single-head tamper

Compatible Excavator Model: RRE15WP

Applicable Railway Track Gauge: 1520mm (Customization Available)

Vibration Frequency: 40Hz

Rotation Angle: 360°

Number of Tampers: 4

Clamping Range: 380-625mm

Maximum Motor Speed: 5000r/min

Motor Displacement: 56mL/r

Rated Motor Pressure: 400bar

- Product Description

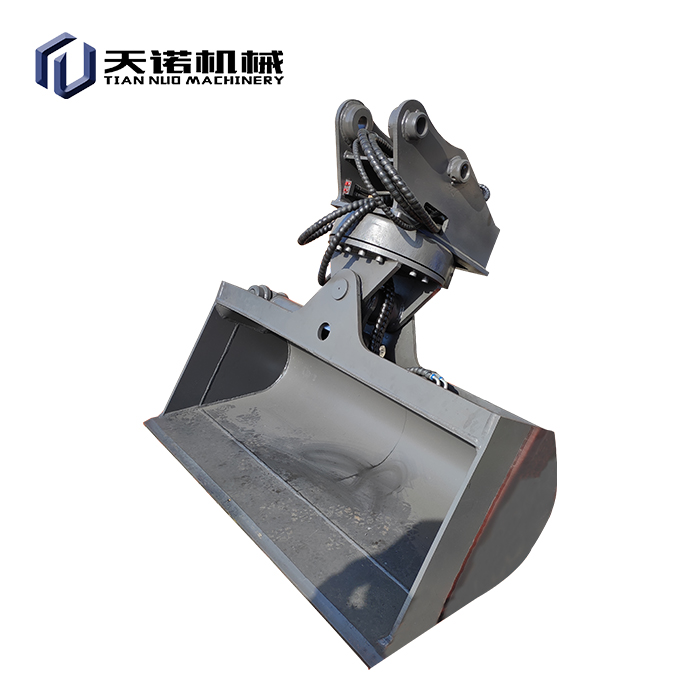

We specialize in the research and development and manufacturing of railway-specific engineering machinery, with our core product being railway excavator modification solutions. Through professional modification, we upgrade ordinary excavators into railway-specific equipment capable of stable movement on railway track beds, and specifically add high-efficiency attachments—single-head tamping machines—dedicated to the compaction and tamping of railway ballast.

Our modification solutions not only retain the excavator's flexibility and versatility but also enhance its adaptability to railway working conditions. They can efficiently complete key tasks such as track bed maintenance, sleeper positioning, and ballast compaction, helping railway construction and maintenance units improve operational efficiency and reduce labor costs. They are an ideal choice for railway line construction and daily maintenance.

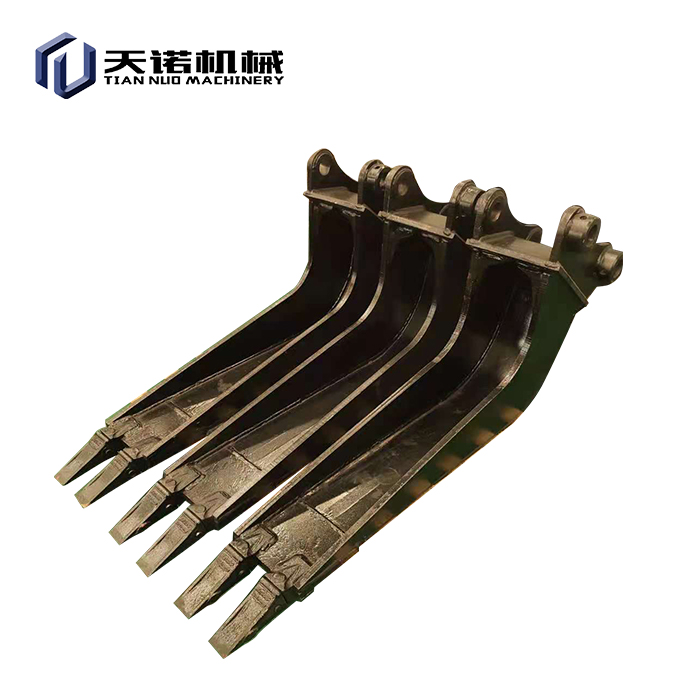

What is a single-head tamping machine?

