Wheel Sleeper Replacement System

Engine: Yuchai YC4D125-T130

Travel Speed: 28km/h

Tread Width: 9.00-20

Type: Highway, Railway

Wheel Track: 1944mm

Sleeper Opening: 630mm

Clamping Weight: ≤1.6t

Rail Wheel Gauge: Customizable

- Product Description

Founded in 2014, Shandong Tiannuo Construction Machinery Co., Ltd. is a high-tech enterprise specializing in the design, research and development, and production of excavator modifications. The company focuses on the railway, mining, and construction industries, providing customers with customized, high-performance excavator modification solutions.

As an industry innovation leader, the company currently holds over 100 patents, and its core technical team possesses more than 10 years of experience in excavator modification. Furthermore, it has obtained authoritative certifications such as the three-system certification and high-tech enterprise certification, ensuring product quality through a standardized management system.

What is a Wheel Sleeper Replacement System?

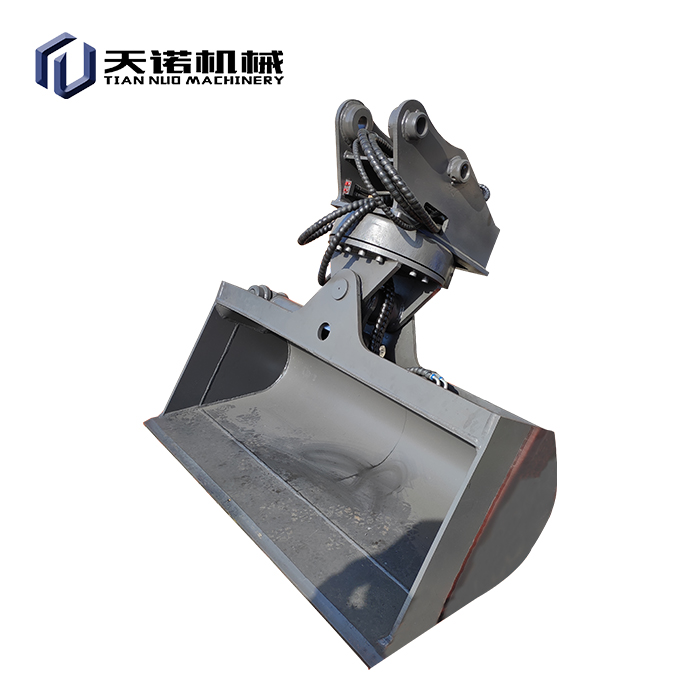

It's not a brutal "open-heart surgery," but a precise "minimally invasive surgeon." The railway sleeper replacement machine is the culmination of modern railway maintenance wisdom. Its mission is to silently and efficiently replace the old sleeper (railway sleeper) with millimeter-level precision during train intervals.

Traditional large-scale roadblocks and manpower-intensive tactics are a thing of the past. This steel surgeon can precisely locate, grab the old sleeper, insert the new one, and adjust its geometry—a series of actions performed flawlessly. Its greatest value lies in maximizing the "life" of the railway line with minimal "trauma"—minimizing the impact of construction on the railway's vital transport capacity, allowing safety and efficiency to coexist in a highly efficient replacement process.

