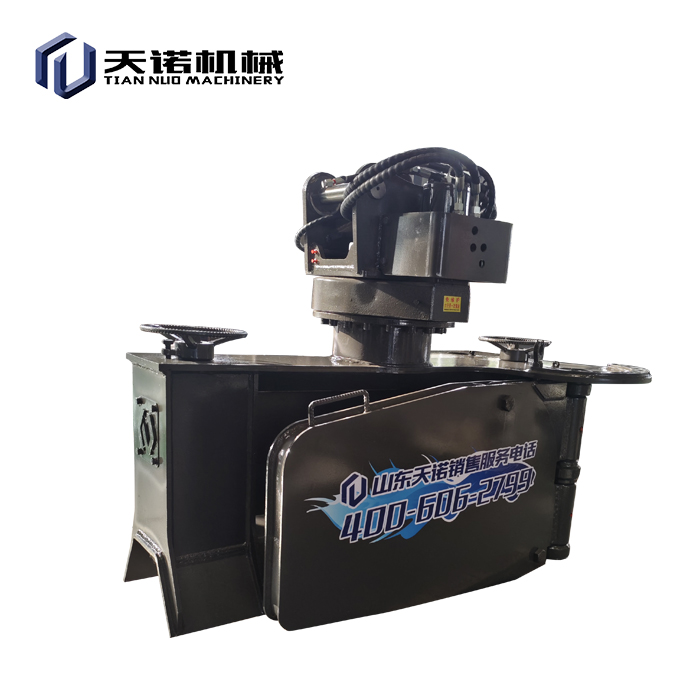

Hi-Rail Excavator

Two-Wheel Drive: Chassis equipped with track wheels, speed can reach 15 km/h

Positioning Mode: Chassis equipped with track limit wheels to prevent the machine from derailing

Applicable Track Gauge: 1435/1520 mm

Number of Drive Wheels: 2

Drive Type: Hydraulic drive (two-wheel drive)

Motor Type: Integrated plunger motor

Track Wheel Material: Forged

Sleeper Clamp Opening: < 650 mm

Rotation Angle: 360°

Large Plate Width: 2800 mm

Walking Range: Normal road surface, railway line

Railway Track Running Speed (Powered Wheel): 10-15 km/h

Railway Operation Running Speed (Free Wheel): 2.86-5.0 km/h

- Product Description

Tiannuo Machinery has been at the forefront of the railway construction and maintenance industry for over 10 years. As a leading manufacturer of specialized equipment, we are dedicated to providing innovative and reliable solutions for Hi-Rail Excavator . Our experience and expertise have earned us a reputation as a trusted partner for railway companies, construction contractors, government agencies, and logistics enterprises. We pride ourselves on our ability to deliver high-quality products with fast delivery and comprehensive support, ensuring that our customers can depend on us for their most critical projects.

Introduction

A hi-rail excavator, is a specialized construction machine

designed to work efficiently on railway tracks. Unlike standard crawler or wheel excavators, a railway excavator is equipped

with a hi-rail system—a set of rail wheels that allow the machine to travel safely and steadily on rails.

Railway excavators are widely used for track maintenance, rail construction, ballast handling, sleeper replacement, ditch cleaning,

and emergency repair tasks. Thanks to their versatility, they can switch quickly between road mode and rail mode, making them

essential equipment for modern railway maintenance teams.