Simply put, a single-head tamping machine is a mechanized handheld or machine-mounted tool specifically designed for railway track bed maintenance. Its core function is "tamping," which uses high-frequency, powerful vibrations to compact the loose ballast (crushed stone) beneath and around the railway sleepers, thereby fixing the sleepers, stabilizing the rails, and ensuring the smoothness and safety of the track.

You can think of it as an "extra-large, professional-grade vibratory tamper for stones."

| No. | Names | Units | |

| 1 | Applicable excavator tonnage | ton | 15 |

| 2 | Applicable track gauge | mm | 1520/1435/1067/1676 |

| 3 | Vibration frequency | HZ | 40 |

| 4 | Rotation angle | ° | 360 |

| 5 | Number of pickaxes | pcs | 4 |

| 6 | Maximum tamping depth | mm | 380 |

| 7 | Clamping range | mm | 380-625 |

| 8 | Maximum motor speed | r/min | 5000 |

| 9 | Motor displacement | ml/r | 56 |

| 10 | Motor rated pressure | bar | 400 |

Working Principle:

Vibration and Compaction: The tamping machine head (usually a pair of clamping pick arms or vibratory rods) generates high-frequency mechanical vibration under hydraulic or electric drive.

Batter Insertion: The vibratory pick arms are inserted into the ballast on both sides of the sleeper.

Compaction Process: Under the combined action of vibration and a certain amount of downward pressure, the crushed stone particles around the pick arms rearrange, reducing the gaps between them, thus becoming denser and more secure.

Sleeper Lifting: During the ballast compaction process, the sleepers are actually slightly lifted to the design elevation, and their underside is firmly supported.

Main Features and Advantages:

High Precision: Accurately controls the tamping position and force, ensuring that the track geometry (such as gauge, level, and elevation) meets high standards.

High Efficiency: Compared to traditional manual tamping, mechanized operations are faster, less labor-intensive, and significantly improve maintenance efficiency.

Good Results: Uniform ballast compaction and stable sleeper support effectively extend the track maintenance cycle and improve train operation smoothness and safety. Adaptability: It can be flexibly mounted as an attachment (accessory) on excavators, railway engineering vehicles, or specialized tamping machines to adapt to different working conditions.

Your factory's core business—converting excavators into railway excavators and adding single-head tamping machines—perfectly embodies this attachment application. This transforms an ordinary excavator into:

A multi-functional railway maintenance platform: Retaining basic functions such as excavation, handling, and hoisting, while also possessing professional track tamping capabilities.

A flexible and efficient solution: Particularly suitable for scenarios where large tamping trains are difficult to operate in, or where it's overkill, such as station maintenance, partial track repair, and turnout tamping. Your customers can obtain a specialized piece of equipment capable of handling multiple tasks at a lower cost.

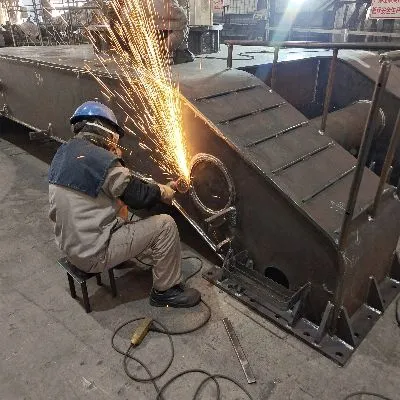

Workshop Display

ur cutting-edge workshop is where the product is meticulously designed and manufactured. We utilize the latest technology and adhere to stringent quality control standards to ensure that every machine meets the highest standards of performance and durability.

Each product undergoes rigorous testing before it leaves our facility, ensuring that you receive a reliable and fully operational machine.

Q: What is a railway excavator modification?