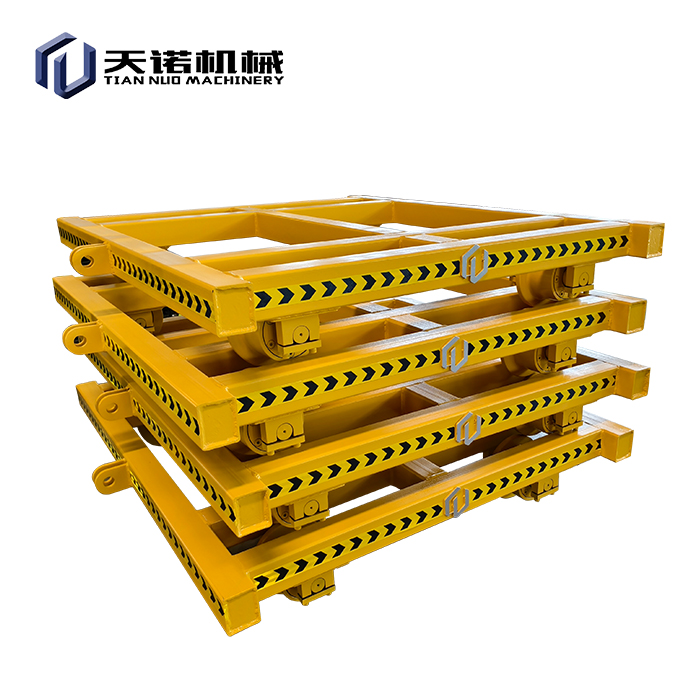

| NO. | Name | unit | Values |

| 1 | Applicable models | ton | RRE15WP |

| 2 | gauge | mm | 1520/1067/1435/1000 |

| 3 | Speed of replacing sleepers | pcs/hour | 30-60 |

| 4 | sleeper clamp opening | mm | 630 |

| 5 | sleeper width | mm | 2900 |

| 6 | Clamp rotation angle | ° | 360 |

| 7 | Hydraulic oil flow | L/min | 40-70 |

| 8 | Work pressure | Mpa | 14 |

| 9 | weight | kg | 1100 |

[Making Railway "Metabolism" Keep Pace with the Times]

Railways also need metabolism, and sleepers are their regularly updated "skeleton." The sleeper-changing machine is the driving engine of this metabolic revolution.

It redefines the rhythm of maintenance: no longer a long, cyclical overhaul, but a precise, rapid, and continuous "preventative update." Like a sophisticated automated production line, it achieves a seamless "one-click" operation of removing old sleepers, laying new ones, and calibrating track gauge, increasing efficiency dozens of times that of manual labor. This is not only about speed, but also about gaining valuable "maintenance windows" for the lines on an increasingly dense transportation schedule, ensuring the railway network remains at its peak condition.

[Replacing the Skeleton Amidst an Uninterrupted Pulse]

The railway is the pulse of the nation, its mission never ceasing. The railway sleeper changing machine is the master of this paradox—how to replace the skeleton supporting it amidst a constantly beating pulse?

The answer lies in ultimate synchronization and precision. This machine is a highly integrated symphony orchestra: digging, hoisting, aligning, securing… all actions work in concert under the command of a pre-programmed sequence, dancing with the busy train schedule. It protects not only the sleepers, but also that seemingly impossible task: ensuring that "change" itself is no longer the enemy of "continuity."

The operation of a railway sleeper replacement machine resembles a precisely choreographed four-step process:

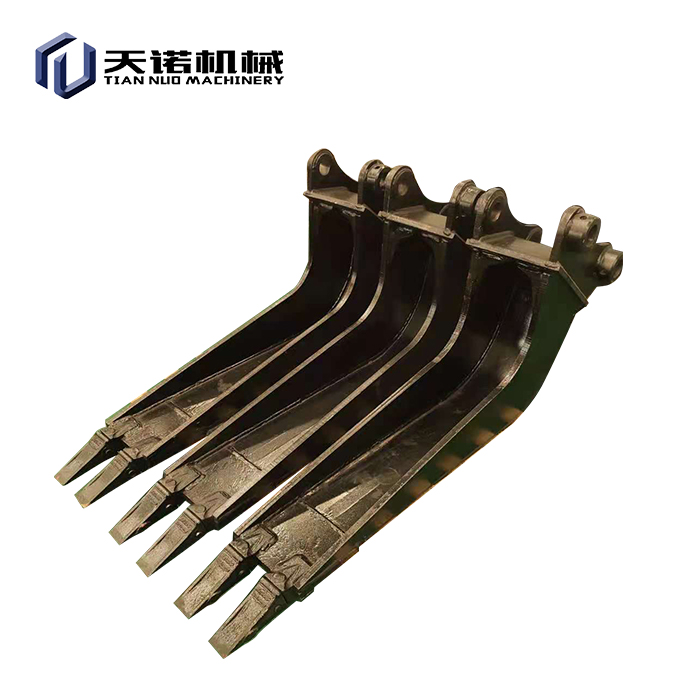

**Precise Positioning and Unlocking:** The machine travels along the track to the sleeper to be replaced and precisely positions it. Powerful grippers, like robotic arms, "grasp" the rail, slightly lifting it to "untie" the sleeper from the ballast and quickly detach it from the rail's fasteners.