| Model | E675Ht |

| Weight | 10500KG |

| Power | 53.7KW/73HP |

| Engine brand | Yanmar |

| Emission stage | CHINA IV |

| Applicable gauge | 1435mm/1520mm |

| Driving type on railway | Driving wheel |

| Working type on railway | Crawler+ Guide wheel |

| Driving speed | Driving type |

| Motor type | Cycloid motor / plunger motor |

| Wheel diameter | 410*346mm |

| Transportation size | 6500*2260*2620mm |

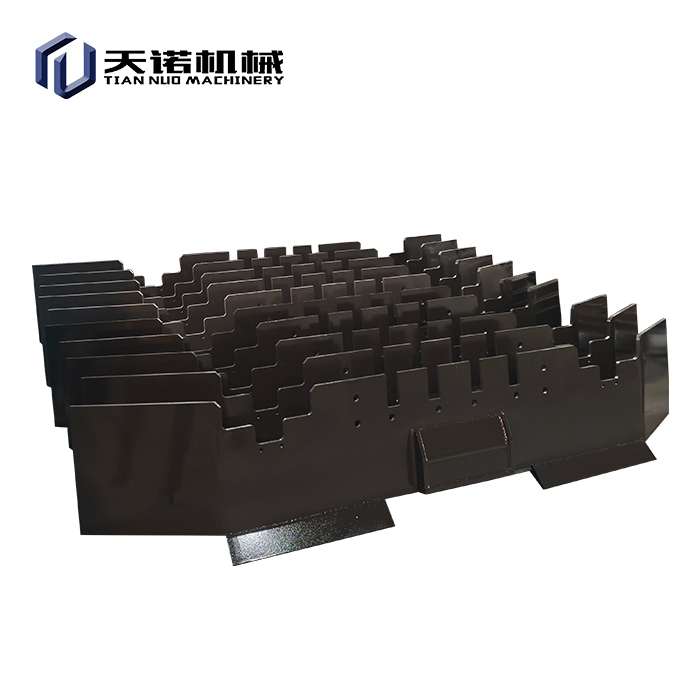

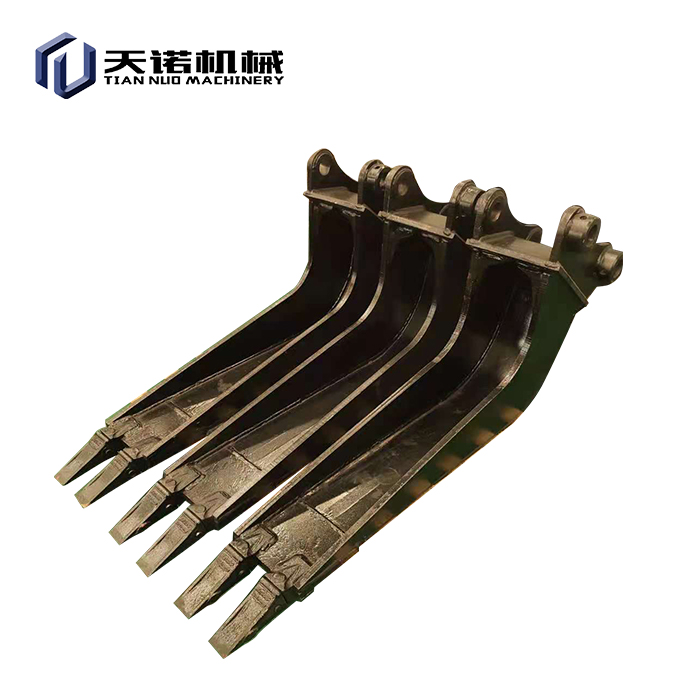

Details photos

Installing a Hi-Rail Excavator on a railroad excavator dramatically enhances its mobility, safety, versatility, and cost-efficiency. For any contractor involved in railway maintenance, construction, or emergency repair, the Hi-Rail system is no longer an optional accessory—it is an essential tool that improves productivity and guarantees safety.

By installing different tools like the sleeper changer, ballast tamper, rail clamp, ballast sweeper, and ballast plough, railway contractors can complete projects faster, safer, and at a lower operational cost.

By installing different tools like the sleeper changer, ballast tamper, rail clamp, ballast sweeper, and ballast plough, railway contractors can complete projects faster, safer, and at a lower operational cost.

Key features

Tiannuo Machinery’s Hi-Rail Excavator is engineered to meet the high standards of large and medium-sized enterprises in the railway industry. Our machine offers several advanced features:

Advanced Automation: With a high degree of automation, our sleeper changer reduces manual labor and speeds up the replacement process, making it an invaluable asset for any railway maintenance operation.

User-Friendly Interface: The intuitive design of our machine's interface allows operators to quickly learn and operate the equipment with minimal training, maximizing productivity.

Robust Construction: Built to withstand harsh environmental conditions, our sleeper changer delivers reliable performance even in extreme weather.

Enhanced Safety Features: Safety is paramount, and our sleeper changer is equipped with integrated safety mechanisms that protect both operators and machinery, significantly reducing the risk of accidents.

