequently, the excavator can operate the tamping machine to rotate, adjusting to the next working angle or position, preparing for the next pair of sleepers.

Key Points: The efficiency of the entire process relies on three independent hydraulic circuits provided by the excavator, which precisely control the three core functions of vibration, clamping, and rotation. This multi-action coordinated working mode ensures that the ballast is compacted quickly, evenly, and with high strength, thereby efficiently restoring and maintaining the smoothness and stability of the track in the long term.

Q: How efficient is the Double-Ended Tamping Machine compared to single-head models?

A: With its dual tamping units working simultaneously, it can process two sleepers in one cycle, significantly increasing work efficiency and reducing track occupation time.

Q: Is specialized training required to operate the machine?

A: Thanks to its intuitive control system, operators can master basic operations after a short training session, typically within a single working day.

Q: Can it be used on curved sections of track?

A: Yes. The design allows for flexible adjustment of the tamping heads, enabling effective operation on both straight tracks and small-radius curves.

Q: How is the machine powered and installed?

A: It can be mounted as an attachment to compatible excavators or rail-bound carriers via a standard quick-coupler interface, with hydraulic power supplied directly by the host machine.

Q: What kind of maintenance does it require?

A: Designed for rugged use, it only needs regular lubrication, inspection of wear parts such as tamping tools, and periodic system checks to ensure reliable long-term performance.

Q: Does it ensure consistent tamping quality?

A: Absolutely. The synchronized control system ensures uniform vibration frequency, penetration depth, and clamping force across both tamping heads, guaranteeing even and stable track geometry restoration.

Contact Us

Are you ready to enhance your railway maintenance operations with Tiannuo Machinery’s railway double-head tamper? Contact us today to discuss your specific requirements and receive a tailored solution that meets your needs.

Email:arm@stnd-machinery.com

_1766390709841.webp)

(1)_1766390709859.webp)