A: It's a specialized process of converting standard excavators to travel and operate on railway tracks, primarily for maintenance tasks. The core feature is the integration of a single-head tamping tool for efficient track bed compaction.

Q: What is the single-head tamper used for?

A: The tamper is designed specifically for compacting and consolidating railway ballast (the crushed stone beneath tracks), ensuring stable support for sleepers and rails, and maintaining track alignment and safety.

Q: How long does it take to train operators on the railway excavator?

A: Thanks to the intuitive control system and familiar excavator base, most operators can become proficient in railway-specific functions within just a few hours of training.

Q: What maintenance does the modified excavator require?

A: The modification is built for rugged use and requires only routine checks—similar to standard excavators—along with periodic inspection of the rail travel system and tamping attachment to ensure lasting performance.

Q: Can it operate in extreme weather conditions?

A: Yes. The machine is engineered to work reliably in varied environments, including high heat, cold, and other challenging weather conditions common in railway operations.

Q: Is the excavator still usable for normal digging tasks?

A: Absolutely. The modification focuses on adding rail mobility and a specialized attachment. The excavator retains its original digging and lifting functions, making it a versatile multi-purpose machine.

Contact Us

Are you ready to enhance your railway maintenance operations with Tiannuo Machinery’s single-head tamper? Contact us today to discuss your specific requirements and receive a tailored solution that meets your needs.

YOU MAY LIKE

VIEW MOREHi-Rail Excavator

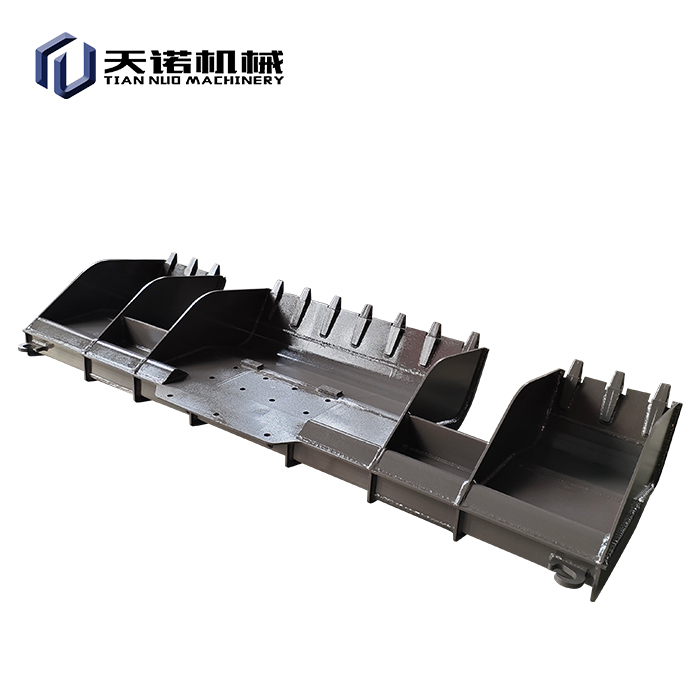

VIEW MOREHi-Rail Excavator VIEW MOREExcavator Railway Ballast Cleaning Bucket

VIEW MOREExcavator Railway Ballast Cleaning Bucket VIEW MORERail Transfer Guide(Rail Threader)

VIEW MORERail Transfer Guide(Rail Threader) VIEW MOREDegree Rotating Hydraulic Tilt Ditching Bucket

VIEW MOREDegree Rotating Hydraulic Tilt Ditching Bucket VIEW MORERailway dustpan excavator bucket

VIEW MORERailway dustpan excavator bucket VIEW MORERailway Excavator Cleaning Bucket

VIEW MORERailway Excavator Cleaning Bucket VIEW MORELong rails transfer carrier

VIEW MORELong rails transfer carrier VIEW MOREExcavator Hydraulic Rail Clamp

VIEW MOREExcavator Hydraulic Rail Clamp

_1766456518238.webp)

_1766456518262.webp)

_1766456518347.webp)

(1)_1766456518365.webp)

_1766456518490.webp)