Low Maintenance Requirements: Designed with durability in mind, our sleeper changer requires minimal maintenance, which helps reduce long-term operational costs.

Benefits of our railroad excavator

Choosing Tiannuo Machinery’s Hi-Rail Excavator offers a range of benefits that directly address the needs of our target customers:

Increased Efficiency: The advanced automation of our sleeper changer significantly reduces the time needed for sleeper replacement, helping to accelerate project timelines and increase overall operational efficiency.

Improved Safety: With built-in safety features, our sleeper changer minimizes the risk of accidents, ensuring a safer working environment for your crew.

Cost-Effective Operation: The low maintenance requirements and long-lasting durability of our equipment translate to lower operational costs, providing excellent return on investment.

Versatility: Our sleeper changer is adaptable to various railway systems, making it suitable for diverse project needs and different types of sleepers.

Reliability: Designed to perform consistently in challenging conditions, our machine ensures uninterrupted operations, even in adverse weather.

How it works

The Hi-Rail Excavator from Tiannuo Machinery is designed for straightforward operation and high efficiency:

Positioning: The machine is aligned precisely over the track section where the sleeper needs to be replaced.

Sleeper Extraction: The old sleeper is carefully extracted using automated tools, minimizing any disruption to the surrounding track structure.

Sleeper Insertion: A new sleeper is inserted and secured with high precision, ensuring proper alignment and stability.

Final Adjustment: The machine ensures that the new sleeper is perfectly positioned and ready for immediate use, allowing the railway to be back in service as quickly

as possible.

Workshop display

Our cutting-edge workshop is where the product is meticulously designed and manufactured. We utilize the latest technology and adhere to stringent quality control standards to ensure that every machine meets the highest standards of performance and durability.

Workshop Image

Each product undergoes rigorous testing before it leaves our facility, ensuring that you receive a reliable and fully operational machine.

Testimonials

Our customers have experienced the transformative impact of Tiannuo Machinery’s Hi-Rail Excavator on their operations:

John D., Railway Contractor: “Tiannuo’s sleeper changers have drastically improved our efficiency. The safety features are particularly impressive, giving us peace of mind on every project.”

Sarah K., Government Agency: “We’ve saved both time and money with Tiannuo’s durable and low-maintenance equipment. Their support team is always responsive and helpful.”

Mark L., Logistics Company: “The versatility and reliability of Tiannuo’s sleeper changers have made our railway maintenance operations smoother and more effective.”

FAQ

Q: How long does it take to train operators on the Railway Changer?

A: Thanks to the machine’s user-friendly interface, most operators can become proficient within just a few hours of training.

Q: What maintenance does the product require?

A: The machine is designed for durability and requires only regular checks and basic maintenance to ensure long-term performance.

Q: Can the changer operate in extreme weather conditions?

A: Yes, our equipment is built to perform reliably across a wide range of environmental conditions, including extreme temperatures.

Contact us

Are you ready to enhance your railway maintenance operations with Tiannuo Machinery’s Hi-Rail Excavator ? Contact us today to discuss your specific requirements and receive a tailored solution that meets your needs.

Email : [arm@stnd-machinery.com]

YOU MAY LIKE

VIEW MORERailway Sleeper Changer

VIEW MORERailway Sleeper Changer_1767151461922.webp) VIEW MOREBallast Tamper(Gasoline Type)

VIEW MOREBallast Tamper(Gasoline Type) VIEW MOREBallast Scrapper

VIEW MOREBallast Scrapper VIEW MOREExcavator Hydraulic Rail Clamp

VIEW MOREExcavator Hydraulic Rail Clamp VIEW MOREExcavator Railway Ballast Cleaning Bucket

VIEW MOREExcavator Railway Ballast Cleaning Bucket VIEW MORERailway Excavator Ballast Plow

VIEW MORERailway Excavator Ballast Plow VIEW MOREsingle-head tamper

VIEW MOREsingle-head tamper VIEW MOREHigh-vibration hydraulic ballast tamping machine

VIEW MOREHigh-vibration hydraulic ballast tamping machine

_1763714376227.webp)

_1763714376263.webp)

_1763714376266.webp)