**Old Sleeper Removal and Cleaning:** A specialized gripping device firmly grasps the old sleeper, horizontally extracting it and moving it to a temporary storage area on the side of the machine or onto a conveyor belt. Simultaneously, a cleaning device tidies up or removes the old ballast beneath the sleeper, preparing a flat and firm "bed" for the new sleeper.

**New Sleeper Insertion and Alignment:** The new sleeper is precisely transported from the machine's storage area or an accompanying auxiliary car to the original position of the old sleeper. The machine places it in place with millimeter-level precision, ensuring perfect alignment with the rail's connection holes.

**Securing and Resetting:** The rail is placed back onto the new sleeper, and the fasteners are automatically tightened. Finally, the ballast is backfilled or vibrated to compact it, ensuring the new sleepers are firmly embedded in the track. The entire process is efficient and seamless, maintaining the track geometry, allowing trains to resume safe operation in a very short time.

Workshop Display

Our manufacturing facility at Tiannuo Machinery is equipped with state-of-the-art technology and adheres to strict quality control standards. Every Ballast Blaster Undercutter we produce undergoes rigorous testing to ensure it meets our high standards of performance and durability. We take pride in delivering machines that are ready to perform from the moment they leave our workshop.

Testimonials

"Efficiency improvements beyond imagination!" - Wang, Team Leader, Track Maintenance Section

"Since introducing this track excavator, our sleeper replacement time has been reduced by nearly 50%. It can move quickly and accurately on the tracks, rapidly completing excavation, debris removal, and backfilling—it's simply a miracle worker for track overhauls. Its stability and safety have withstood our rigorous working conditions."

"A reliable partner for emergency repairs, where every second counts!" - Zhang, Engineer, Metro Operations Company

"Last time, there was a potential collapse risk in the tunnel, and the window for emergency response was extremely short. This machine quickly moved along the track, rapidly cleared the debris, and stabilized the foundation, buying valuable time for subsequent repairs. Its rapid mobility and powerful digging force played a decisive role in the repairs."

"Multi-functional, flexible, and efficient!" - Railway Maintenance Service Company Manager Li: "We mainly undertake various track maintenance services. This track excavator can not only quickly replace sleepers, but also perform ballast shaping, ditch cleaning, and other operations by changing attachments. It can travel directly on the track without damaging the track bed, and its relocation speed is extremely fast, greatly improving the comprehensive service capabilities and efficiency of our train crew."

FAQ

Q: How much training is required to operate the Railway Track Excavator?

A: Most operators can learn to operate it effectively within a short training period, as the machine features an intuitive control system and simplified workflow.

Q: What kind of maintenance does the machine require?

A: The machine is built for durability and requires only routine inspections and basic servicing to maintain reliable performance in demanding rail environments.

Q: Is the Railway Track Excavator suitable for emergency repair tasks?

A: Yes, it is designed for rapid deployment and can perform efficiently in emergency scenarios such as track rehabilitation and rapid sleeper replacement.

Q: Can the machine work on different types of railway tracks?

A: Yes, it is adaptable to standard gauge and other common rail systems, with adjustable undercarriage and positioning features to suit various track configurations.

Contact Us

Ready to enhance your railway maintenance operations with Tiannuo Machinery’s Wheel Sleeper Replacement System? Contact us today to discuss your specific needs and receive a customized solution.

Email: [arm@stnd-machinery.com]

_1766383935129.webp)

_1766383813593.webp)

_1766383813559.webp)

_1766383813627.webp)